GE Aerospace 2024 Annual Report

GE Aerospace 2024

Annual Report

Dear Fellow Shareholder,

2024 was a historic year for GE Aerospace as we took flight as an independent, standalone public company. Ever since that day, we have proven we were meant to fly.

The promise of becoming a standalone company was that our future would be wholly in our hands—ours to define and ours to create. But we also recognize our takeoff was made possible by our history. The engineers who built the first U.S. jet engine; the world’s first high bypass turbofan; the first turbine engine certified by the U.S. Federal Aviation Administration (FAA) for civil helicopter use; the largest and most powerful commercial aircraft engine; and, most recently, the first three-stream adaptive cycle engine. The maintenance, overhaul, and repair (MRO) teams who changed the business model to not just design and manufacture high quality engines, but to also service those engines through the lifecycle. We stand on the shoulders of those giants who came before us. Those who were always striving for better—not for the sake of being first, but for our customers who deserve the best. And that’s the point.

In this, our first annual shareholders’ letter, we proudly report that GE Aerospace is a global leader in propulsion, services, and systems with an installed base of 70,000 commercial and defense engines and $35 billion in adjusted revenue*—approximately 70% of which is driven by aftermarket services.

Our 53,000 employees, serving customers in approximately 120 countries, come to work every day to invent the future of flight, lift people up, and bring them home safely. Right now, there are approximately 950,000 people in the sky with technology made by GE Aerospace and our joint venture partners under wing. Our work matters to the world, and we care deeply about how we do it—with a relentless focus on safety, quality, delivery, and cost (SQDC)— always in that order.

2024 marked the 35th anniversary of a defining moment in GE Aerospace’s culture: the tragic United Airlines Flight 232 crash in Sioux City, Iowa, which was caused by a series of failures following a cracked fan disk in one of our engines. While GE Aerospace still carries the weight of the 112 lives lost on that day, we believe what has come from it—specifically the creation of our Safety Management System (SMS)—has made the industry safer. GE Aerospace’s SMS is a robust framework that defines the criteria for the safety of flight and reinforces our culture of open reporting, where every employee is expected to raise a concern. Paired with SMS is our Quality Management System (QMS), designed to support our teams in producing quality parts to specification every time while complying with all regulations. Importantly, the teams who lead implementation of the SMS and QMS are not held to any financial performance expectations. Together the SMS and QMS set clear standards and are the best way we know how to operationalize flight safety.

When it comes to safety, we never compete. It is a team sport and an industry-wide effort.

In that spirit, this year, we formed the Aviation Supply Chain Integrity Coalition with leaders from across the aerospace industry in the U.S. and Europe to help prevent unauthorized parts from entering the aviation supply chain and to strengthen the supply chain’s overall integrity. Aligned with the coalition’s recommendations, GE Aerospace digitized 18 million past MRO records. Today, when we perform maintenance on an engine at a GE Aerospace MRO shop, key records are digitalized and artificial intelligence (AI) helps verify the validity of key data fields, flagging discrepancies in real time.

Flight is an incredible responsibility. Everyone at GE Aerospace owns safety—at all levels of the organization from the shop floor to engineering and sourcing to the leadership team. It will always come first.

Defining flight for today, tomorrow, and the future

Arriving at the New York Stock Exchange (NYSE) on our memorable launch day in April created a powerful moment of reflection for us all. The NYSE and GE have been together for more than 100 years, dating back to our founder Thomas Edison. Edison made his early reputation as an inventor by designing an improved self-winding stock ticker and earned enough money from that invention to establish his famed Menlo Park Lab—the foundation upon which Edison built GE. It’s easy to imagine Edison all those years ago walking the same halls, excited for the day ahead while also looking to a bright future. What an inspiring gift it is to carry on that legacy of innovation, passion, and purpose set all those years ago at GE Aerospace today.

Our vision at GE Aerospace is to be the company that defines flight for today, tomorrow, and the future. That sounds aspirational, and it is. But it is also an opportunity firmly within our grasp as the manufacturer of the industry's largest and growing commercial and defense engine fleet.

Today, we are focused on service and readiness. Our aftermarket services business is critical in keeping our customers’ fleet in the air longer and meeting their needs while ensuring world-class safety and reliability.

At the same time, we are preparing for tomorrow, working hand-in-hand with our customers to modernize and expand their fleets. We are experiencing a tremendous demand cycle with equipment and services backlog strong at more than $170 billion. The onus is on us to meet the market’s needs with the highest quality standards and with greater predictability.

Inventing the future of flight requires investment today. This year, including customer and partner funding, we spent approximately $2.7 billion in research and development (R&D), driving breakthroughs in Open Fan engine architecture, hybrid electric propulsion, hypersonics, small engines for unmanned applications, and next-generation adaptive cycle engines.

Our confidence to deliver for today, tomorrow, and the future is due to our culture rooted in three key ideas: respect for people, continuous improvement, and customer driven. As part of our launch as a standalone public company, we made every employee an owner of GE Aerospace through a special one-time equity award. We are accountable to each other, our customers, and our shareholders to always find a better way and climb higher together.

Sharing the NYSE opening bell podium with members of the GE Aerospace senior leadership team, along with Gail Thompson, Advanced Lead Engineer at our Grand Rapids Avionics facility, and Dan Darrell, Maintenance Specialist at our Evendale site, we were excited by the moment yet felt a huge sense of possibility for what’s to come. We are ready for the climb.

In 2024, GE Aerospace delivered a monumental year financially, marked by double-digit orders and adjusted revenue* growth, operating profit* up $1.7 billion and free cash flow* up $1.3 billion. Given the strength of our financial performance and balance sheet, we returned more than $6 billion to our shareholders, through over $5 billion of share repurchases and $1 billion of dividends.

Let’s take a closer look at how our businesses performed.

Commercial Engines & Services (CES)

With more than 45,000 engines in our installed base, GE Aerospace and our joint venture partners power three out of every four commercial flights, demonstrating our unmatched scale and scope across the world’s most successful and innovative aircraft platforms.

2024 was a particularly strong year for CES. Our team delivered significant growth across all key metrics with orders growing 38%, revenue up 13%, and operating profit increasing 25%, while operating profit margins expanded 250 basis points to 26.2%. Demand remains robust, driven by global passenger traffic, which is expected to double in 20 years. CES is well-positioned to capture this growth as we continue to service and grow the industry's most extensive installed base, adding to our $154 billion backlog.

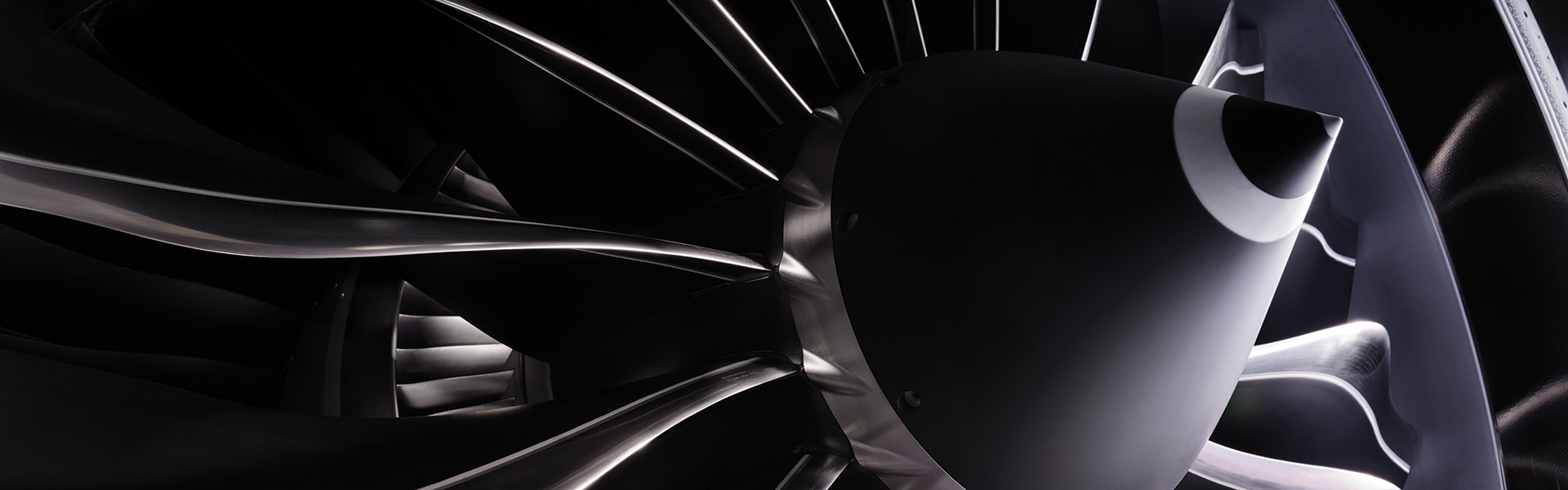

We also celebrated the 50th anniversary of CFM International which is our joint venture with Safran and a leader in narrowbody engines. Building on a long history of innovation, our narrowbody programs—including the CFM56 and the LEAP family of engines—power 75% of narrowbody take-offs. In July, our LEAP program reached a major milestone following the certification of the CFM-powered Airbus A321XLR by the European Union Aviation Safety Agency (EASA) and FAA. Across the A320neo family, LEAP engines have become the preferred choice for more than 100 customers across more than 2,000 Airbus single-aisle aircraft. In December, the FAA and EASA also certified an updated high-pressure turbine hardware durability kit for the LEAP-1A. This certification is a significant milestone in our progress to improve LEAP durability. Combined with the three prior durability enhancements which are currently performing well in the field, we expect this durability kit will result in a more than twofold increase in time on wing and reach parity with CFM56’s performance today, which is widely regarded as the industry benchmark. And it’s easier to produce, supporting our output trajectory going forward.

Complementing our narrowbody business is our widebody portfolio, a significant differentiator for GE Aerospace. Our GEnx engine, the fastest selling widebody engine in our history, continues to capture demand, with recent customer wins. Air New Zealand, ANA, LATAM Airlines, Thai Airways, and British Airways all selected GEnx for future Boeing 787 aircraft. And the GE9X, the largest and most powerful certified commercial engine in the world, is ready to enter into service on the Boeing 777X, with a growing aircraft order book of more than 950 engines to date. In July, we delivered the first GE9X production engine to Boeing and continue to capture customer demand, including a recent order of 16 GE9X engines from Ethiopian Airlines.

Importantly, across CES, we are managing our product lifecycles to enable customer success today and in the future. As our services business continues to grow, we have taken significant actions to increase MRO capacity, including a multi-year $1 billion investment in our internal facilities. We also strengthened our LEAP third-party network with five premier MROs that completed around 10% of total LEAP shop visits in 2024. Additionally, in November, we opened our Services Technology Acceleration Center in Ohio which will enable us to accelerate the deployment of new inspection and repair processes at our MRO shops globally.

Defense & Propulsion Technologies (DPT)

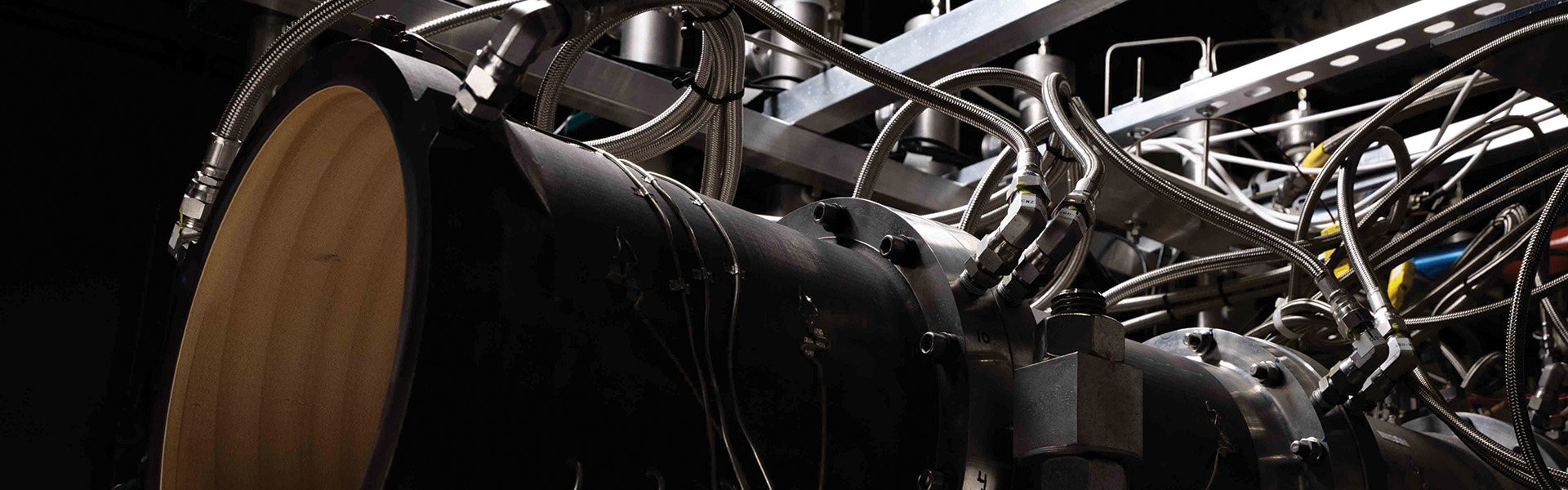

Our DPT reporting segment is composed of Defense & Systems (D&S) and Propulsion & Additive Technologies (P&AT) businesses. Powering two-thirds of all U.S. military combat and helicopter fleets with more than 25,000 engines in our installed base, DPT offers both the leading defense programs of today while developing mission critical technology for the future.

DPT delivered a solid year in 2024, as orders were up 10%, revenue increased 6% and operating profit was up 17% to $1.1 billion, while margins expanded 110 basis points. With a diverse and growing backlog of $18 billion, DPT will continue to drive profitable growth, while investing in the future of combat.

D&S provides the capabilities required to meet the dynamic threat environment. This year we delivered the first two T901 engines for the U.S. Army's Improved Turbine Engine Program for integration and testing on the Sikorsky UH-60 Black Hawk. These deliveries represented a key milestone, ensuring warfighters have the performance, power, and reliability necessary to maintain a significant advantage on the battlefield for decades to come. Additionally, the Polish Ministry of National Defense will add more than 200 T700 engines to power 96 Boeing Apache Guardian helicopters. This paves the way for future partnerships in Poland on other GE Aerospace combat engines.

We’re also investing in the future of combat. The maturity of our digital backbone for the U.S. Army's Future Long-Range Assault Aircraft was critical for Bell to enter the engineering and manufacturing development phase of the program. We completed a successful demonstration of a new, cutting-edge hypersonic dual-mode ramjet, achieving a threefold increase in airflow compared to previously flight-tested hypersonic technology demonstrators.

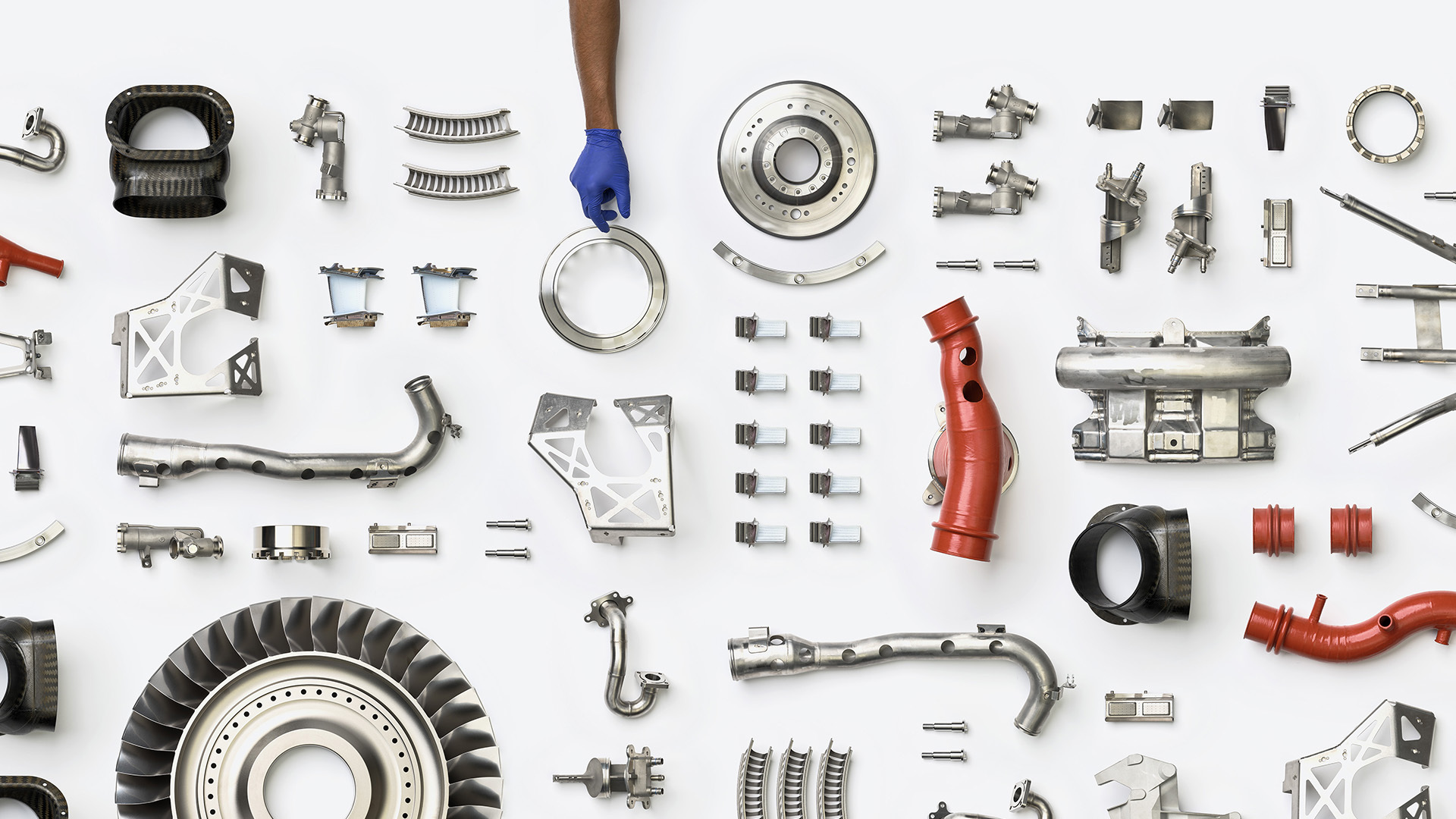

P&AT comprises four businesses—Avio Aero, Unison, Dowty, and Colibrium Additive—that serves GE Aerospace and external customers across Europe and the United States. Avio Aero, our largest and native European company, is a leader in gearboxes, low-pressure turbines, combustors, turboprop engines, and propulsion systems for both civil and military aviation. It is also the partner of choice for the Italian Armed Forces. Our Avio Aero Catalyst engine completed engine-level testing in 2024, with certification expected in first half of 2025. Unison, a key supplier for engine and airframe programs, secured $1.6 billion in new defense contracts in 2024 and successfully launched its BE34U/4 ignition systems into space. With Dowty—a world-leader in electronically controlled, all-composite propeller systems—our public-private partnership depot with the U.S. Air Force became operational and will support its fleet of C-130J aircraft globally. GE Aerospace uses Colibrium Additive’s 3D metal printers to produce several key components for LEAP and GE9X engines.

Achieving sustainable results

In February of 2024 we launched FLIGHT DECK, our proprietary lean operating model, to better serve our customers through a relentless focus on safety, quality, delivery, and cost. FLIGHT DECK is how we translate strategy into operational and financial outcomes as well as strategic breakthroughs, while advancing our culture.

Working alongside our teams around the world to activate FLIGHT DECK in 2024 was energizing.

Take, for example, our teams’ focus on keeping our customers’ fleets flying. They leveraged FLIGHT DECK to expand aftermarket capacity for LEAP to support our growing fleet of 3,300 LEAP-powered aircraft with 10,000 engines in backlog. At our MRO facility in Brazil, we use value stream mapping and problem solving to reduce LEAP test cycle time, a key constraint in shop visit output. We identified waste and improved standard work, reducing lead times there by nearly 50%. Actions like these supported a 40% increase in LEAP aftermarket capacity in 2024. Through our investment and with the help of FLIGHT DECK, our open MRO network will be able to support a higher volume of shop visits for both widebody and narrowbody fleets while reducing turnaround times for customers.

The same meaningful progress can also be seen in how we tackle supply chain constraints head-on to deliver on our new engine backlog. At the start of the year 80% of material shortages were tied to 15 priority suppliers’ sites. Using FLIGHT DECK, we deployed more than 550 of our engineering and supply chain resources into the supply base, and together, we worked to identify labor shortfalls and manufacturing yield issues, alternate material types for raw material shortages, and opportunities to improve flow and lead times. As a result, we increased material input by 26% across these priority supplier sites from the first half of the year to the second half. We also saw a step-change improvement in our priority suppliers meeting their volume commitments from about half in early 2024 to more than 90% today. In turn, this supported significant growth in total engine deliveries across GE Aerospace from the first half to the second half of the year.

We must sustain and improve on this progress in the year ahead. Sustainment takes discipline and rigor. It requires detailed and nuanced work, just the type of problem that FLIGHT DECK is designed to help us solve.

The industry counts on our leadership, and the flying public expects more from us than ever before. We are investing in and progressing the technology building blocks that will define the future of flight.

The CFM Revolutionary Innovation for Sustainable Engines (RISE) technology development and demonstration program with our partner Safran is a great example and has continued to progress. With new technologies like Open Fan engine architecture, we are driving a generational step-change to accelerate the industry’s decarbonization of commercial flight, targeting at least 20% improved fuel efficiency and 20% lower CO2 emissions by the mid-2030s compared to today’s commercial engines.

Since the launch of the RISE program, more than 250 tests have been completed, including our first test of next-generation high-pressure turbine air foils for the compact core. In 2024, we expanded our partnership with the U.S. Department of Energy to use supercomputing for modeling Open Fan aircraft integration with Boeing, NASA, and Oak Ridge National Laboratory. Additionally, CFM and Airbus teams continue to work together on engine and aircraft design integration in preparation for an Open Fan Flight Test Demonstrator this decade. As part of the RISE program and in partnership with NASA, we have also completed initial testing of electric motor/generators and power electronics for the HyTEC Turbofan Engine Power Extraction Demonstration, one of several efforts underway to mature technologies for more electric aircraft engines. The ability to reduce emissions through technological innovation is critical to staying competitive. I am confident we are up to that challenge, and many others.

Beyond RISE, our engineering team and Aerospace Research Center successfully demonstrated a new hybrid electric propulsion system for the U.S. Army that was rated at one megawatt—a meaningful increase in power generation, enabling us to advance hybrid electric propulsion applications. Our digital technologies team launched the company’s first generative AI platform which we call Wingmate. And our Edison Works team continues to focus on developing and delivering the advanced technologies for the future of combat including advanced materials, hypersonics, small engines for unmanned applications, and next-generation adaptive cycle engines.

Inventing the future of flight has always motivated GE Aerospace, from the early days more than 100 years ago to our research labs of today.

One team

During a year of so many historic firsts for GE Aerospace, it would be easy and understandable to point to one of our moments in the spotlight as the highlight of the year. But in fact, GE Aerospace shined brightest during one of our darkest hours.

In October, our GE Aerospace team and community in Asheville, NC were deeply impacted by Hurricane Helene. The destruction left behind and the traumatic loss that so many experienced was unfathomable. But through the darkness, it was remarkable to see the spirit amongst the GE Aerospace team. Even those who have suffered loss were selflessly looking to help others.

Matthew Griggs, GE Aerospace’s Global Facilities Manager, and his team worked around the clock to coordinate supply runs and health-related support for our employees—everything from water, meals, and fuel to trash disposal, portable showers, washers and dryers, and generators. When I asked Matthew how he and the team were doing through all this, his reply was simple, “This is what we do for each other.” Working as one team with one mission, it was respect for people in action. It was GE Aerospace at its finest.

Matthew is an example of what makes the people at GE Aerospace so special. Their work isn’t just a job. It is their passion and purpose. Because of them, we made history this year. And because of them, it's only just the beginning.

Thank you for your investment and belief in us. One year in, we are excited for what’s ahead and look forward to climbing to new heights together.

* Non-GAAP Financial Measure

"When it comes to safety, we never compete. It is a team sport and an industry-wide effort."

GE Aerospace Annual Report 2024