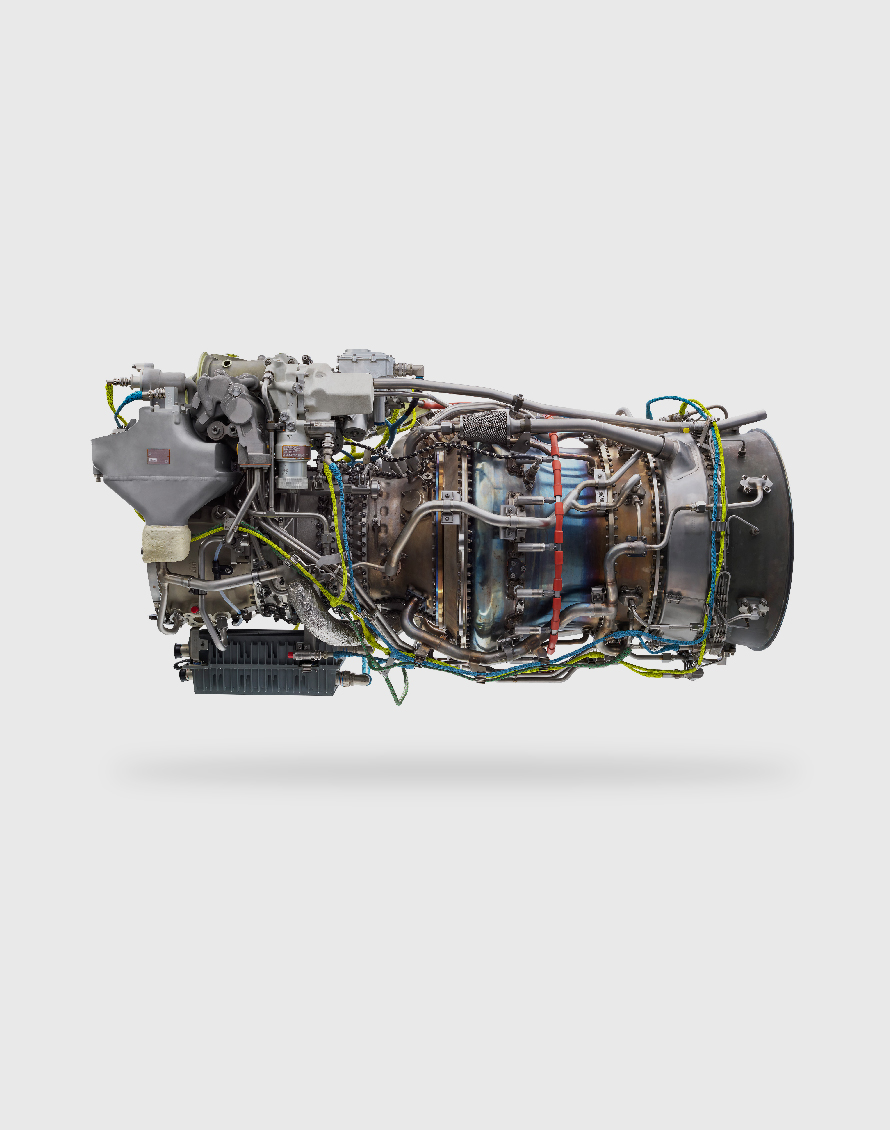

T408 Turboshaft engine

Ready to

serve

GE Aerospace’s latest turboshaft engine, developed for heavy lift applications, is now demonstrating game-changing power.

Measuring up

When compared to its predecessor – GE's T64 turboshaft engine powering the CH-53E Super Stallion aircraft – the T408 provides transformational performance improvements. To date, the T408 has logged more than 11,000 hours of ground and flight test in support of a variety of Department of Defense (DoD) programs.

57

%More Power

18

%Better specific fuel consumption

63

%Fewer Parts

SIMPLE

Reliable Fix-Forward Design

Ready to Serve

Qualified and in service today, this 7,500-shaft horsepower (shp) class turboshaft engine offers maximum power with its cutting-edge technologies and modern design innovations. The T408 was designed to deliver unsurpassed mission capability for a variety of rotorcraft, tiltrotor, and turboshaft applications with a rugged, simple, and easily maintainable design.

The T408-GE-400 is a powerful and technologically advanced engine powering the three-engine Marine Corps’ CH-53K King Stallion heavy-lift helicopter. Delivering 7,500 shp per engine, its unparalleled reliability meets warfighters’ heavy-lift requirements.

The T408-GE-400 is a powerful and technologically advanced engine powering the three-engine Marine Corps’ CH-53K King Stallion heavy-lift helicopter. Delivering 7,500 shp per engine, its unparalleled reliability meets warfighters’ heavy-lift requirements.

External payload

The T408 gives the CH-53K helicopter the power to carry a 27,000-pound external load over a mission radius of 110 nautical miles in hot weather conditions. That’s nearly triple the external load carrying capacity of the current CH-53E Super Stallion aircraft.

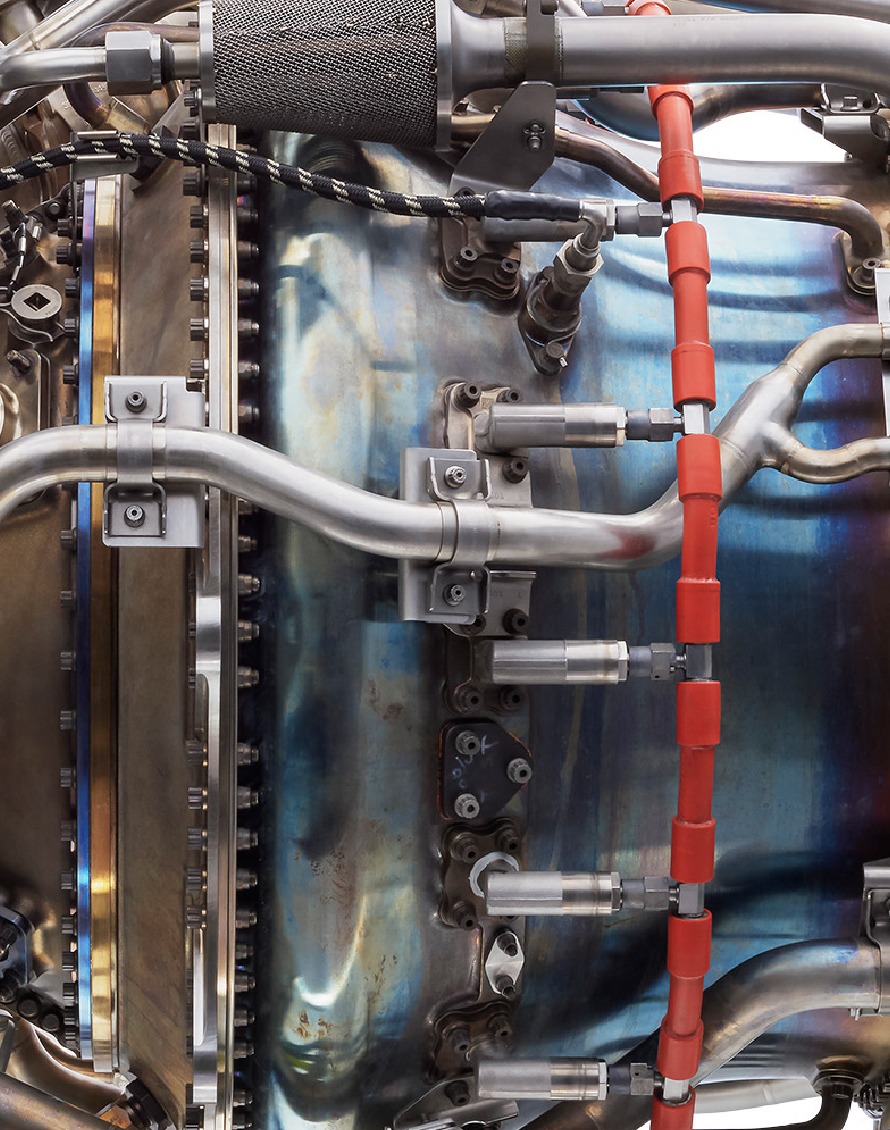

Proven technology

The T408 combines breakthrough technologies, innovative cooling schemes, and modern-day durability to deliver numerous mission-critical advantages in the world’s harshest operating environments.

GE’s T408 is equipped with Full Authority Digital Engine Control (FADEC) with prognostics and health management to improve performance and reduce maintenance cost.

GE’s T408 is equipped with Full Authority Digital Engine Control (FADEC) with prognostics and health management to improve performance and reduce maintenance cost.

Low operating & support costs

- Long-life parts reduce the need to replace high-dollar parts at overhaul

- Reliable components improve time-on-wing

- Low fuel consumption delivers significant savings over the life of the engine

- On-condition maintenance

- Logistics infrastructure is already established with the U.S. Navy

News

Israel picks CH-53K as next heavy-lift helicopter

CH-53K King Stallion logs first successful fleet mission

Upgrading CH-47 Chinook with more powerful GE T408 turboshaft is feasible: US Army

Lessons learned from T408 program to help guide future Army aircraft

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.