New Sustainability Report Shows How GE Aerospace Is Moving Innovation Forward. These Employees Are Making It Happen.

September 19, 2024

Over the past two years, GE Aerospace has transformed itself. On April 2, it became a standalone company, and today it is releasing its first Sustainability Report. The report is a deep dive into the four core principles of its sustainability framework: safety, environment, people, and governance. But amid the changes, one constant is the company’s long heritage of moving innovation forward, as is made clear in the Sustainability Report through its role supporting the aviation industry’s ambition for net zero carbon emissions by 2050.

The company’s purpose is both simple and profound: “to invent the future of flight, lift people up, and bring them home safely.” GE Aerospace employs 52,000 people around the world, including 12,000 engineers. Meeting the challenges of the future will require a new landscape of breakthrough technologies. “To change the future of flight and make it more sustainable, we have to change the aircraft engine,” says Mohamed Ali, senior vice president of engineering for GE Aerospace.

Challenges like these are what motivate those 52,000 employees to come to work each day. Meet four of those people who bring the company’s sustainability efforts to life around the world.

Putting Safety First: GE Aerospace Employee Terri Braun Voutsas

Three of every four commercial flights today are powered by engines made by GE Aerospace or one of its joint ventures, and the company recognizes this means an awesome responsibility to get passengers to their destinations without incident. “Underpinning our commitment to innovation is our relentless focus on safety, quality, delivery, and cost — in that order,” says H. Lawrence Culp Jr., chairman and CEO of GE Aerospace.

Safety is literally in the job description of Terri Braun Voutsas: She is the company’s director of flight safety. At GE Aerospace today, every square foot from the shop floor to the boardroom is an open, safe space for raising concerns, and teams of engineers and technicians are constantly evolving newer and better protocols for building and inspecting engine parts.

One of Braun Voutsas’ main duties is working with the company’s safety management system (SMS). In 2013, a decade before the Federal Aviation Administration proposed making it a requirement, GE Aerospace became the first aerospace manufacturer to create an SMS. It’s because of the exhaustive work of Braun Voutsas’ teams that the company recorded zero jet engine incidents in 2023, improving on a strong five-year record of 0.04 incidents per one million departures.

Braun Voutsas came to the company in 1989, as an engineering co-op with a mind for math. From the start, she felt the weight of responsibility every time she crunched the numbers. “Even the slightest miscalculation on the energy of a rotating part could have a negative impact on the airplane,” she says. “I decided to take up a role, maybe stay five years, and then go someplace else,” she says. “I’m still here 35 years later.” Read Braun Voutsas’ story here.

Accelerating Smart Innovation: GE Aerospace Employee Cassi Miller

For the future of more sustainable flight, GE Aerospace is taking an across-the-board approach, advancing the development of efficient aircraft engines compatible with alternative fuels and collaborating across the industry. For example, the CFM* Revolutionary Innovation for Sustainable Engines (RISE) program — one of the largest technology demonstration programs in company history — seeks to achieve at least 20% better fuel efficiency than the most efficient commercial engines today. In the past year, teams simulated Open Fan engine architecture performance using the world’s fastest supercomputer and completed more than 250 tests for the RISE program.

In 2024, GE Aerospace announced that, along with NASA, it is developing a hybrid electric demonstrator engine — a modified Passport engine with hybrid electric motors and generators in a high-bypass commercial turbofan.

As senior staff engineer for the CFM RISE program, Cassi Miller knows that engine development doesn’t just happen in the office. Last year, she and a team of engineers flew in a chase plane behind a Boeing 737-10 with CFM LEAP-1B engines operating with sustainable aviation fuel (SAF) to study how SAF impacts contrail formation. “When the RISE program kicked off,” Miller observes, “we were really focused on minimizing CO2 and fuel burn. But now that the science is starting to tell us that there are other pieces that contribute to climate impact, we’re putting those in as well, to make sure that we’re really making a more sustainable engine at the end of this technology program.” Read more about Miller and her work.

Optimizing Operations: GE Aerospace Employee Cleber Barbosa

GE Aerospace is also using FLIGHT DECK, its proprietary lean operating model, to reduce emissions in its own operations, supporting its goal to have net zero carbon emissions for Scope 1 and 2 by 2030. This systematic approach brings exceptional value, as measured through the eyes of customers. It is the means by which GE Aerospace will turn its strategy into sustainable results and deliver on its purpose today, tomorrow, and in the future.

Kaizen events are one of the tools used to drive continuous improvement. During a kaizen event in Celma, Brazil, a cross-functional team made up of subject matter experts, local employees, and executive leadership were focused on identifying projects to reduce the site’s energy consumption, uncovering opportunities to save 8,029 megawatt-hours (MWh), about 40% of its total energy usage. One opportunity the team identified was to shut down two different machines, which was accomplished by updating the operators’ standard work to shut off the machines at the end of their shifts. This simple change reduced energy usage by 1,970 MWh per year and saved around $366,000.

“Energy treasure hunts connected with a Shingijutsu event are an efficient initiative to identify energy kaizens that reduce costs and drive reductions in emissions,”said Cleber Barbosa, environmental manager for the Celma site. “It’s important to create energy conservation awareness and commitment. As the team’s efforts show, small human behavior changes can have a big impact.”

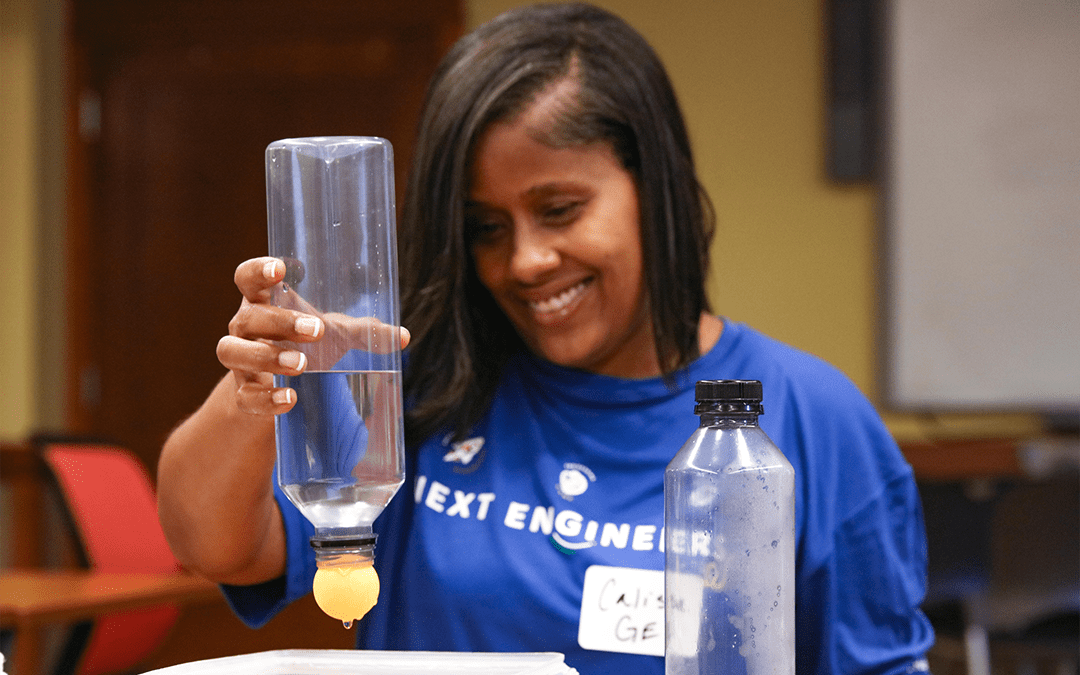

Empowering People and Communities: GE Aerospace Employee Calisa Horton

Respect for people is a core fundamental of FLIGHT DECK, and GE Aerospace is committed to attracting, retaining, and developing the best talent and “lifting people up in the communities where we live and work.” These efforts are evidenced in its launch of the GE Aerospace Foundation and its investments in Next Engineers, workforce development, disaster relief, and humanitarian aid, all outlined in the Sustainability Report.

“Our organization rests on the backs of its people, and this work is an investment in the environment in which we want to work,” says Chief Diversity Officer Germaine Hunter. “Our vision is for every single employee at GE Aerospace to feel respected, included, and empowered to reach their fullest potential.”

Calisa Horton, a finance senior staff technical product manager based in Evendale, Ohio, exemplifies this commitment both inside and out of GE Aerospace. At work, there’s nothing Horton enjoys more than “making that person’s job easier” when a fellow employee encounters an obstacle. She’s grateful that the company allows her “to work on continuous improvement initiatives that help stabilize the system.” As a volunteer in the community, she’s deeply involved in Next Engineers, a program to bring more young people into the engineering professions. This includes leading the successful Engineering Discovery program, which has been integrated into seven Cincinnati-area schools. In 2023, her efforts earned her GE Aerospace’s “Lifting People Up” award. Read more about Calisa Horton.

Future Focus

Today’s Sustainability Report highlights how GE Aerospace is moving innovation forward to strengthen safety, reduce emissions, and lift people up both inside GE Aerospace and in the communities where it operates. None of it would be possible without the support of its 52,000 employees around the world.

As Culp writes in the Sustainability Report, “GE Aerospace technology is central to achieving the industry’s long-term climate goal of net zero carbon emissions. This is both an incredible responsibility and an unparalleled opportunity to advance a safer and more sustainable future.”

*CFM International is a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.