GE Aerospace

ARPA-E programs

GE Aerospace is proud to partner with

ARPA-E to advance a safer, more efficient

future of flight.

ARPA-E Energy Innovation

At any given moment in time, more than 950,000 passengers are being transported around the world with GE Aerospace engines under wing. We are committed for the long-haul to investing in America’s energy leadership for the future of flight across our nation and around the world.

The below programs highlight key projects with ARPA-E to advance efficiency in air travel. Read on for additional details about what we’re working on.

- FLYCLEEN

- eFLITES

- MAAGIC

- EPIC-TRAILS

Advancing flight for future generations

3

out of every 4

Commercial flights are on GE Aerospace-powered aircraft.

If you flew in for the Conference, it's very likely your plane was powered by one of our engines. GE Aerospace is one of the world’s leading jet engine manufacturers, with approximately 49,000 commercial and 29,000 military aircraft engines.

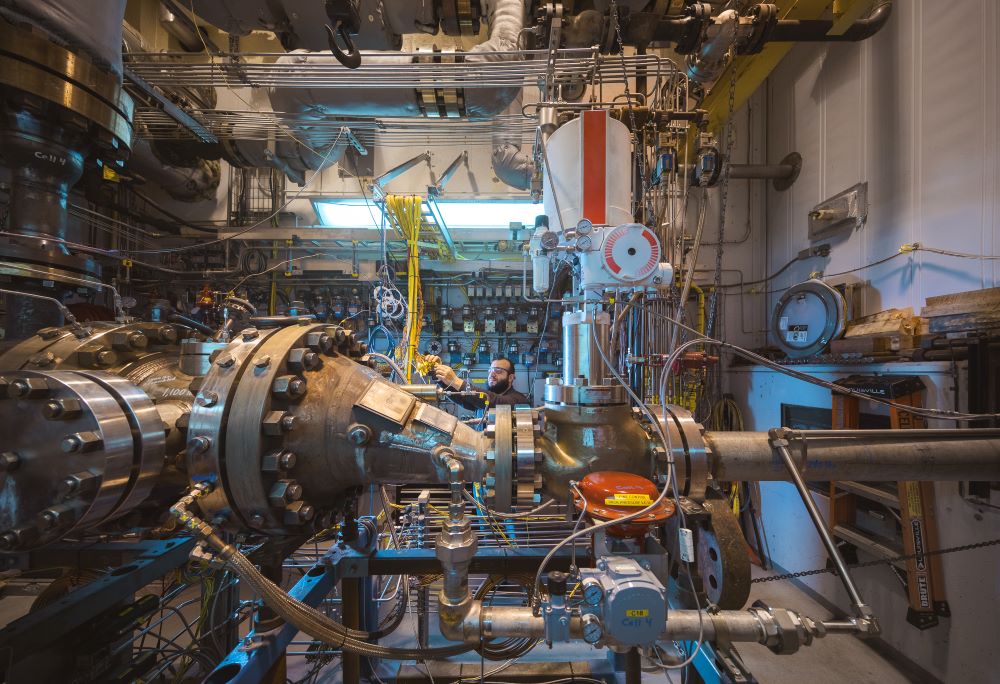

FLYCLEEN

One of the fundamental keys to hybrid electric flight is building a power generation system. GE Aerospace researchers are now in Phase 2 of their REEACH program project with ARPA-E to build and demonstrate a 25kW power generation subsystem integrating 5-kWe solid oxide fuel cell stacks with a Sustainable Aviation Fuel (SAF) or Hydrogen Fuel powered gas turbine combustor for hybrid electric propulsion. The use of fuel cells could vastly improve the efficiency of converting the chemical energy from fuel into electric power.

- PI: John Hong, Senior Engineer, Combustion, GE Aerospace Research

- ARPA-E REEACH Program

eFLITES

GE Aerospace's efforts to demonstrate a hybrid electric powertrain system for commercial aircraft is gaining altitude through its ongoing work ARPA-E’s ASCEND program to support GE Aerospace's Electric Flightworthy Lightweight Integrated Thermally Enhanced Powertrain System (eFLITES) project. Now in Phase 2 of their program, GE Aerospace researchers are preparing to demonstrate the next version of a powertrain system, which represents the next key project milestone toward a full-scale 2MW powertrain system.

- PI: John Yagielski, Senior Principal Engineer, Electric Machines, GE Aerospace Research

- ARPA-E ASCEND Program

MAAGIC

One of the principal challenges to enable commercial scale passenger hybrid electric flight is developing insulation technologies that can effectively manage higher voltage levels of electricity required to support both the propulsion and electrical systems onboard the aircraft. GE Aerospace researchers are working their MAAGIC (Megawatt Any-Altitude Gas Insulated Cable) with ARPA-E to develop more efficient, lightweight electrical cables that deliver the optimal insulation solutions.

- PI: Han Xiong, Senior Engineer, Electric Machines, GE Aerospace Research

- ARPA-E REEACH Program

EPIC-TRAILS

GE Aerospace researchers are working in “the cloud” to understand the impact of aircraft-formed induced clouds called contrails in the sky. In collaboration with Southwest Airlines, the team is working on a $2.2 million project through a new program from ARPA-E’s called Predictive Real-time Emissions Technologies Reducing Aircraft Induced Lines in the Sky (PRE-TRAILS). The team will be developing in-flight digital tools to gain a deeper insight and understanding on the impact of contrails to help enable a more efficient future of flight.

- PI: Saikat Ray Majumder, Senior Scientist, Statistical Signal Processing, GE Aerospace Research

- ARPA-E ET-PRETRAILS Program

*The CFM LEAP is produced by CFM International, a 50/50 joint company between GE Aerospace and Safran Aircraft Engines.