The 15 Top Tech Stories That Powered GE Aerospace Forward in 2024

December 16, 2024 | by Christine Gibson

Standing on the cusp of a new era of growth, GE Aerospace’s priorities remain as clear as ever: a commitment to inventing the future of flight, lifting people up, and bringing them home safely, underpinned by a dedication to safety, quality, delivery, and cost. As the company finishes its first calendar year as a stand-alone public company, here’s a look back at the stories that charted its progress in 2024.

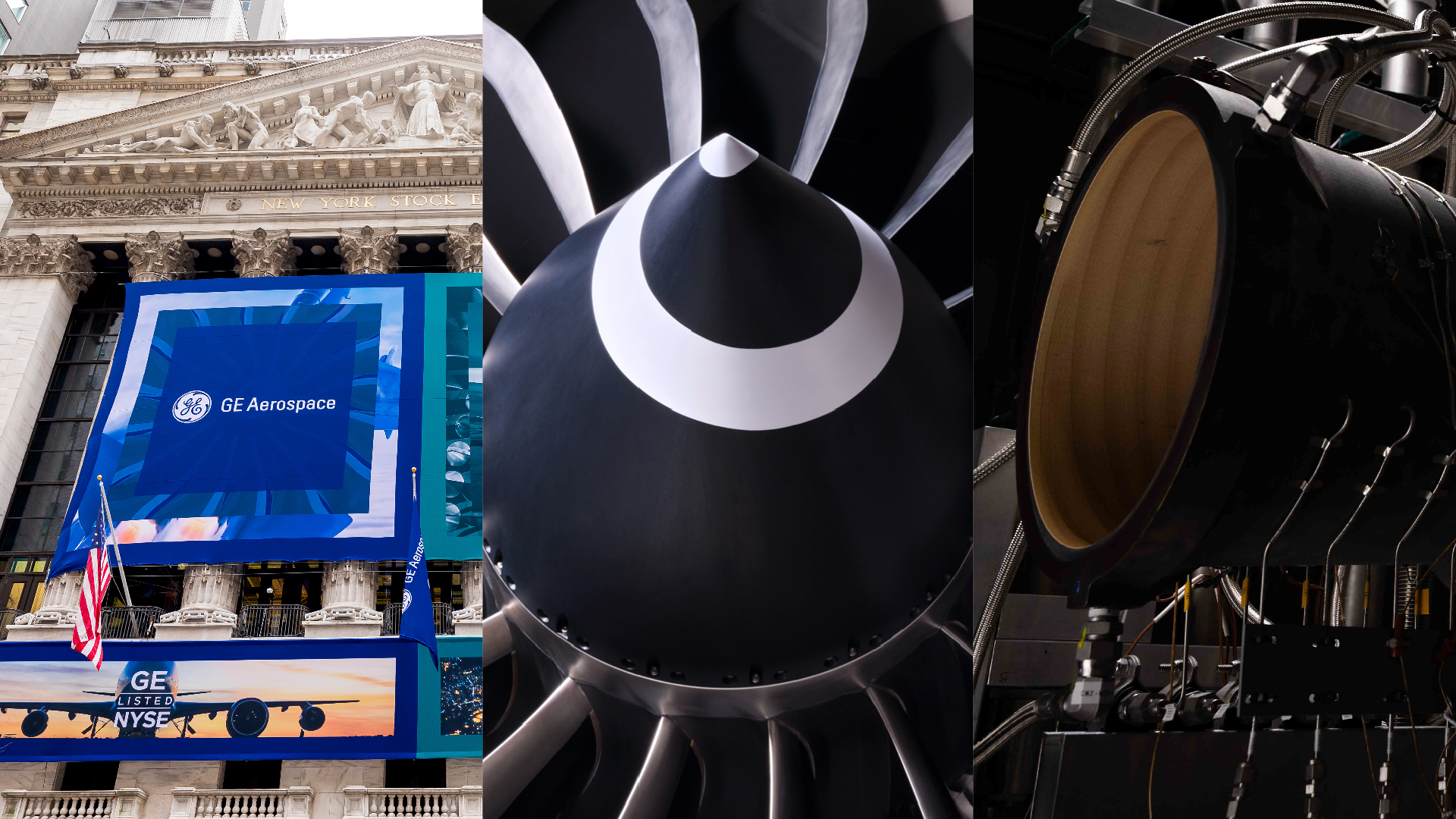

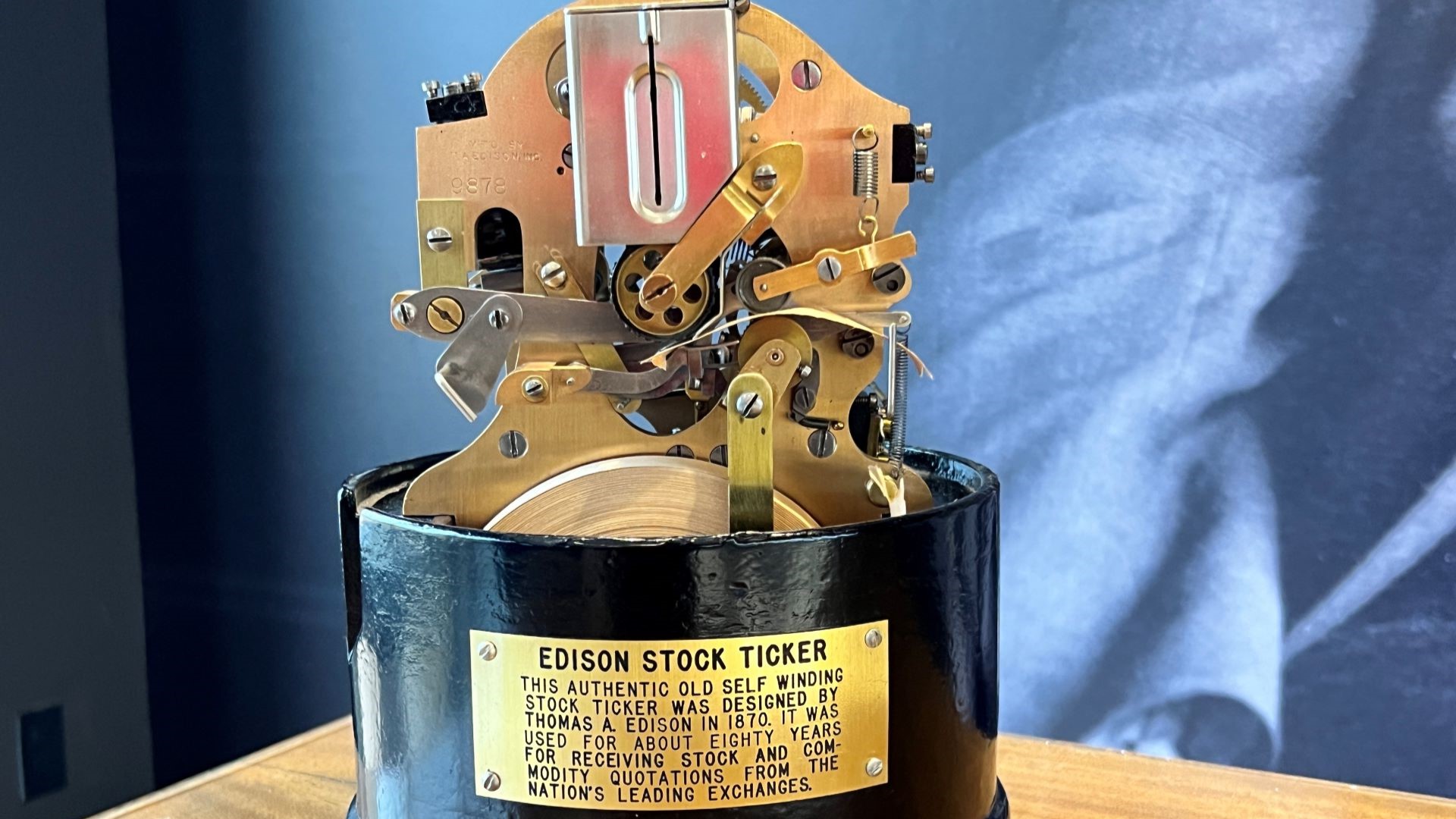

1. We Are Go: GE Aerospace Builds on Legacy of Invention

On April 2, 2024, GE Aerospace launched as a standalone, public company. It was the culmination of a multi-year transformation. After more than a century of technological advancements, GE Aerospace is moving forward with renewed focus on the next age of innovation. Our report reviews the company’s legacy and the initiatives that will continue to shape the future of flight.

2. GE Aerospace Forms Coalition with Industry Leaders to Strengthen Aviation Supply Chain Integrity

In February, GE Aerospace became a founding member of a new Aviation Supply Chain Integrity Coalition, whose aim is to help prevent unauthorized parts from entering the aviation supply chain. This was a response to a rogue actor in 2023 selling engine parts with forged documents, an event that was promptly dealt with, but, said coalition co-chair Robert Sumwalt, “more is needed to stop anyone who tries to take a shortcut in the future.”

To help meet rising demand, GE Aerospace invested $650 million in its manufacturing sites and supply chain this year. To take one example, the company’s plant in Durham, North Carolina, received $7.6 million to increase production of some of the world’s most popular turbofans, including the GE9X, GE90, GEnx, CF6, CF34, CFM LEAP,* and CFM56* engines. Learn how the plant’s pioneering, worker-led approach to management has sped up the workflow and reduced errors.

Lean, a management philosophy focused on eliminating waste, was originally developed to streamline manufacturing processes. Now, teams at GE Aerospace have translated those concepts to root out bottlenecks in all kinds of processes through FLIGHT DECK, the company’s proprietary lean operating system. Read how the Celma maintenance, repair, and overhaul (MRO) shop in Brazil used lean techniques to shave nearly two weeks off performance restoration shop visits.

Building on the more than 100-year legacy of the GE Foundation, the GE Aerospace Foundation officially launched in May with more than $20 million in commitments to the Next Engineers Engineering Academy, workforce development programs, and disaster relief. Read more about how the foundation is making a positive impact in communities around the world.

Frontier, a U.S. government supercomputer billions of times quicker than the human mind, is accelerating the development of ultra-efficient engine technologies as part of the CFM RISE* program. GE Aerospace engineers are using Frontier to model how fan blades will perform in simulated flight conditions, yielding information that would otherwise take years to gather. Read more about the team’s groundbreaking efforts.

With more than 11 million flight hours under its wing, the F110 engine powers fighters and advanced aircraft for the U.S. military and 16 allied nations. Nearly four decades after the F110 engine entered service, production levels are poised to reach new heights, thanks to its combat-proven track record and performance- and reliability-enhancing upgrades. Learn more here.

8. GE Aerospace Successfully Develops and Tests New Hypersonic Dual-Mode Ramjet

Just 11 months after design work began, GE Aerospace demonstrated a new hypersonic dual-mode ramjet. With a threefold increase in airflow over previous demonstrators, the cutting-edge technology could enable high-speed flight and longer range for several multi-mission aircraft. Read more.

9. Ain’t No Stopping Us Now: CFM’s RISE Program Gains Momentum

This past summer, CFM International announced that its Revolutionary Innovation for Sustainable Engines (RISE)* technology demonstration program had completed more than 250 tests on its path toward development of a full-scale Open Fan engine. Earlier in the spring, Arjan Hegeman, general manager of advanced technology for GE Aerospace, signaled that the program was advancing in leaps and bounds. “It’s full speed ahead for the RISE program in 2024,” he said. “It’s a period of innovation unlike anything GE Aerospace has seen before.”

10. GE Aerospace Commits $1 Billion to Its MRO Network to Support Unprecedented Aftermarket Ramp-Up

Every two seconds, an airliner powered by GE Aerospace or its partners takes off somewhere in the world. To keep these engines in top shape, the company is investing $1 billion in its global MRO network over the next five years, supporting a higher volume of shop visits and reducing turnaround times. Find out more.

11. White Light Inspection Robots Bring New Efficiency and More Consistency to the MRO Shop

When it opened this fall, GE Aerospace’s Services Technology Acceleration Center became the company’s first MRO site to deploy AI-guided “white light robots.” Learn how these optical scanners are using AI to inspect complex parts faster and more accurately.

12. GE Aerospace and Safran Aircraft Engines Celebrate 50th Anniversary of CFM International

In the five decades since GE Aerospace and Safran Aircraft Engines joined forces to create CFM International,* the venture has delivered more than 42,000 engines to hundreds of commercial and military operators around the world — evidence of the remarkable innovation at the heart of such engines as the CFM56 and CFM LEAP, as well as the company’s development work on the RISE program. Here’s our look back at the important milestones that helped make CFM International the most prolific jet propulsion company in aviation history.

13. Reimagining Flight: GE Aerospace Propulsion Hall of Fame Inducts Five New Members

In October, GE Aerospace inducted five new members into its Propulsion Hall of Fame, which honors leaders who have pushed the boundaries of flight and driven generational advancement in the broader aerospace industry. Learn about the honorees’ transformative work here.

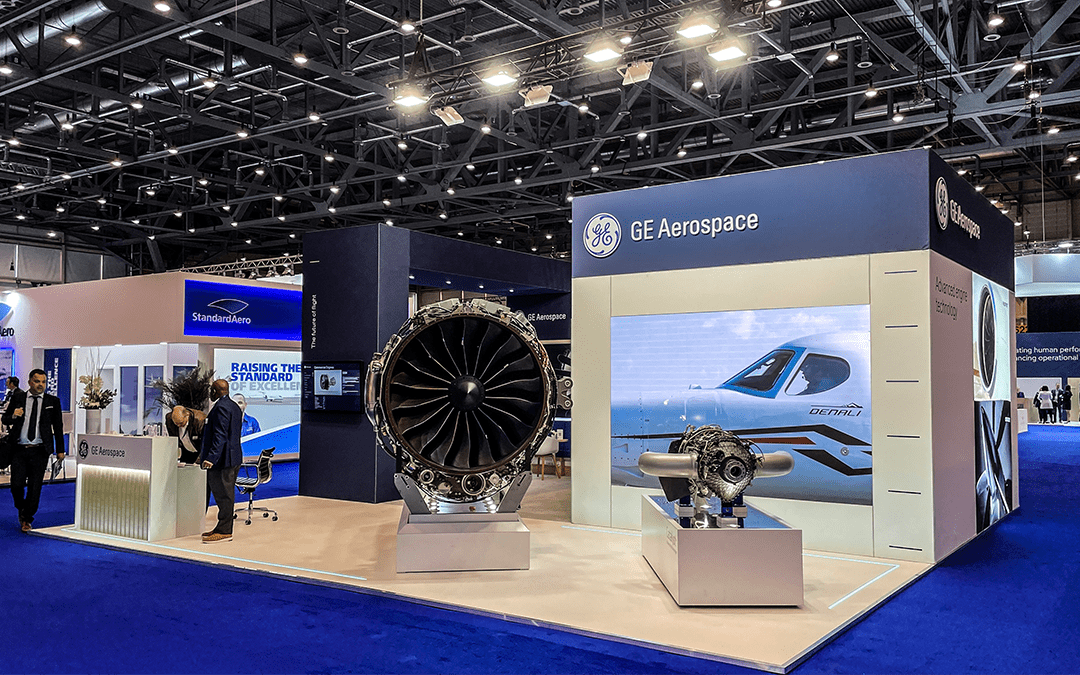

14. CFM LEAP Engine Goes on Tour to Thank Employees (and Attract Some New Ones)

To celebrate CFM International’s 50th anniversary, the company sent a CFM LEAP* engine on a tour of colleges and GE Aerospace sites around the eastern U.S. Mounted on the bed of an 18-wheeler, the attention-grabbing engine served as a recruiting tool for future engineers and gave employees a rare chance to get an up-close look at the finished product. Read more.

After just 12 years in service in the region, the GEnx engine is at the center of South Asian aviation’s rapid growth, powering long-haul flights for Air India, Vistara, and Biman Bangladesh. Read how a combination of redesigned parts and new technology have helped the GEnx withstand heat and dust to spend four times longer on wing than competitors’ engines.

*CFM LEAP and CFM56 engines are products of CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines. RISE is a CFM technology demonstration program.