The Need for Speed: GE Aerospace Is Using Ramjet Technology to Up the Ante in Hypersonic Flight

January 13, 2025 | by Chris Noon

Flying from New York City to Los Angeles in less than an hour sounds like a science fiction fantasy, but aerospace engineers are steadily solving the problem of hypersonic flight, which would allow aircraft to safely shoot through the skies at five times the speed of sound. Yet as they figure out how to bend time in passenger travel, engineers are attending to an even more urgent priority: harnessing the extraordinary capabilities of hypersonics in the name of global security.

“Our adversaries have pushed the industry into an upswing,” says Dean Modroukas, general manager for hypersonics at GE Aerospace, referring to the world’s current geopolitical landscape. Modroukas explains that the race is on to develop hyper-efficient propulsion systems that can travel much farther and much faster, dramatically compressing an adversary’s time and room to maneuver.

GE Aerospace engineers are working hard to ensure that the United States and its allies will prevail in that race. Fresh from a year of successful ground-level tests that have catapulted them toward their goal of hyper-efficient, high-speed, and long-range hypersonic flights, engineers are now preparing to prove their breakthrough technologies in the only arena that matters: the skies.

Dr. Modroukas, who headed up engineering at the Bohemia, New York–based hypersonics company Innoveering until it was acquired by GE Aerospace in 2022, is laser-focused on ensuring that his team’s hypersonic engines will be mission-ready. “You can do all the design, analysis, and ground tests that you want, and they’re a crucial part of the overall life cycle of getting systems into the field,” he explains. “But getting to flight, and getting the system into a relevant environment and mission? That’s where the rubber meets the road. Fortunately, GE Aerospace is giving us the flexibility and freedom to really move quickly in this space, and make the investments that are necessary to meet the milestones.”

Hypersonic Technology at GE Aerospace: A Match in a Hurricane

A quick primer on hypersonic technology. The air-breathing ramjet engines that enable hypersonic flight are very different from the turbojets and turbofan engines on passenger aircraft. Instead of using moving components, like compressors and turbines, they depend on specially engineered air inlets that compress the air to the right pressure for combustion.

Like cars that need to be in top gear to achieve maximum velocity, a standard ramjet propulsion system ignites only when the vehicle achieves supersonic speeds that are greater than Mach 3, or three times the speed of sound. This is why ramjets have traditionally relied on rocket boosters or special turbo-ramjet engines to achieve the extra throttle for ignition.

“The challenge of igniting the hypersonic engine is often compared to lighting a match in a hurricane,” says Modroukas.

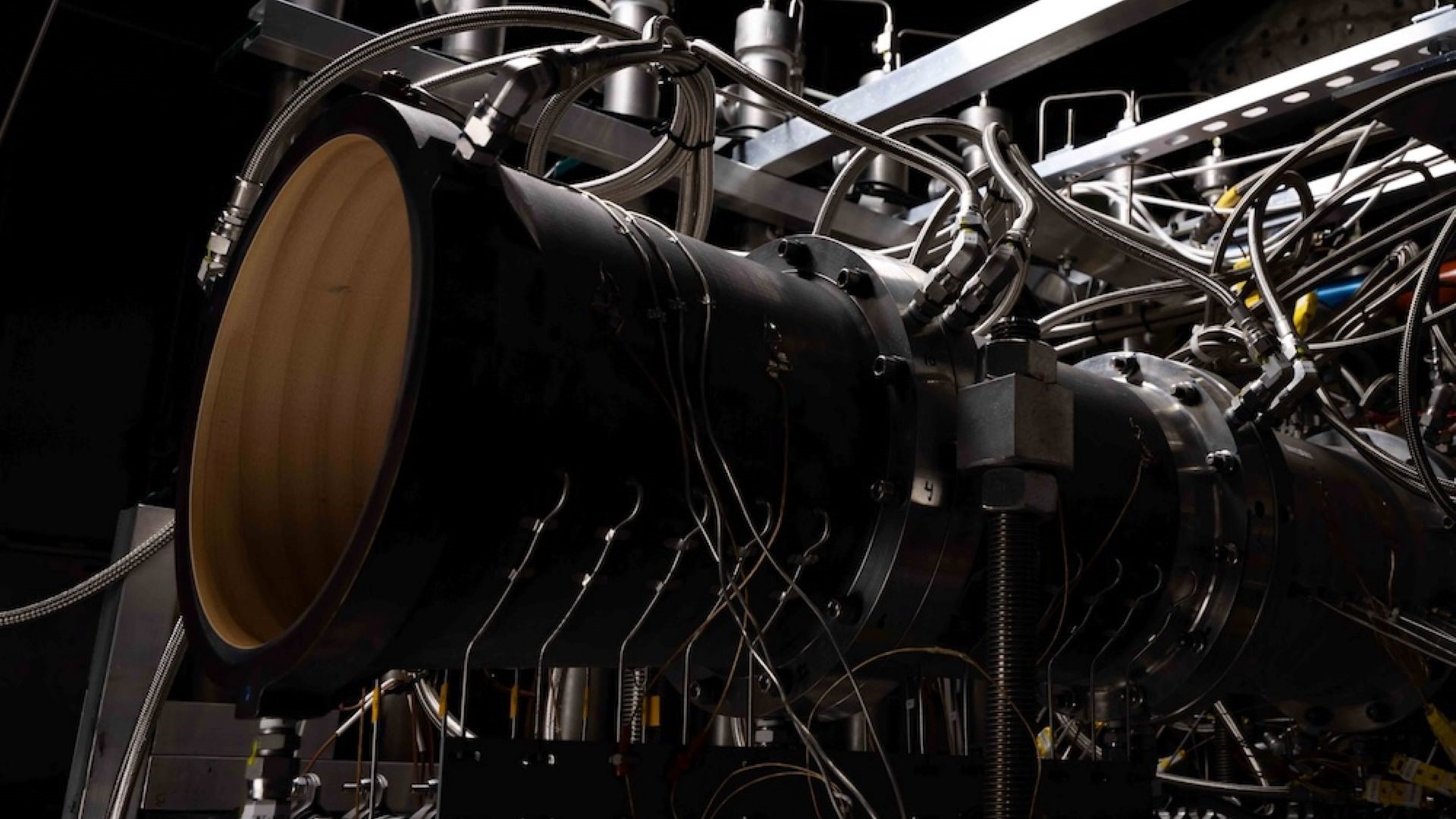

For more than a decade, GE Aerospace has been working with NASA and other research partners to make that happen using pulsed detonation engine technology, which burns fuel in waves of small, controlled explosions instead of standard combustion. In late 2023, it demonstrated a world first at its research center in Niskayuna, New York: a hypersonic dual-mode ramjet (DMRJ) rig that harnesses rotating detonation combustion (RDC) technology within a supersonic flow stream.

The state-of-the-art technology generates higher thrust from a smaller engine size and weight, which allows for game-changing efficiency gains. GE Aerospace’s hypersonic propulsion technologies will propel air-breathing missiles and aircraft seamlessly across a range of flight Mach numbers while enabling the vehicle to fly in unpredictable, hard-to-track paths, providing exactly the kind of evasive measures sought by the U.S. Department of Defense.

In mid-2024, the team completed another ground test at GE Aerospace’s high-speed propulsion testing facility in Evendale, Ohio. The engineers showcased an additively manufactured DMRJ boasting a threefold increase in airflow compared with previously flight-tested hypersonic technology demonstrators. Modroukas called it “a tremendous success, both from a combustion performance and thermal structural perspective.”

“We got that designed and built in eight and a half months, and achieved first fire within 11 months,” he adds. “That pace is going to continue for us, and we don’t expect it to slow down.”

The Next Step: Getting to Flight Using Ramjet Technology

The next stage of development will be key to eventually getting the ramjet technology airborne. In 2025, “we’ll be scaling up what we’ve done over the past 18 months and start to integrate [these building blocks] into a full propulsion system,” says Modroukas. Engineers will start by fine-tuning the advanced controls of their systems and applying advanced materials found in GE Aerospace’s jet engine technology.

Modroukas relishes the prospect of his team’s systems finally taking to the skies. “Ground testing allows you to understand everything going on with your system in terms of aerodynamics and propulsion,” he says. “But flight testing allows you to learn and improve after every activity.”

GE Aerospace’s scale and structure will help Modroukas and his team to rapidly ascend the steep learning curve. “We’ve got multiple ground test facilities, and amazing prototype manufacturing and design and analysis capabilities,” he says, “which are a big differentiator.”

Modroukas will be in his element. The veteran engineer began his career working the hypersonic testing rigs at Long Island, New York–based General Applied Science Laboratory, the company founded by the legendary Italian scientist Antonio Ferri. “It was one of the most exciting times of my younger career: time in the labs, building the rigs, doing the ground tests, and reviewing the data,” he says. “There’s no better feeling than seeing the blue flame coming out of a well-performing engine.”

It’s a sight that he’s hoping to get used to in the coming year.