How RISE Arose: The Story Behind Decades of Innovations That Bring CFM to a Pivotal Moment

June 19, 2023 | by GE Reports

In 1941, the United States government asked GE to develop the first American jet engine. Allied defense, industrial collaboration, technological advancement, and economic growth were at stake. GE delivered the very next year.

Now, more than 80 years later, GE Aerospace finds itself at the cusp of another era-defining moment. With climate change impacting communities and economies around the world, the aerospace industry is in the midst of what feels to some like a seismic shift.

To meet this challenge, CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines, unveiled the Revolutionary Innovation for Sustainable Engines (RISE) program in 2021. The CFM RISE program aims to reduce fuel consumption and carbon dioxide emissions by more than 20% compared with today’s most efficient aircraft engines. Improved engine efficiency is key to helping the aviation industry achieve a larger target: net zero CO2 emissions by 2050.

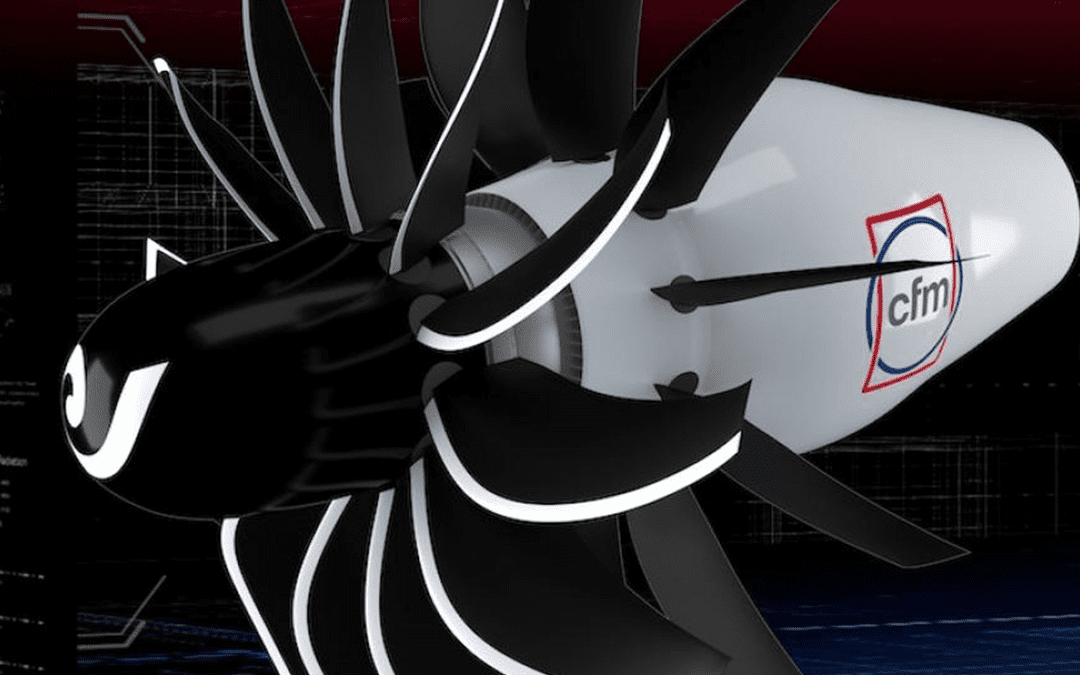

Arjan Hegeman, GE Aerospace’s general manager of advanced technology. Credit: GE Aerospace. Top: A prototype of the CFM RISE open-fan concept. Credit: CFM International.

Arjan Hegeman, GE Aerospace’s general manager of advanced technology. Credit: GE Aerospace. Top: A prototype of the CFM RISE open-fan concept. Credit: CFM International.

In terms of sustainability, it’s a bold goal. But as Arjan Hegeman, GE Aerospace’s general manager of advanced technology, recently put it: “History will judge us to be on the right side of the fence.”

Notwithstanding the urgency of the moment, the groundwork laid for the CFM RISE program has been decades in the making. Indeed, the innovations at the heart of the program — open-fan architecture, carbon-fiber composites, ceramic matrix composites, and additive technology — are the result of years of painstaking research, testing, and validation.

One particular advancement that CFM RISE will utilize involves a variable-pitch engine design. Variable-pitch fan blades were first put into action in 1978 when GE teamed with NASA to develop the Quiet Clean Short-Haul Experimental Engine (QCSEE). The QCSEE had an unprecedented bypass ratio at the time of 11:1, meaning that for every unit of air that passed through the combustion chamber, 11 units bypassed the combustion process. (The bypass ratio describes the relationship between the thrust that the rotor, or fan, generates and how much energy it takes to drive the rotor.) At 11:1, the QCSEE was highly efficient.

The innovation at the heart of the RISE program is the open-fan architecture, also known as an “unducted fan,” which was first developed by GE and Safran in the 1980s. Open-fan technology derives its name from the absence of a case surrounding the fan. The architecture enables the engine to maintain the speed and performance of traditional turbofans while further increasing fuel efficiency and lowering carbon output. When the GE36, an experimental engine, debuted at the Farnborough International Airshow in 1988, it made a splash with its two sets of fully exposed, counter-rotating fan blades.

The CFM RISE program’s single-stage, variable-pitch demonstrator engine with stationary outlet guide vanes builds on the innovations GE Aerospace and Safran developed in the QCSEE and GE36 experimental engine programs. While the single set of variable-pitch fan blades rotate in front, a second set of outlet guide vanes help guide airflow.

The GE36 engine, developed in the 1980s by GE and Safran. Credit: GE Aerospace.

The GE36 engine, developed in the 1980s by GE and Safran. Credit: GE Aerospace.

Describing the work that GE Aerospace has done to take the technology even further in the RISE program, Hegeman points out that “our accuracy and capability of understanding how [an open-fan engine] works, and our optimization of the overall designs, have enabled us to go to a single-stage fan with stationary outlet guide vanes of a smaller diameter while meeting the performance target as well as the acoustics targets.”

The result is an open-fan engine with higher fuel efficiency, lower emissions, less noise, and turbofan flight speeds. “Bypass ratio is the name of the game,” Hegeman adds. “This is physics. It works. There’s no way you can ever get this level of efficiency in your fan when you put a duct around it.”

Despite realizing significant fuel savings, the GE36 fell victim to a dramatic drop in fuel prices in the late 1980s. While it never was put to use commercially, the technologies that engine pioneered helped chart the course of aviation for the next 30 years. Its carbon-fiber composite fan blades helped give birth to GE Aerospace’s higher-bypass jet engines, such as the GE90, the GEnx, and the GE9X. These, in turn, helped plane-makers build efficient, twin-engine long-haul jets like the Boeing 777, 787 Dreamliner, and 777X.

When the GE90 entered service in 1995, it became the first certified commercial jet engine to use lightweight carbon-fiber composite fan blades, which reduced weight and greatly increased fuel efficiency. Since then, GE jet engines have logged more than 200 million flight hours using composite fan blades. (Fast fact: The GE90-115B went on to set a Guinness World Record in 2002 by producing 127,900 pounds of thrust, making it the world’s most powerful commercial aircraft engine. It was only eclipsed in 2019, when the GE9X achieved 134,300 pounds on the test stand.)

The GE90, a mid-1990s model that was the first certified commercial jet engine to use lightweight carbon-fiber composite fan blades. Credit: GE Aerospace.

The GE90, a mid-1990s model that was the first certified commercial jet engine to use lightweight carbon-fiber composite fan blades. Credit: GE Aerospace.

But building a bigger and lighter fan isn’t the only way to make an engine more efficient. “Every time you make the fan a little bit bigger, you also add a little bit more drag” due to the bigger casing around the fan, Hegeman notes.

In addition to the open-fan design and carbon-fiber composite fan blades, the CFM RISE team is focused on improving the core of the engine, the section that holds the compressor, combustor, turbine, and other components that convert the fuel’s energy into efficient rotary motion. To do this, they’re using a groundbreaking material that has been tested inside both the CFM LEAP and GE9X engines: ceramic matrix composites. The CMC parts that GE Aerospace has developed over the past decade are one-third the weight of steel but can withstand temperatures as high as 2,400 degrees Fahrenheit, which is beyond the melting point of many advanced metallic superalloys.

When the CFM LEAP engine went into service in 2016, it marked the first use of CMCs and 3D-printed additive parts in the hot section of a commercial aircraft engine. These parts, which are lighter, stronger, and more heat-resistant and damage-tolerant than traditionally manufactured metal parts, helped make the LEAP engine 15% more fuel-efficient than its predecessors.

The CFM LEAP, from 2016, which marked the first use of CMCs and 3D-printed additive parts in the hot section of a commercial aircraft engine. Credit: CFM International.

The CFM LEAP, from 2016, which marked the first use of CMCs and 3D-printed additive parts in the hot section of a commercial aircraft engine. Credit: CFM International.

Taking a lead from the LEAP program, the engineers working on the RISE program are studying how to make a more compact engine core. Through another multimillion-dollar partnership with NASA, announced in late 2021, GE Aerospace has been awarded contracts to test and mature new jet engine core designs, including compressor, combustor, and high-pressure turbine technologies to improve thermal efficiency.

Last year, GE Aerospace teamed up with NASA again to test a megawatt-class, multi-kilovolt hybrid electric propulsion system in simulated high-altitude conditions (up to 45,000 feet) for the first time. GE Aerospace has spent more than a decade developing the hybrid electric system, building on its expertise in electric motors, generators, and power converters. The company will continue testing its hybrid electric system as part of NASA’s $260 million Electrified Powertrain Flight Demonstration (EPFD) project, with the aim of performing ground and flight tests by the mid-2020s. The CFM RISE program plans to incorporate this hybrid electric capability to optimize engine efficiency and lower CO2 emissions in its open-fan concept.

In 2016, this megawatt-class GE motor/generator electrically powered an 11-foot diameter propeller on a test stand. Credit: GE Aerospace.

In 2016, this megawatt-class GE motor/generator electrically powered an 11-foot diameter propeller on a test stand. Credit: GE Aerospace.

It’s important to remember what’s driving all of this marvelous engineering know-how: climate change. Single-aisle planes could make up 70% of the world’s rapidly growing commercial aviation fleet in the near future. And aviation currently accounts for roughly 2% of global CO2 emissions.

That explains the urgency as well as the excitement behind the CFM RISE program. “We are convinced that with climate change the cost of carbon emissions is going to make sure that the cost of fuel, whether it’s carbon-based, synthetic, biomass, or completely alternative fuels like hydrogen, is going to increase over time,” Hegeman says. “So, investing in fuel efficiencies is not only the right thing to do for the planet and for following generations, it’s also going to be much more of an economic differentiator for the operators compared to what it was in the past.”

See our timeline below about the technologies behind RISE — and don't miss this video about open fan and the RISE Program by pilot and YouTube sensation Petter Hörnfeldt, on his Mentour Now! channel. GE Reports recently profiled Hornfeldt here.