GE90 Engine

A giant in

the industry

Launched in 1990, the GE90 engine is GE Aerospace’s first engine in the 100,000-pound thrust class and became the most technologically advanced commercial turbofan engine in 25 years.

Groundbreaking firsts

1

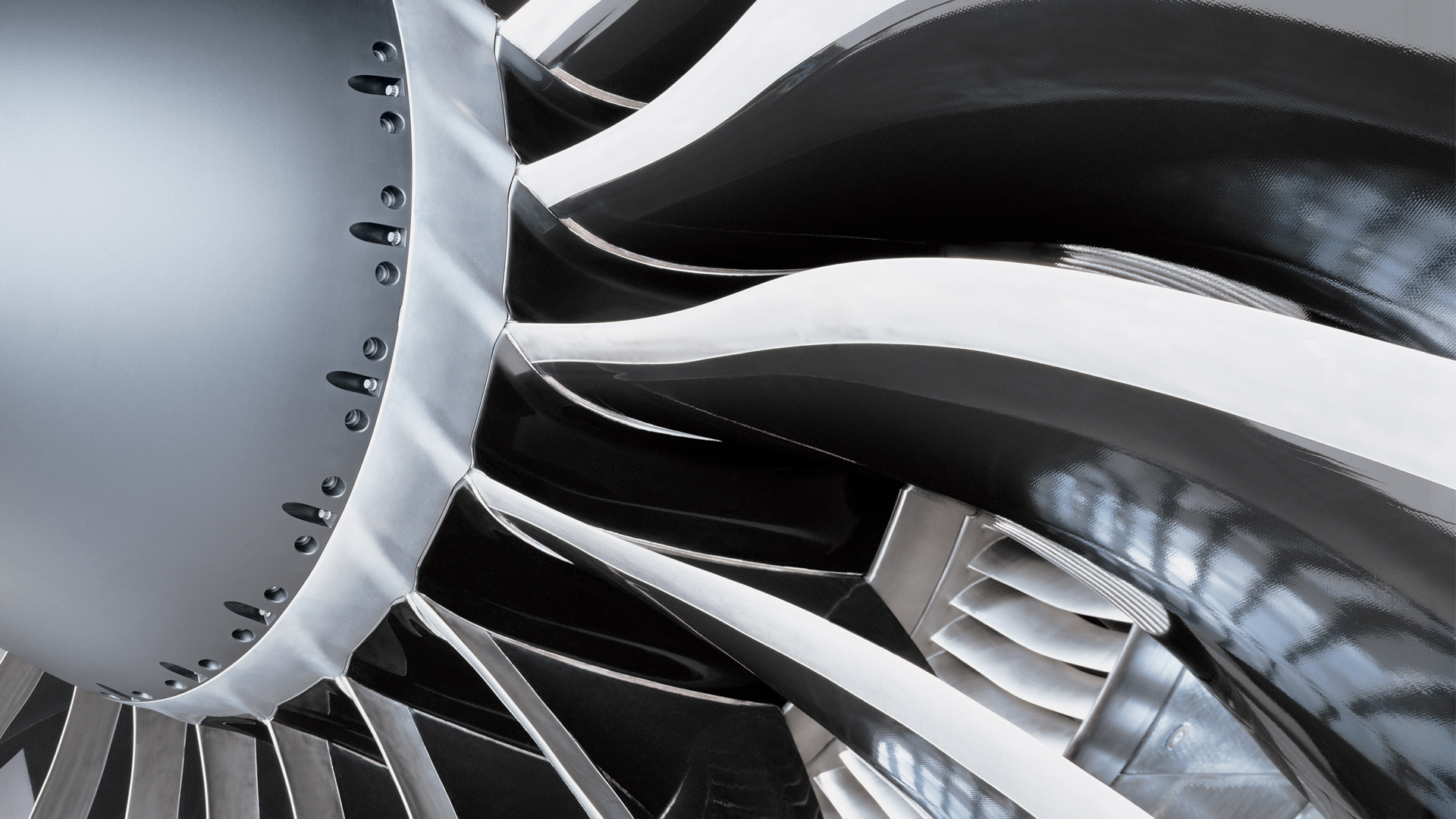

STFirst composite fan blade

Commercial engine with composite fan blades for double the strength at one-third the weight of traditional titanium fan blades – now a hallmark on GE Aerospace’s widebody engines

127

KFirst to reach 127K lbs. of thrust

Engine reached 127,900 Ibs of thrust, a world record (since broken by the GE9X engine at 134,300 lbs. during certification testing)

FOD

FreeFirst FOD-free core

Engine incorporated inward opening variable bleed valve doors for a FOD (foreign object debris)-free core

1

STFirst additive part

Engine received FAA approval for additive manufactured compressor sensor

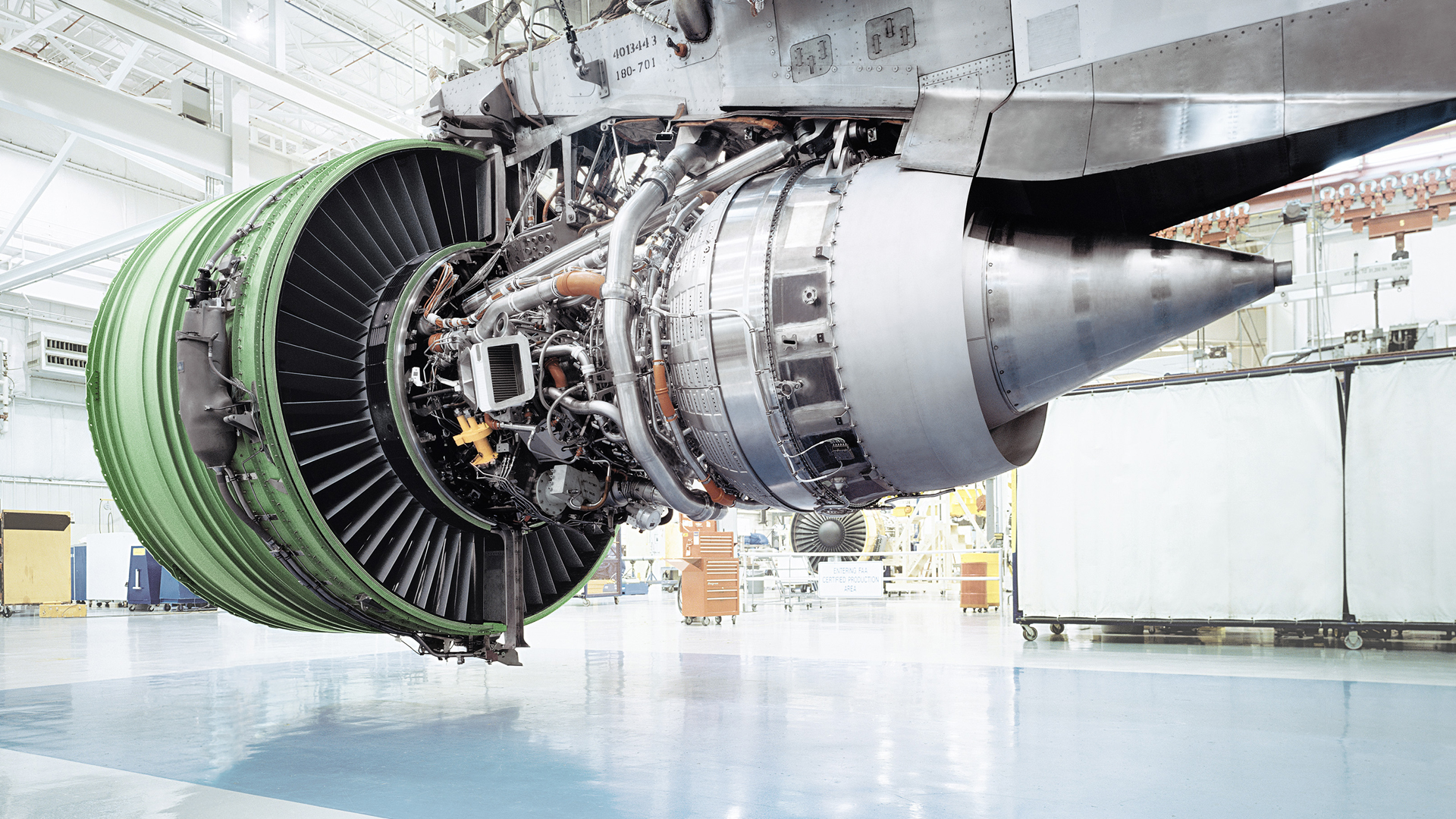

The GE90 engine

Powering the twin-engine Boeing 777 aircraft, the GE90 engine combined record thrust and high reliability with lower noise, emissions, and fuel consumption to become an iconic jet engine recognized worldwide for its size and innovations.

Maturation at its finest

GE Aerospace has continued to invest and improve the engine. GE Aerospace engineers have enhanced the GE90-115B engine’s compressor, combustor, and high- and low-pressure turbine components to reduce weight, improve fuel efficiency, and enhance durability.

- 3.6% reduction in fuel burn from initial launch specification

- 60% improvement in time on wing

- World-class 99.98% reliability rate

Service anywhere

you need care

you need care

With more than 2,800 GE90 engines delivered around the world, GE Aerospace and its global network of maintenance, repair, and overhaul (MRO) providers are anywhere that our customers need support. Through GE Aerospace’s TrueChoice engine services suite, GE90 operators have access to MRO options that can optimize the engine to meet a desired life cycle with targeted workscopes, optimizing hardware utilization and minimizing cost of ownership.

GE90-94B engine

Rated at 94,000 lbs. of thrust, the GE90-94B engine builds on the proven success of the early GE90 engine models to power the Boeing 777-200 and 777-300 aircraft.

GE90-115B engine

After being selected by Boeing to develop an engine with 110,000 to 115,000 lbs. of thrust, GE Aerospace delivered the GE90-115B engine, which now powers the longer-range Boeing 777-200LR, 777-300ER, and 777 Freighter aircraft.

GE90 Engine Model Comparison

PHYSICAL INFORMATION

-94B

-115B

Fan/Compressor Stages

1/3/10

1/4/9

Low-Pressure Turbine / High-Pressure Turbine

6/2

6/2

Maximum Diameter (Inches)

134

135

Length (Inches)

287

287

POWER SPECIFICATIONS

-94B

-115B

Max Power at Sea Level

93,700

115,300

Overall Pressure Ratio at Max Power

40

42