This is Much More Than a Service Recovery, It’s an Opportunity

April 26, 2022 | by Russell Stokes

Russell Stokes is Senior Vice President, Commercial Engines for GE Aviation. He leads the services business within GE Aviation’s $15 billion Commercial Engine & Service franchise and oversees a team of 7,000 employees responsible for

Russell Stokes is Senior Vice President, Commercial Engines for GE Aviation. He leads the services business within GE Aviation’s $15 billion Commercial Engine & Service franchise and oversees a team of 7,000 employees responsible for

on-wing support, repair, used materials and overhaul of global airlines fleets.

MRO Americas, the largest trade show in the world dedicated to aviation maintenance, repair, and operations (MRO), kicks off this week in Dallas. Aviation MRO industry leaders, including airlines, OEMs and MRO service providers like GE Aviation, leasing companies, aviation authorities and regulators, are part of more than 10,000 expected attendees.

The show is a great chance to highlight how far GE Aviation has come, what we’re doing to continuously improve our services business and help grow the MRO industry.

The last two years have been one of the most challenging periods the aviation industry has ever experienced with supply shortages, logistical constraints and other pandemic-induced strains impacting the entire MRO ecosystem.

However, as an industry, we are moving closer to a full recovery. With the exception of China and the impact of the Russian conflict, global departures are on track to reach pre-COVID levels by next year. This increase in utilization translates into a growth in shop visits, with our business projecting 25% more volume in 2022 than in 2021.

For GE Aviation, this is much more than a service recovery. This is an opportunity.

- We participate in a unique open network with other providers. This means we all compete and invest to win shop visits to support GE and CFM International* customers. That's good because it means we are all innovating new ways of creating solutions for customers, giving them greater flexibility and choice of where they want their assets served.

- We have a large, young fleet of engines. Our CFM56 product illustrates the growth we can anticipate over the next decade. There are over 19,000 CFM56 engines flying. Over half have not seen a single shop visit, and another quarter have only had one. This represents huge opportunity for the MRO ecosystem. Our widebody engines, like the GE90 and CF6, continue to see real activity from operators around the world, also driving significant shop visit volume. Our new products like GEnx and LEAP will contribute even more growth over the next 10 years as they start to drive a larger proportion of shop visits. All these dynamics represent significant opportunity, for GE, CFM and our open network of services providers.

- We invest in our materials to reduce the cost of ownership of our products throughout their life. GE and CFM are the largest used serviceable material provider for our products. We also allocate significant resources toward industrializing repairs. Currently, there are more than 21,000 repairs in our catalogs. Additionally, GE and CFM industrialized more than 1,500 repairs in 2021, increasing their capability. This wide availability of used serviceable material and repairs allows our MRO ecosystem the flexibility required to provide competitive shop visit and repair pricing and translates into improving cost of ownership for our operators over their asset ownership horizon.

- We continually work with our customers to better understand their operating parameters, fleet strategies, and how best to give them the work scope flexibility that they may need and want.

These are all great tools to give our customers the world-class support they demand, and more importantly, keep their aircraft flying. However, over the course of the pandemic, it was evident we needed to evolve our businesses faster to meet our customers’ needs.

During the downturn, we put an emphasis on controlling the things within our control. We did this by embracing lean principles, optimizing our shop capacity, and deploying new technologies. We focused each day on how to drive greater capability to ensure we are stronger coming out of the pandemic than when we came in.

For example, in the last year we transitioned 550 repairs from dedicated component repair sites to our overhaul sites. Moving capability closer to where work is being done reduces turnaround time and cuts logistics costs. It also has an impact on our sustainability mission, saving around 18,000 miles per parts shipped, as well as packing.

We are finding ways of driving real opportunity to create new sources of productivity, and more importantly, opportunity to look at how we can better take care of our customers.

Our shops are thinking about lean not as an initiative, but as a movement. Together, we’ve taken a deep dive into standard work. We ask ourselves: what are the things that we want to consistently do to make sure we see our processes perform as close to optimal as possible? Once we have these standards, we create a set of rules around a work process. Once we have rules, we can begin to teach machines how to process these rules on their own. This unlocks the power and potential of AI and automation in the aviation services space.

This isn’t just talk. It has enabled AI white-light inspections on CFM56 blades, resulting in an 80 percent reduction in turnaround time, and 90 percent reduction in human intervention. It has also helped us find new ways to automate repairs using additive, eliminating traditional welding, reducing blade tip repair cycle time by 50 percent.

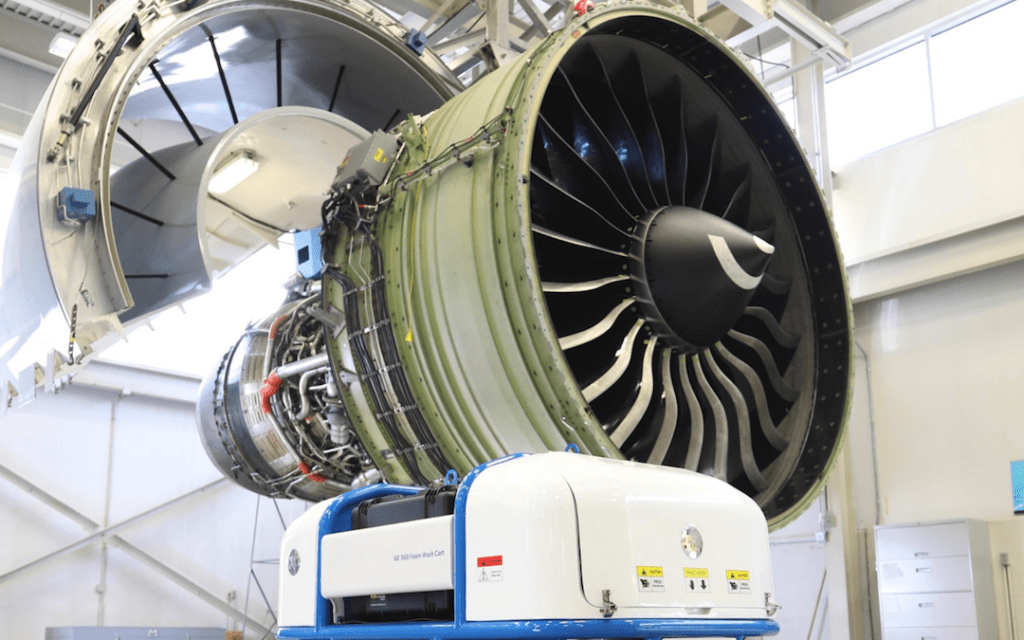

We are also working with customers to keep their engines on-wing, longer, all together. Our 360 Foam Wash product and procedure for example (pictured above) is supporting the recovery of engine performance. It’s enabling our operators to use their engines longer before coming in for their next shop visit. It’s try-storming like this that is allowing us to rapid launch new sources of productivity-enabling capabilities in our network.

Bottom line: today’s hard work is giving us more leverage to support the demand curve, it’s enabling a competitive MRO environment, and helps us to meet our customers’ needs. And there are more innovations yet to come.

*CFM International is a 50/50 joint company between GE Aviation and Safran Aircraft Engines