Our storied history in

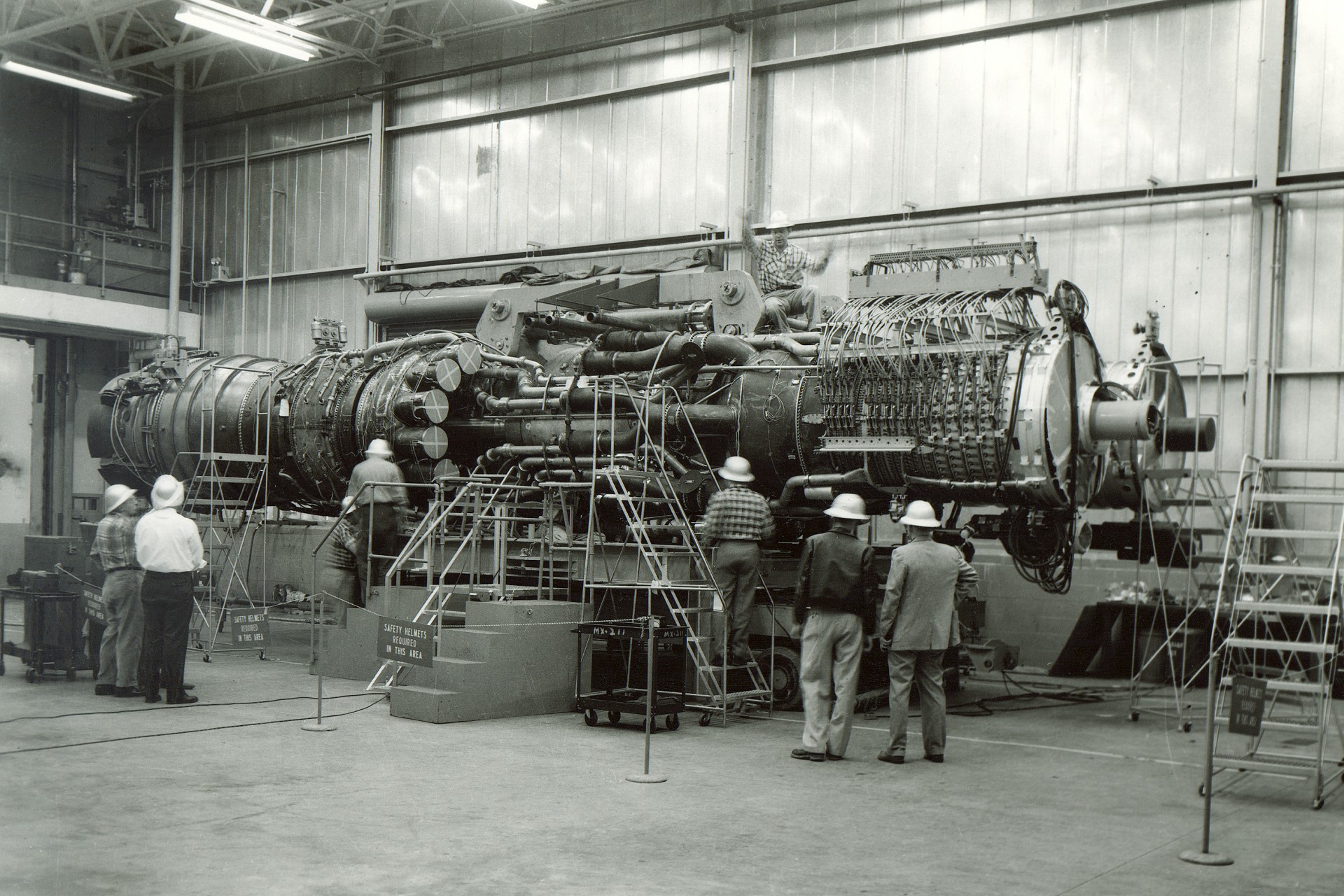

GE Aerospace's journey in Asia Pacific began with a deep and enduring partnership with South Korea when the F-86 fighter jet powered by the J47 engine was first introduced in the nation in the mid 1950s . This milestone marked the start of a shared vision for technological advancement that would shape the future of aerospace in the region. Today, GE Aerospace is a proud partner of South Korea’s national defense.

GE Aerospace expanded its reach in Asia Pacific in December 1979, by establishing a presence in Singapore. The Singapore government, eager to attract high-technology investments, played a pivotal role in this expansion. In 1981, the GE Aviation Service Operations (GEASO) office was officially launched, recognizing Singapore’s potential as a leader in aerospace innovation. This facility, dedicated to repairing and refurbishing key aircraft engine components, quickly became a vital part of the region’s aerospace infrastructure, allowing GE Aerospace to serve customers across Asia Pacific.

Strategic alliances and expansion

In 1996, GE Aerospace's pioneering spirit led to a partnership with Teleflex Inc., resulting in the establishment of Airfoil Technologies International (ATI) in Singapore. This alliance created Asia Pacific’s first one-stop repair facility for high-pressure compressor airfoils, revolutionizing the industry with its ability to repair 1.2 million blades annually.

GE Aerospace continued its expansion with the launch of GE Aerospace Engine Services Malaysia (GEESM) in 1997. This Maintenance, Repair, and Overhaul (MRO) hub for engines quickly became a key part of GE Aerospace’s global operations. It currently employs more than 720 local professionals and provides MRO services to more than 50 airlines worldwide.

The new millennium brought further growth as GE Aerospace set up an On Wing Support (OWS) facility at Gimpo Airport in South Korea. This was part of a strategy to provide 24/7 Aircraft on Ground (AOG) support through a global network of OWS sites, ensuring timely service wherever needed. Around the same time, GE Aerospace began offering Total Logistics Support (TLS) services to T700 engines, powering the Australian Defense Force’s MH-60R helicopters. Building on this success, GE Aerospace expanded its services to commercial aircraft, powering regional carriers like Qantas, Jetstar, Air New Zealand, and Virgin Australia.

Global manufacturing, repair, and service capabilities

GE Aerospace’s momentum continued into the late 2000s with strategic investments to enhance capabilities. In 2008, a $30 million expansion of the GEASO facility in Singapore added production space and new repair capabilities for engines like those powering Boeing’s 787 Dreamliner and 747-8 aircraft. This growth solidified Singapore as a key hub for GE Aerospace in Asia Pacific.

In 2009, GE Aerospace fully acquired ATI-Singapore, consolidating operations to strengthen its global repair and service capabilities. In 2013, the company enhanced its OWS capabilities in South Korea by expanding the Seoul OWS facility, allowing for expanded engine servicing. This growth aligned with GE Aerospace’s strategy to continually enhance its service offerings in key markets.

In 2016, GE Aerospace merged its Singapore repair facilities, GEASO and GE-ATI, into a single entity – GE Aerospace Engine Services Singapore – streamlining operations to better serve customers. That same year, GE Aerospace announced a $110 million investment in its Singapore operations, creating a Lean Lab for Advanced Manufacturing, an Asia Pacific Center of Excellence for product repair, and an Automation & Robotics Center of Excellence.

In 2018, GE Aerospace partnered with the Singapore Economic Development Board to launch an Additive Manufacturing Center at Seletar Aerospace Park, advancing 3D printing technology for jet engine airfoil component repairs. By 2021, the facility became the first MRO site globally to pioneer additive repairs for these components, handling over 60% of GE Aerospace’s global repair volume. In Malaysia, GE Aerospace also expanded its MRO facility with a major US$80 million investment, cementing its role as a critical MRO hub for Malaysia’s aviation industry.

the legacy of

Advancing aerospace innovation in Asia Pacific

In 2022, GE Aerospace introduced its 360 Foam Wash system to Japan Airlines, making it the first CF34 operator to adopt this innovative engine-cleaning technology. Later that year, GE Aerospace opened an $8 million Asia Pacific Service Center in Brisbane, further enhancing MRO capabilities for the region. With this new center, the largest Systems Center in Asia Pacific, GE Aerospace is well placed to meet the evolving needs of its regional clients.

Supported by the Singapore Economic Development Board, the company invested $11 million to build a Smart Factory at its Singapore facility in 2024. This cutting-edge factory will revolutionize engine repair processes and advance workforce skills, ensuring GE Aerospace remains at the forefront of aviation technology.

Today, GE Aerospace's strong presence in Asia Pacific includes key facilities in Singapore, Malaysia, South Korea, and Australia, supporting more than 110 customers. Committed to innovation, we will continue to collaborate locally to meet the region’s evolving aviation needs and shape the future of flight.