Smooth Takeoff: GE Aerospace’s First Year Flying Solo Has Reinforced Its Special Sense of Purpose, Explains Culp

April 01, 2025 | by Chris Noon

GE Aerospace, which marks its first anniversary as a standalone public company on April 2, is soaring to new heights. The company had a “monumental” financial performance in 2024, which included $1.7 billion of profit growth and $1.3 billion of free cash flow growth. In this interview, Chairman and CEO Larry Culp explains why GE Aerospace’s success is about more than just the numbers, and shares insights into the company’s journey, its unique culture of innovation, and his vision for the future of flight.

GE Aerospace Reports: Larry, congratulations on GE Aerospace’s first year as a standalone public company. How would you sum up the past 12 months?

Culp: Thank you. It’s been an incredible journey. I couldn’t be prouder of what our team has accomplished together with our customers and industry partners — and we’re only just getting started. Our launch as a standalone public company was the springboard for a monumental first year for GE Aerospace. Since this time last year we have increased our market cap by approximately $65 billion while delivering strong financial results in 2024, with total orders up 32% to $50.3 billion, revenue up 9% to $38.7 billion, and profit up 27% to $7.6 billion. And along the way we’ve achieved significant milestones, including U.S. Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) certification for the updated high-pressure turbine (HPT) hardware for our CFM LEAP engine program* — extending time on wing and delivering more value for our customers.

But there’s a story beyond the numbers and business achievements, and that’s the passion and commitment of our people. Every day, our teams around the world are living our purpose to invent the future of flight, lift people up, and bring them home safely. Using FLIGHT DECK, our proprietary lean operating model, we are focused on driving continuous improvement. It’s about SQDC — safety, quality, delivery, and cost — always in that order, with safety as our top priority. I’m proud of the progress we have made and even more excited for the opportunities ahead of us.

You wrote about feeling a special sense of purpose on the podium of the New York Stock Exchange (NYSE). A year on, how do you remember the company’s launch day?

That day was more than 100 years in the making. Filled with pride in GE’s history and excitement for our future, GE Aerospace’s launch day was all about the team — our 53,000 employees around the world who are inventing the future of flight for generations to follow. I was honored to share the podium with several of those employees for the NYSE opening bell that morning, and then flew straight to our headquarters in Evendale, Ohio, to continue the celebrations. We were joined virtually by our global teammates around the world, from Lynn, Massachusetts, to Bengaluru, India. I will never forget the sense of pride and purpose I felt across the team that day, and still feel to this day.

And now, a year later, how are you and the GE Aerospace team marking the occasion?

Following a year of so many historic moments for the company, perhaps what stands out most is the way our GE Aerospace team shined brightest in one of our darkest hours: Hurricane Helene and the devastation it left behind in western North Carolina, including for our employees and their families in Asheville. Through the darkness, it was remarkable to see our team members and the impacted community come together to support one another — providing everything from food and water to portable showers and generators. Even those who had suffered loss were selflessly looking to help others. They represented GE Aerospace at its finest.

With the spirit of Asheville in mind, we are proud to celebrate our first anniversary as a standalone business by giving back to the communities where we live and work. During our first-ever Volunteer Week, taking place March 31 through April 6, our teams around the world are participating in more than 80 volunteer activities with local food banks, schools, veterans’ centers, and other organizations across nearly 40 of our global facilities. This builds on more than 30,000 volunteer hours from our employees in 2024, in addition to more than $21.5 million in philanthropic contributions from our company, employees, and the GE Aerospace Foundation last year. A lot to feel good about and a great way to mark our anniversary.

You talked earlier about safety as GE Aerospace’s top priority, certainly a major focus for the industry over the past year. How do you maintain GE Aerospace’s safety culture?

There are approximately 950,000 people in the sky at any given moment with technology made by GE Aerospace and our joint venture partners under wing. We think about that every single day at GE Aerospace. We have a tremendous responsibility to our customers and the flying public that each member of the team takes very seriously. Each of us owns safety — at all levels of the organization, from the shop floor to engineering and sourcing to the leadership team. We operationalize safety through our Safety Management System and Quality Management System — enabling us to identify safety risks and actively work to mitigate those risks through root cause and problem-solving. We often say in this industry that when it comes to safety, we never compete. Safety is a team sport and an industry-wide effort. It takes all of us working together and learning from one another.

In addition to using FLIGHT DECK to improve your own operations, you are also using it with your customers and suppliers. Can you tell us more about that?

A great example of FLIGHT DECK in action is the work we’ve done with our suppliers. At the start of 2024, we realized 80% of material shortages were tied to 15 priority supplier sites. Using FLIGHT DECK, we brought their best people together with ours — deploying more than 550 of our engineering and supply chain resources into the supply base to problem-solve together. As a result, we increased material input by 26% across these priority supplier sites from the first half of the year to the second half, and saw a step-change improvement in our priority suppliers meeting their volume commitments from about half in early 2024 to more than 90% today. Ultimately, this has supported significant growth in total engine deliveries across GE Aerospace in support of our customers. While we still have more work to do, this is the power of FLIGHT DECK.

Shifting to innovation, what progress has GE Aerospace made in advancing aviation technology over the past 12 months?

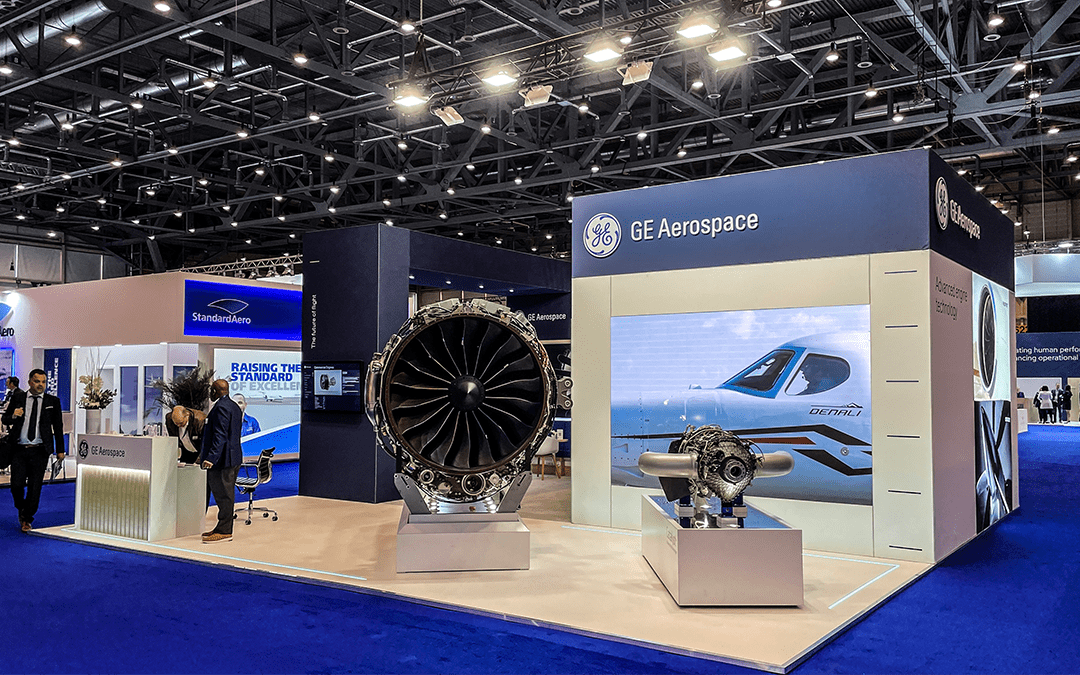

With our roots going back to Thomas Edison, innovation has always been core to GE Aerospace’s DNA. We constantly push the boundaries of what’s possible for the future of flight — and we’ll continue to do so with safety at the forefront. In addition to the HPT certification I mentioned earlier for our CFM International LEAP engine program, which continues to set new standards for fuel efficiency and reliability in narrowbody aircraft, another great example of our innovative spirit is the Catalyst engine, which also recently received FAA certification. This is the first clean-sheet turboprop engine to hit the market in over 50 years, showcasing our commitment to developing next-generation propulsion systems.

In defense, we achieved successful ramjet ground-level tests that have advanced the goal of hyper-efficient, high-speed, and long-range hypersonic flights, and our engineers are preparing to prove their breakthrough technologies in the skies. The T901 engine has successfully completed initial ground runs on a Black Hawk helicopter, marking a significant step forward in the U.S. Army’s Improved Turbine Engine Program.

What about investing in the business? Will the company continue its strong research and development (R&D) commitment?

Absolutely. In 2024, we spent approximately $2.7 billion in R&D (including customer and partner funding), driving breakthroughs in Open Fan engine architecture through the CFM RISE (Revolutionary Innovation for Sustainable Engines) program, as well as hybrid electric propulsion, hypersonics, and next-generation adaptive cycle engines, among others.

We’re also making substantial efforts to expand and modernize our manufacturing and maintenance capabilities to better serve our customers and drive innovation. We invested $550 million in our U.S. manufacturing facilities and supply chain last year, and we just announced a $1 billion investment for 2025. We also launched a $1 billion investment in our maintenance, repair, and overhaul (MRO) facilities and capabilities through 2029.

Let’s look to the future. What’s your outlook for the commercial aviation market, and how is GE Aerospace positioned to capitalize on it?

We’re seeing strong recovery and growth in commercial aviation, particularly in the narrowbody segment. Our LEAP engine is uniquely set to capitalize on this trend. We have a substantial backlog and are ramping up production to meet demand. In the widebody market, our GE9X engine for the Boeing 777X is progressing well, and we’re excited about its potential. Overall, we’re well positioned across all segments of commercial aviation, from regional jets to the largest widebodies.

How is GE Aerospace addressing the increasing focus on new technology innovation to drive greater efficiency in aviation?

Our long-term focus on innovation is a key differentiator, and we’ve always prioritized better fuel efficiency in our engines to meet our customers’ needs. Our engineering teams around the world have advanced new technologies to support current engine programs and continue to look at how we can improve our product performance and maintenance. A great example of this is the LEAP engine, which is 15% more fuel efficient than the engine it replaces and for which we recently introduced new high-pressure turbine (HPT) hardware to further improve durability. But we’re not stopping there. As we look to the future of flight, we’re also investing heavily in the development of new technologies. With our CFM RISE program, we’re maturing and testing a suite of new engine technologies including Open Fan, compact engine cores, and hybrid electric systems with the goal of creating a future engine that has more than 20% better fuel efficiency than engines today.

Finally, have you got a message for GE Aerospace employees and business partners as you look ahead?

To our employees, thank you. Your dedication, innovation, and commitment to our purpose are what make GE Aerospace a leader in our industry. To our partners: We’re excited about the future and confident in our ability to deliver long-term value. We have a strong foundation, a clear strategy, and the right team to execute it. As we continue to invent the future of flight, we remain focused on FLIGHT DECK, serving our customers, and driving innovation. Together, we’re not just shaping the future of aviation — we’re lifting the world to new heights.

*CFM LEAP engines are a product of CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.