Avionics Systems

Delivering Open

At GE Aerospace, our civil and military customers are the focus of our innovative solutions.

Extensive experience across the aerospace industry keeps us focused on security, safety, and optimization.

Our open systems architectures bring new options to both the civil and military fleets, old and new, that will enable aircraft to keep pace with new technology.

Customers can expect through-life support to maximize aircraft and crew efficiency.

GE Aerospace’s Digital Backbone provides an affordable and adaptable avionics system architecture that meets the needs of next-generation aircraft platforms.

This digitally engineered system lowers development lifecycle costs and allows for reuse.

Networking Capabilities

Flexible nodal exchange

• Enables rapid platform upgrades and reconfiguration.

• Optimal and scalable size, weight, and power.

• Standards-based data interchanges for rapid system upgrades.

Deterministic network switching

• Flexible high-speed networking with options for Ethernet and Time Sensitive Networking (TSN).

• Adaptable security and bandwidth capabilities.

Full end-to-end development toolset

• Flexible integration independent of the OEM

• Compliant with Modular Open System Architecture (MOSA)

• Derived from fielded commercial solutions

We offer a full portfolio of versatile and rugged embedded networking systems that scale to satisfy a wide-range of applications

• Designed for critical high design assurance applications

• Built for the most demanding environments

• Utilizes standards-based open architecture

• Fully configurable with advanced tools

• Compatible with many interfaces including Ethernet, AFDX®, ARINC664, and Time Sensitive Networking

Current Offerings

Future Offerings

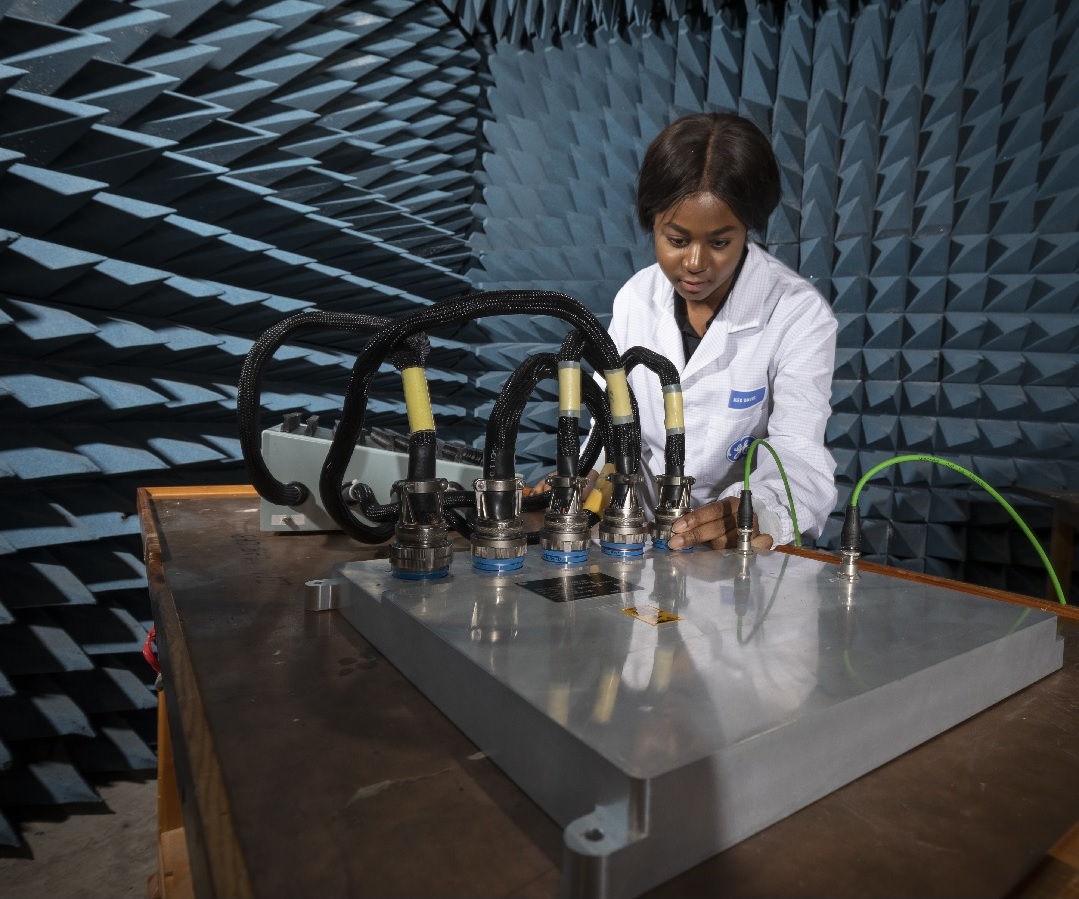

GE Aerospace’s Health Awareness System is an end-to-end solution that delivers proven health management solutions. The system provides a holistic picture of configuration, health, usage, and maintenance data.

Flight path optimization, accuracy, and connectivity are at the core of GE Aerospace’s flight management systems reducing time, fuel consumption and emissions across numerous civil and military platforms with the longest running navigation database service in the industry and training solutions from desktop simulation to real hardware.

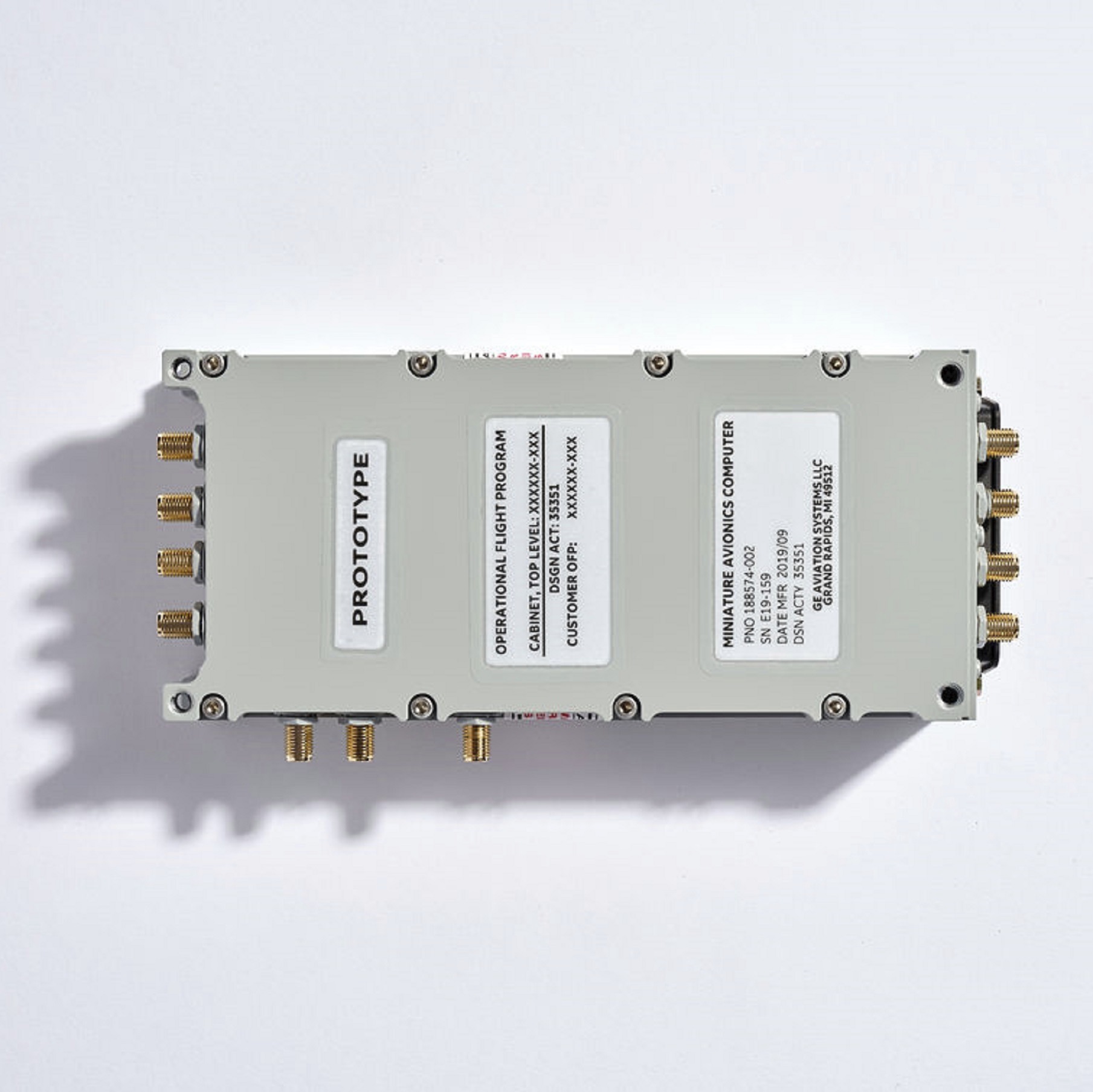

GE Aerospace sets the open computing standard with a full range of versatile and rugged embedded computing systems for vehicle and mission computing applications.

Proven open architectures in both civil and military implementations with decades of flight hours provide our customers with ownership of their embedded systems.

Computing Systems

Vehicle Mission Computers

Integrated Modular Avionics

M-Series

• M-100

• M-256

• 787

• 777X

• ARINC 653 Time and Space partitioned environments allow for varying Design Assurance Levels

• Ruggedized products for the most demanding environmental conditions

• Standards-based open architectures

• Tools and support to host 3rd party applications

Input/Output and Interface Controller

Remote Interface Units (RIUs) provide a family of low cost, line replaceable items or sub-modules which are designed to be installed in remote locations, away from the main aircraft processing resource but near air-vehicle subsystem(s).

Remote I/O Portfolio

• Sometimes referred to as data concentration or remote data concentrators

• Provides autonomous local closed loop control

• Utilized between third party units without compatible interfaces to provide a “translation” function

• Industrial Remote Interface Unit (IRIU) 240

• Remote Interface Unit (RIU) 100

• Remote Interface Unit (RIU) 303

Reference & Advanced Navigation Portfolio

The cornerstone of GE Aerospace’s offering is the Inertial Reference Units (IRU), offering navigation-grade inertial performance for more than 30+ years. The IRU is most often utilized for platform navigation, system stabilization, and pointing applications.

Current installations include:

• Gun stabilization systems

• Accurate heading/pointing systems

• Autonomous land vehicle position/navigation

• Blended autonomous/GPS aided navigation

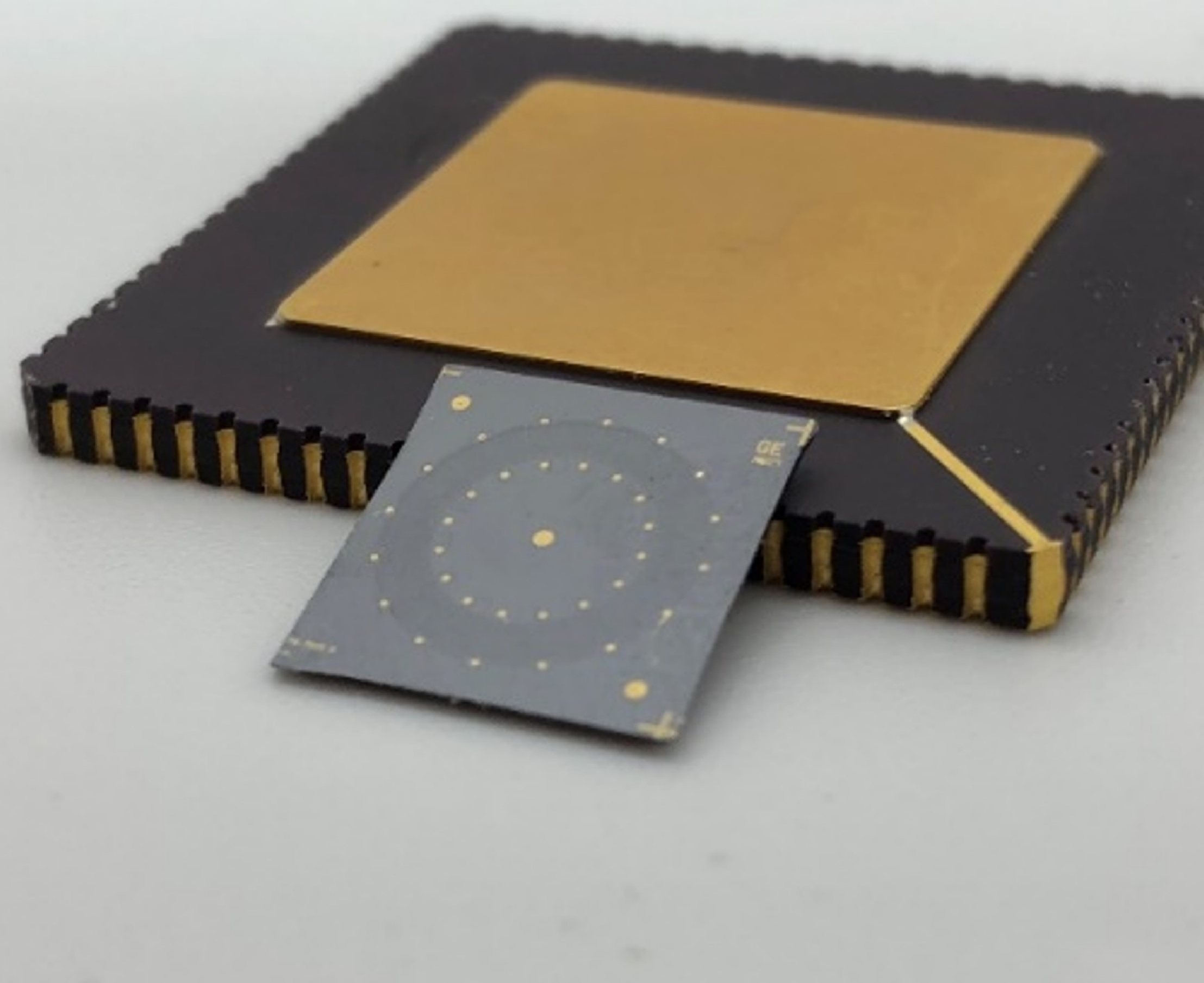

Our MEMS-based IMU offers high-end tactical grade performance in a smaller package when compared to existing Fiber Optic Gyro (FOG) and Laser Ring Gyro (RLG) products

• 16 cubic inch footprint

• Dynamic software-only reconfiguration of the Inertial Navigation System (INS) for different environments.

• Compliant to Open interface standards such as ASPN/PNTOS, aligning to Army PNT reference architectures.

• Capable to with stand harsh environments such as high vibration and high shock.

GE Aerospace’s A-PNT solution is software based and its strict adherence to MOSA enables it to be easily integrated with likewise-conformant navigation, computing and sensors on existing platforms. This concept provides customers maximum flexibility to design an A-PNT system that offers exactly what they need and nothing extra.

The APNT software can matched with a MEMS-based IMU for inertial reliability.

• Modular design plugs into pntOS

• FACE™ stack enables portability with likewise conformant computing resources

• ASPN implementation enables rapid deployment of new sensor technologies

• Application software implements the System Controller, Fusing Engine (Complementary KF) and Integrity Monitors

Controls & Displays

Our latest generation Open Display Platform is a modular, open system that meets MOSA and FACE™ standards with a flexible touchscreen interface and the ability to host multiple GE and 3rd party applications.

Controls & Displays Portfolio

Touchscreen Open Display Platform

This up-and-coming product is the latest in technology and can be configured for your platform:

Open System

• Modular Open System Architecture (MOSA) provides a true open system

• FACE™ aligned system meets the latest standards.

• Host GE Aerospace and/or 3rd Party applications in an ARINC 653 environment.

Display Technology

• Configure Display Head Size and Bezel customized for your platform without affecting the backend electronics.

• Utilize Capacitive, Resistive or Light-based Touchscreen technology.

• Go with a traditional 7” or 9” Multi-purpose Display Control Unit with a keyboard.

Connectivity

• Capable of driving additional external dumb displays or cross connect for redundancy.

• Traditional aircraft interfaces such as ARINC 429, MIL-STD-1553, Ethernet, Time Sensitive Networking, RS-232/422/485, ARINC 818, and discrete IO.

GE Aerospace has a legacy of delivering a variety of MCDUs based off of 2 core designs with traditional display, line select keys and keyboard with some level of configurability:

• 9” MCDU

• 7” MCDU

Current supported platforms can be found on our Navigation and Guidance page.

Our 4th and latest generation Integrated Standby Instrument is now available, with reduced weight and power consumption. The unit is a standard 3x3 inch (3ATI) format, with a flexible range of custom options.

• Designed, qualified to deliver high performance and accuracy whilst operating within extreme environments.

• High precision integrated sensors detect attitude rates and accelerations.

• Integrated pitot and static sensors generate airspeed and altitude.

• High resolution AMLCD NVIS compatible display combined with patented software rendering techniques provide a clear readable image across the whole viewing angle and dimming range.

Data Transfer

GE Aerospace is committed to providing the most reliable and innovative equipment on the market.

Data Transfer Systems Portfolio

Advanced Data Transfer Equipment Mk-II

• 1000 Mbps transfer speeds

• FIPS 140-2 encryption

• Gigabit Ethernet port

• Fibre Channel Port

• Audio/Video Recording

• MIL-STD 1553 Port

Advanced Data Transfer System Mk-II

• 1000 Mbps transfer speeds

• FIPS 140-2 encryption

• Gigabit Ethernet port

• Digibus GAM-T101

• MIL-STD 1553 Port

Advanced Data Transfer Cartridge Mk-II

125 MB/s read/write, FIPS 140-2 encryption, 2 Gigabit Ethernet port, same form factor and mechanical interlocks proven on the thousands of data transfer cartridges fielded by GE Aerospace since 1981

Enhanced Data Transfer Cartridge Mk-II

• Flight proven

• 256GB mass memory

• (2) Gigabit Ethernet Ports

High Speed Data Transfer System

• Industry leading read/write speeds

• Up to 64TB of data storage

• 2 redundant 40GB Optical or Copper Links

• Data Security via FIPS140-3

• Industry Standard NVME Interfaces

SafeKeep

• Manned and unmanned applications

• Secure data with encryption

• High speed upload and download of recorded data, hosting of user

developed applications,

• User upgradeable Data Transfer Cartridges

• Form-fit for rotorcraft applications

Airborne Video Solid State Recorder

• (4) RS-170 NTSC Video,

• (2) Audio Input Channels,

• (1) RS-422 Serial Port

• MIL-STD 1553 Port

Data Transfer Equipment Mass Memory Video Recorder

• 1GB Mass Memory Unit

• RGB Video Input

• Analog Audio Input

• Fibre Optic Data Bus

• MIL-STD 1553 Port

Advanced Data Transfer Cartridge

• 64 MB Battery Backed

• Mission Memory

• 48 GB of Mass Memory

Advanced Data Transfer Unit

• MIL-STD 1553 Port

• Digibus GAM-T101

• 100BaseT Ethernet

Upgraded Data Transfer Unit

The Following Part Numbers:

• 35Y1000000

• 35Y1000001

Mega Data Transfer Cartridge

The Following Part Numbers:

• 3961000000-12

• 3961000001-02

• 3961000001-12

• 3962000000-12

Data Transfer Receptacle

The Following Part Numbers:

• D1321000000

Data Transfer Cartridge

The Following Part Numbers:

• 7462000001

• 7462006001

• 7462020000

• 7462020001

• 7462020002

• 7462020004

• 7462020005

• 7463002001

• 7463004000

• 7463004001

• 7463004003

• 7463004015

• 7463004016

• 7463006000

• 7463006001

• 7463006003

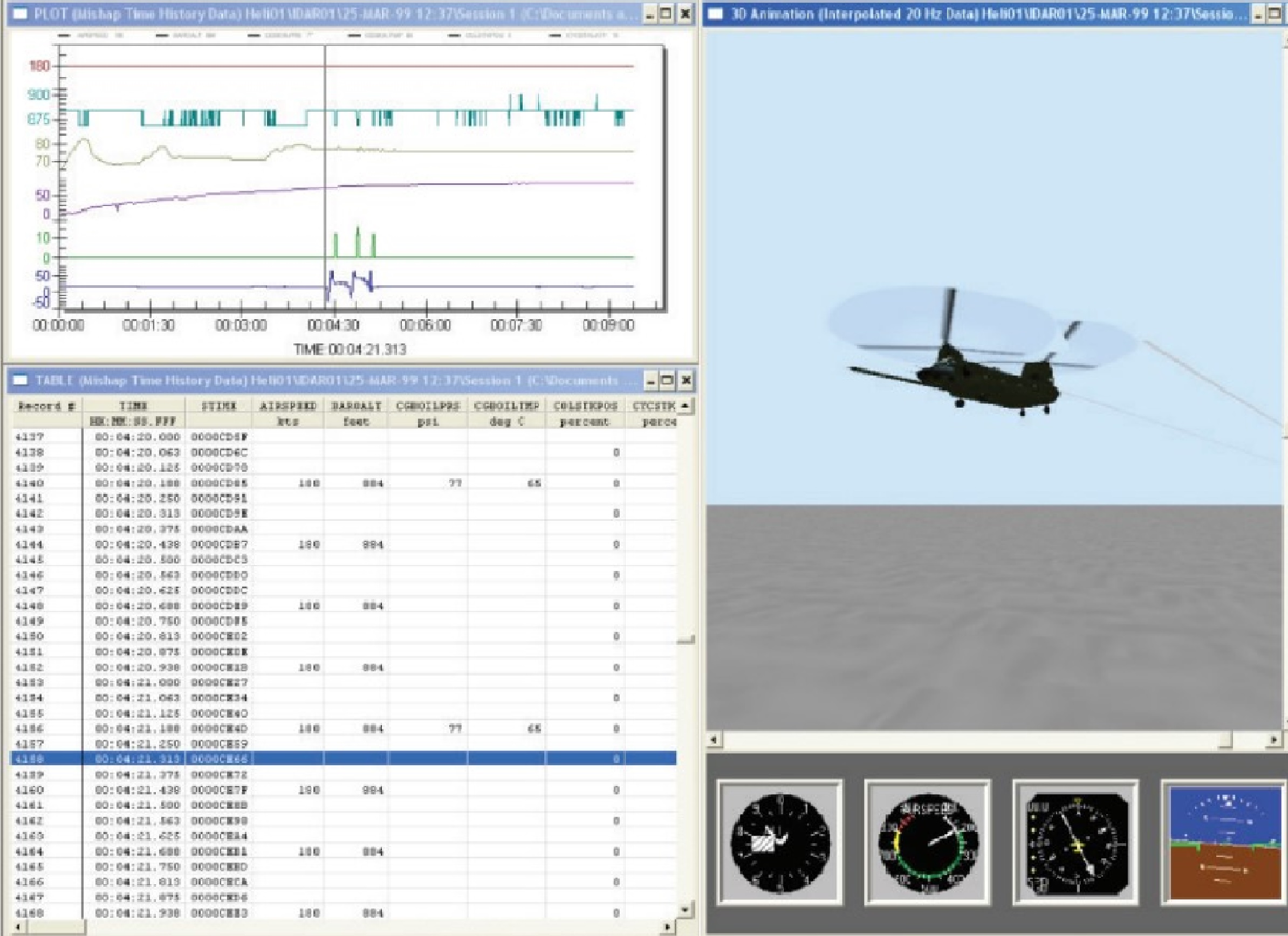

Flight Data and Cockpit Voice Recorders

Our broad portfolio of customizable data recorders offers a wide range of solutions for civil and military fixed and rotorcraft applications.

Recorder Portfolio

FAQs

• End-to-end solutions to acquire, transfer, process and analyze flight and voice data

• Support the full mission cycle with safety, maintenance, flight quality assurance

• Training information systems for civil and military customers

Stores Management

Customers can take advantage of our experience and wide portfolio to meet their affordability, capability and schedule requirements.