It takes more than a village to build a jet engine. In fact, it takes six countries, 12 states and 21 GE manufacturing sites providing 1.1 million total parts to form one GEnx jet engine. With more than 1,600 GEnx-1B engines sold worldwide, that means 1.76 billion parts come together to form the fastest-selling, high-thrust jet engine in GE Aviation history.

And it’s the GE sites, partners and joint ventures where the components and technologies are manufactured that make the GEnx 15 percent more fuel efficient compared to GE’s CF6 engine.

And it’s the GE sites, partners and joint ventures where the components and technologies are manufactured that make the GEnx 15 percent more fuel efficient compared to GE’s CF6 engine.

GE’s facility in Batesville, Mississippi produces the composite fan case, a first among jet engines. The breakthrough allows for greater engine durability and dramatic weight reduction. GE’s joint venture with Safran Aircraft Engines, called CFAN in San Marcos, Texas, lays up the 3rd generation composite fan blades. Based on the ratio of decibels to pounds of thrust, the GEnx is the quietest engine GE produces due to these large, more efficient fan blades that operate at slower tip speed, resulting in about 40 percent lower noise levels. Combined the composite fan case and fan blades, the GEnx is 350 lbs lighter per engine.

Hooksett, New Hampshire manufactures bladed disks called blisks for the high-pressure compressor. The GEnx creates more compression with fewer rows of blades than other engines due to three single-piece blisks; the blisks prevent air from leaking between the blades and disks. They save fuel, reduce components, cut maintenance and decrease noise.

Various components for the combustor are all manufactured and assembled in Terre Haute, Indiana. The GEnx features the first twin-annular pre-swirl (TAPs) combustor, a technology GE matured for almost a decade prior to the engine’s first rig tests in 2005. The key to TAPs is how air and fuel are pre-mixed before they are burned in the combustor. Air from the high-pressure compressor is directed into the combustor through two high-energy swirlers adjacent to the fuel nozzles. This swirl creates a more homogeneous and leaner mix of fuel and air, which burns at lower temperatures than in previous jet engine designs and reduces NOx gases as much as 55 percent below today’s regulatory limits and other regulated gases as much as 90 percent.

It’s GE’s Avio Aero facility in Italy that manufactures and assembles the accessory gearbox for the GEnx. This component of the engine turns generators to make electricity for the aircraft, enabling power for everything from the fuel pumps to the overhead reading lights.

Avio Aero also manufactures the Titanium Aluminide blades for the low-pressure turbine (LPT). The GEnx’s LPT is lighter and more efficient that its predecessor, due in part to the introduction of the Titanium Aluminide blades, reducing engine weight by approximately 200 pounds and contributing to increased fuel efficiency.

Durham, North Carolina is where the majority of these components come together for assembly in just 13 business days. When the Durham team has assembled the compressor, combustor, high pressure turbine and low pressure turbine, the GEnx propulsor is loaded on a truck bound for GE’s 7,000-acre Peebles, Ohio site where final assembly of the fan blade and fan case occurs. The complete GEnx is then run through a series of production tests and is off to Boeing for installation on a Boeing 787 Dreamliner, 747-8 Intercontinental or Freighter.

https://youtu.be/RZXAvplYv2o

And it’s the GE sites, partners and joint ventures where the components and technologies are manufactured that make the GEnx 15 percent more fuel efficient compared to GE’s CF6 engine.

And it’s the GE sites, partners and joint ventures where the components and technologies are manufactured that make the GEnx 15 percent more fuel efficient compared to GE’s CF6 engine.GE’s facility in Batesville, Mississippi produces the composite fan case, a first among jet engines. The breakthrough allows for greater engine durability and dramatic weight reduction. GE’s joint venture with Safran Aircraft Engines, called CFAN in San Marcos, Texas, lays up the 3rd generation composite fan blades. Based on the ratio of decibels to pounds of thrust, the GEnx is the quietest engine GE produces due to these large, more efficient fan blades that operate at slower tip speed, resulting in about 40 percent lower noise levels. Combined the composite fan case and fan blades, the GEnx is 350 lbs lighter per engine.

A GEnx accessory gearbox at GE Aviation's Avio Aero facility in Italy.

A GEnx accessory gearbox at GE Aviation's Avio Aero facility in Italy.

Hooksett, New Hampshire manufactures bladed disks called blisks for the high-pressure compressor. The GEnx creates more compression with fewer rows of blades than other engines due to three single-piece blisks; the blisks prevent air from leaking between the blades and disks. They save fuel, reduce components, cut maintenance and decrease noise.

Various components for the combustor are all manufactured and assembled in Terre Haute, Indiana. The GEnx features the first twin-annular pre-swirl (TAPs) combustor, a technology GE matured for almost a decade prior to the engine’s first rig tests in 2005. The key to TAPs is how air and fuel are pre-mixed before they are burned in the combustor. Air from the high-pressure compressor is directed into the combustor through two high-energy swirlers adjacent to the fuel nozzles. This swirl creates a more homogeneous and leaner mix of fuel and air, which burns at lower temperatures than in previous jet engine designs and reduces NOx gases as much as 55 percent below today’s regulatory limits and other regulated gases as much as 90 percent.

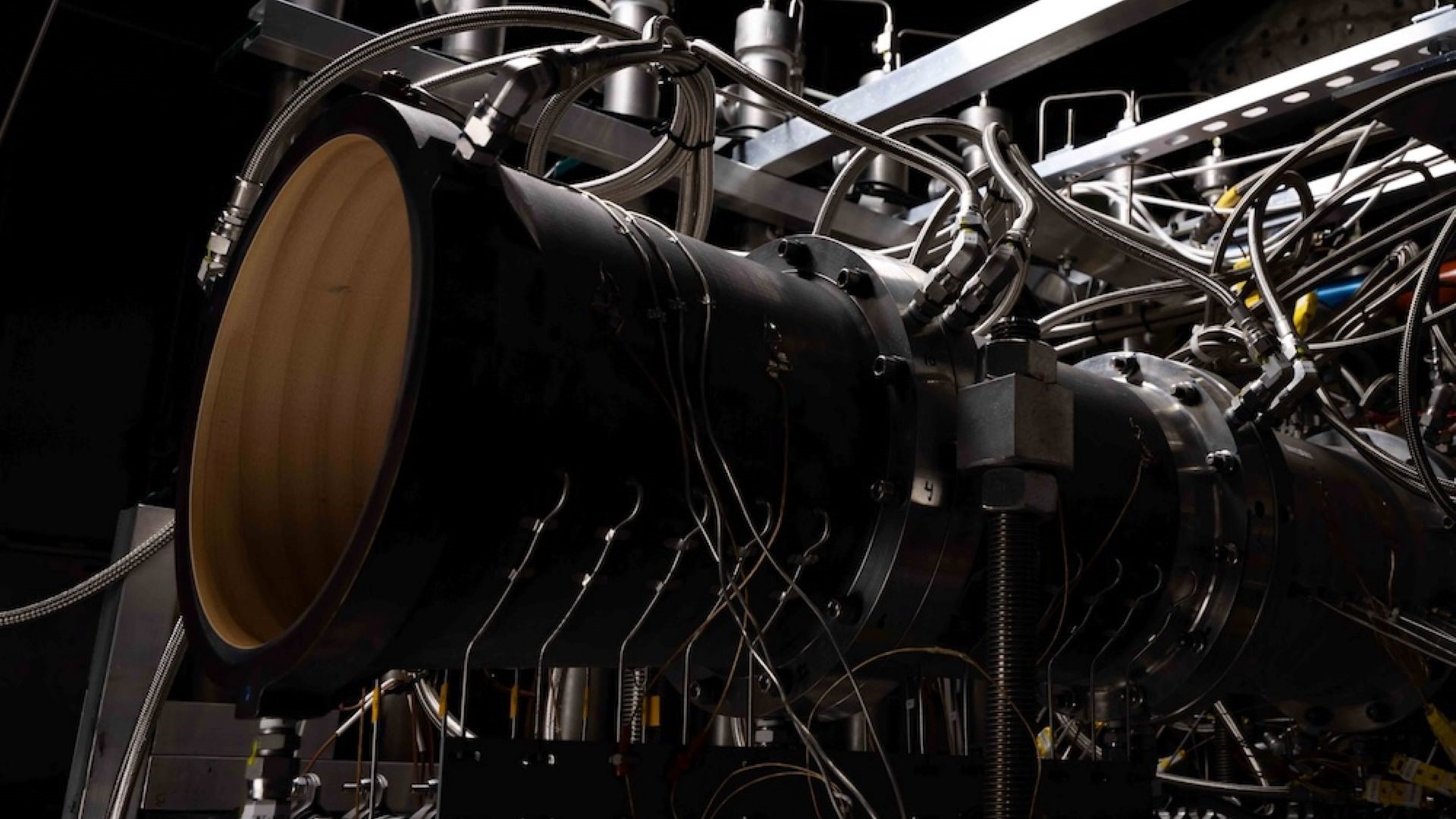

GEnx core assembly taking place at GE Aviation's site in Durham, North Carolina.

GEnx core assembly taking place at GE Aviation's site in Durham, North Carolina.

It’s GE’s Avio Aero facility in Italy that manufactures and assembles the accessory gearbox for the GEnx. This component of the engine turns generators to make electricity for the aircraft, enabling power for everything from the fuel pumps to the overhead reading lights.

Avio Aero also manufactures the Titanium Aluminide blades for the low-pressure turbine (LPT). The GEnx’s LPT is lighter and more efficient that its predecessor, due in part to the introduction of the Titanium Aluminide blades, reducing engine weight by approximately 200 pounds and contributing to increased fuel efficiency.

Several GEnx jet engines on the final assembly line at GE Aviation's Peebles Test Operations.

Several GEnx jet engines on the final assembly line at GE Aviation's Peebles Test Operations.

Durham, North Carolina is where the majority of these components come together for assembly in just 13 business days. When the Durham team has assembled the compressor, combustor, high pressure turbine and low pressure turbine, the GEnx propulsor is loaded on a truck bound for GE’s 7,000-acre Peebles, Ohio site where final assembly of the fan blade and fan case occurs. The complete GEnx is then run through a series of production tests and is off to Boeing for installation on a Boeing 787 Dreamliner, 747-8 Intercontinental or Freighter.

https://youtu.be/RZXAvplYv2o