GE Aviation's Quick Six with Sourcing Commercial Leader Jack Cohen

June 27, 2019 | by Sarah Sampson

From working parents to military veterans, GE would not be the company it is today without its employees. We created “Quick Six” to celebrate our diverse talent by asking employees six questions that uncover the unique ways that they contribute to GE and the world.

In our next installment of Quick Six, we sit down with Jack Cohen, who recently joined GE Aviation Sourcing in Evendale, Ohio, as a Structural Castings Commercial Leader after a tour of duty at SpaceX in Hawthorne, California, where he served as a Commodity manager for Mechanisms and New Product Introduction.How long have you been in your position and can you give us a brief overview of what you do?

I have been in my position for 40 days! Working from the Evendale, Ohio, facility as the Structural Castings Commercial Leader, I am tasked with three things: Get castings for engines that are of the highest quality, are fair and reasonably priced, and delivered on time to meet our production needs.

Coming from SpaceX is pretty cool. What was it about GE that attracted you to your current role?

In this role with GE I get to help build the same engines that safely carry me and my family to destinations all over the world. It’s a very neat experience the first time you get on an airplane, look out the window, and see an engine that you are now deeply familiar with. Also, due to the scale of operations at GE there are always some very interesting and rewarding challenges to overcome.

What motivates or inspires you?

Being a part of a high performing team that can set some lofty goals always brings out my best work. I absolutely love learning not only new things but also different ways of doing some of the things I am familiar with. I am usually very engaged in my work when the challenges are dynamic and everyone around me is moving with a sense of urgency and purpose.

What has been a lesson you’ve learned that you’ve carried with you to GE? Do you have any advice for other people?

Jack with his wife Morgan and astronaut José Moreno Hernández, who was a mission specialist on the STS-128 mission which launched on August 28, 2009.

Jack with his wife Morgan and astronaut José Moreno Hernández, who was a mission specialist on the STS-128 mission which launched on August 28, 2009.

Most of the time an organization does not realize that most of the metrics, initiatives, shake-ups, goals, and activities designed to “improve” can be boiled down to one overarching goal: reduce variability in your inputs/outputs.

As a supply chain organization, for example, we measure On Time Delivery (OTD). When the department head drives for the supply base to reach a 95% OTD score, what he/she is saying, whether he/she realizes it or not, is that they want to be able to predict when product is going to hit the docks. Most of the time it’s not about a part taking 10 weeks to make versus 15 weeks, but about knowing how to plan for the time the parts are arriving ready for build.

Sure, material savings are nice but a huge factor of a Long-Term Agreement (LTA) negotiation is about protecting the cost of a part and being able to predict years into the future how much a part is going to cost. This way the business can plan for expenses and be able to price the product for sale more accurately. This means that an advantage of an LTA is to reduce variability in the price that we pay for parts.

At the end of the day, if you focus your day-to-day activities and aim to develop processes or drive actions that will ultimately reduce variability in your inputs to the business, you will be successful in accomplishing most of your goals.

We know you’re new here, but can you share your favorite engine and why? Can you draw a picture?

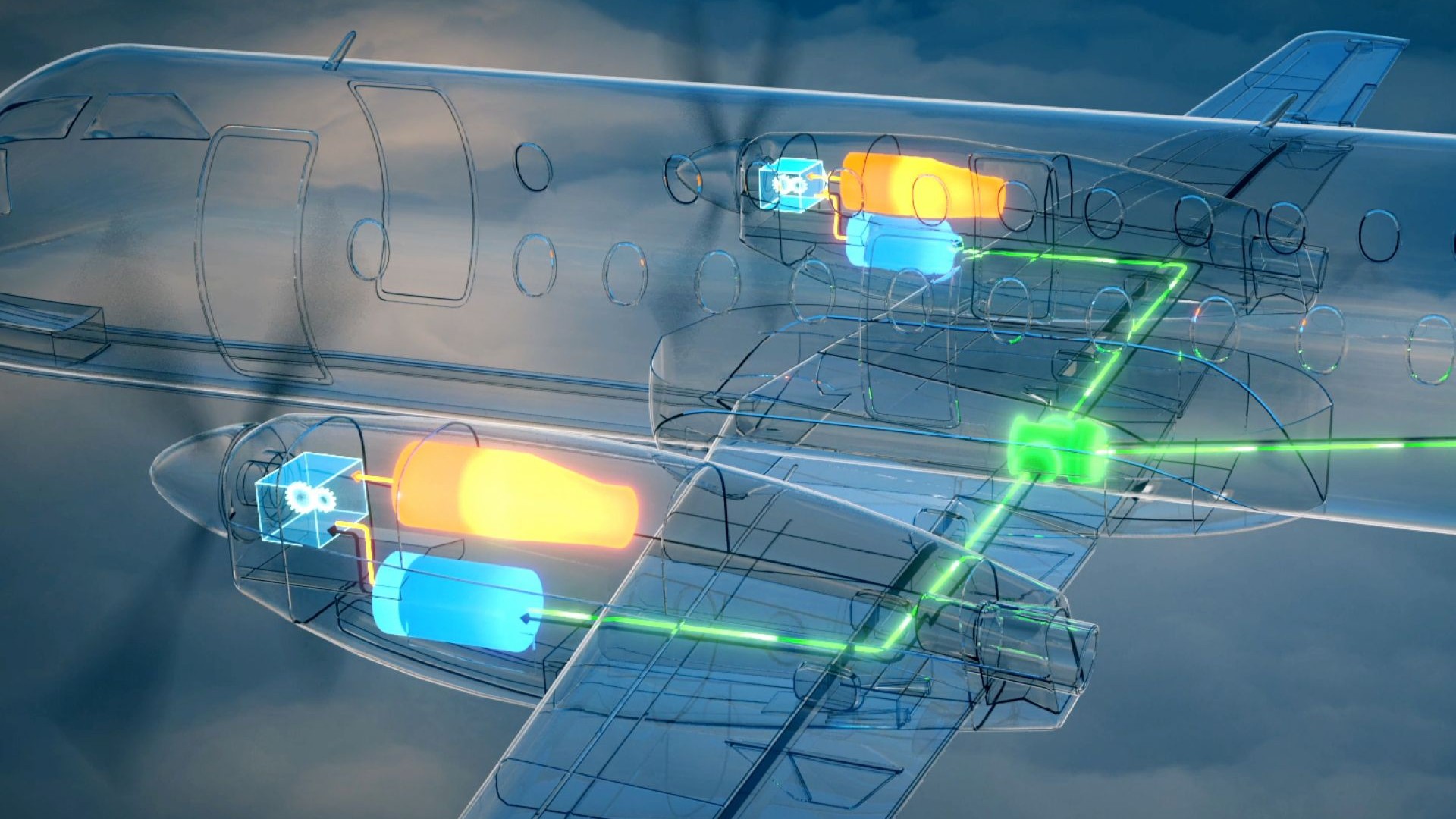

Oh, that’s simple! I am a huge space and aviation geek and I like to follow some of the science projects other companies are doing to improve the technology in the field. Did you know that NASA’s new X-Plane, which is supposed to test new and innovative ways to enable commercial supersonic passenger air travel over land, will use a GE F414 engine? That automatically puts it at the top of my list as far as engines with a cool factor on them!

As far as drawing a picture, here is my best shot without looking at a reference picture.

What’s a surprising passion that people might not know about you?

When I was 23, I opened a pizza shop in Dallas, Texas, and operated it every night after my normal 45 hours/week job. It was a tough time and some long hours, but I learned a tremendous number of things—among them, a new appreciation for the term “small working capital.”

- Quick Six with Tiffany Liang, Materials Leader for the LEAP-1A and -1B Core Assembly in Lafayette, Indiana.

- Quick Six with Katie Schafer, Quality Engineer in Asheville, NC.

- Quick Six with Carlos Duenas, lead mechanic at GE Aviation Flight Test Operations, located in Victorville, California.

- Quick Six with Bryne Berry, Environmental Barrier Coating Engineer at GE Aviation in Evendale, OH.

- Quick Six with Dale Hughes, Assembly & Test Technician in Durham, NC

- Quick Six with Terrance Brand, Staff Engineer for GE Aviation in Hooksett, NH.

- Quick Six with Flavio Caciuffo, engineer at GE Aviation business, Avio Aero.

- Quick Six with Phil Woniger, Senior Account Sales Manager, at GE Aviation in Savannah, Georgia.

- GE Aviation’s Quick Six with Mike Bonacum, T901 Technology Maturation Leader at GE Aviation in Lynn, MA.

- GE Aviation’s Quick Six with David Burns, CIO of GE Aviation in Cincinnati, Ohio.

- Quick Six with Mike Bonacum, a T901 Technology Maturation Leader at GE Aviation in Lynn, MA.