Engineers in Arms: EDC Team in Warsaw Creates PPE Task Force

April 15, 2020 | by Joanna Apelska

As the number of positive tests for coronavirus began increasing in Poland at the end of March, the need for medical supplies skyrocketed, particularly in the capital of Warsaw where the outbreak was strongest. Seeing that need in their community, more than 100 volunteers from GE Aviation and GE Gas Power operating out of GE’s Engineering Design Center came together to form a working group dubbed “Engineers in Arms” and immediately set about producing critically needed personal protection equipment (PPE) and visors for neighboring hospital staffs.

After some research, the EDC team came across a few designs that would work best to support Polish medical staff. But they also discovered something else: they had neighbors on the EDC campus with the exact same idea. Their next decision was simple: join forces with their strategic partner, the Łukasiewicz Research Network–Institute of Aviation.

They quickly established the protocols for production. While the Institute provided the materials for creating the pieces, the EDC team came up with a production plan. Together they kicked off production and assembly of laser-cut visors and other forms of PPE. The volunteers operate 25 3D printers to create parts for the visors. Many have even put their own personal printers at home to use in the effort.

The EDC team also developed a partnership with the Polish Institute of Polymer Materials Engineering. One EDC additive engineer, teaming with his brother who works for the Polymer organization, arranged for donations of foil material to be cut on the laser plotter. This milestone allowed for mass production of about 1,500 items per day. The group assembled and packed boxes for the hospitals in shifts to keep up with supply and demand.

In one week, Engineers in Arms delivered 6,000 visors to local hospitals, and their production capacity continues to grow daily. With additional help from GE Volunteers, Tomasz Żochowski, EDC Additive Manager and main coordinator of Engineers in Arms, took up the challenge to create and coordinate an external production line in a different region of the country (the Kuyavian-Pomeranian Voivodeship). With production in that region up and running, the GE Volunteers were able to produce and deliver twice as much PPE daily.

Just like that, the Engineers in Arms’ actions snowballed. Now, they are doing much more than visors. Volunteers began printing special handles for opening doors (to avoid touching with bare hands), creating hand-made personal safety masks for seniors, producing spare critical parts for respirators used in Polish hospitals, and collecting necessary non-medical items that are in critical demand by hospitals. The team is also working on a so-called “last chance respirator” project with the Łukasiewicz Institute, creating a prototype that is easy to build and can be put to use in situations where certified respirators are unavailable.

The Engineers in Arms’ efforts have attracted a good deal of attention on social media. One particular comment on Twitter has raised even more support for their efforts.

“We have been contacted by private companies’ owners as well as other Polish GE sites wanting to dedicate their machines to support us. This would not have happened without Tweets like the one sent by the US Ambassador to Poland. It is a pure honor to have Ms. Georgette Mosbacher supporting our initiative,” said Żochowski.

Solidarity is embedded in the Polish DNA. The collective efforts of Engineers in Arms demonstrate their commitment to helping their community the best way they know how—with guts, compassion and innovation.

“None of the engineers in Engineers in Arms needed convincing to take part in these efforts,” said Żochowski. “We might have different skills and tasks but we all have one purpose as a team. And every day during this tough time, we go to bed happy, knowing that we made a difference.”

After some research, the EDC team came across a few designs that would work best to support Polish medical staff. But they also discovered something else: they had neighbors on the EDC campus with the exact same idea. Their next decision was simple: join forces with their strategic partner, the Łukasiewicz Research Network–Institute of Aviation.

They quickly established the protocols for production. While the Institute provided the materials for creating the pieces, the EDC team came up with a production plan. Together they kicked off production and assembly of laser-cut visors and other forms of PPE. The volunteers operate 25 3D printers to create parts for the visors. Many have even put their own personal printers at home to use in the effort.

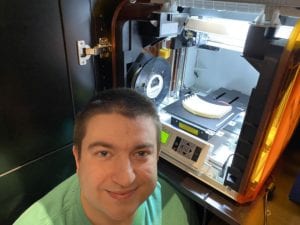

Top: Norman Kosmacinski, GE Gas Power Lead Engineer for Product Definition, assembling masks with 3D printed elements. Above: Michał Olejniczak, GE Aviation Senior Staff Software Engineer, is among two dozen EDC employees who put their own 3D printers to use to help boost production. (Image credit: GE Aviation)

Top: Norman Kosmacinski, GE Gas Power Lead Engineer for Product Definition, assembling masks with 3D printed elements. Above: Michał Olejniczak, GE Aviation Senior Staff Software Engineer, is among two dozen EDC employees who put their own 3D printers to use to help boost production. (Image credit: GE Aviation)

The EDC team also developed a partnership with the Polish Institute of Polymer Materials Engineering. One EDC additive engineer, teaming with his brother who works for the Polymer organization, arranged for donations of foil material to be cut on the laser plotter. This milestone allowed for mass production of about 1,500 items per day. The group assembled and packed boxes for the hospitals in shifts to keep up with supply and demand.

In one week, Engineers in Arms delivered 6,000 visors to local hospitals, and their production capacity continues to grow daily. With additional help from GE Volunteers, Tomasz Żochowski, EDC Additive Manager and main coordinator of Engineers in Arms, took up the challenge to create and coordinate an external production line in a different region of the country (the Kuyavian-Pomeranian Voivodeship). With production in that region up and running, the GE Volunteers were able to produce and deliver twice as much PPE daily.

A selection of parts for the thousands of masks, visors and other PPE produced at the EDC for local hospitals in Poland. (Image credit: GE Aviation)

A selection of parts for the thousands of masks, visors and other PPE produced at the EDC for local hospitals in Poland. (Image credit: GE Aviation)

Just like that, the Engineers in Arms’ actions snowballed. Now, they are doing much more than visors. Volunteers began printing special handles for opening doors (to avoid touching with bare hands), creating hand-made personal safety masks for seniors, producing spare critical parts for respirators used in Polish hospitals, and collecting necessary non-medical items that are in critical demand by hospitals. The team is also working on a so-called “last chance respirator” project with the Łukasiewicz Institute, creating a prototype that is easy to build and can be put to use in situations where certified respirators are unavailable.

The Engineers in Arms’ efforts have attracted a good deal of attention on social media. One particular comment on Twitter has raised even more support for their efforts.

“We have been contacted by private companies’ owners as well as other Polish GE sites wanting to dedicate their machines to support us. This would not have happened without Tweets like the one sent by the US Ambassador to Poland. It is a pure honor to have Ms. Georgette Mosbacher supporting our initiative,” said Żochowski.

Solidarity is embedded in the Polish DNA. The collective efforts of Engineers in Arms demonstrate their commitment to helping their community the best way they know how—with guts, compassion and innovation.

“None of the engineers in Engineers in Arms needed convincing to take part in these efforts,” said Żochowski. “We might have different skills and tasks but we all have one purpose as a team. And every day during this tough time, we go to bed happy, knowing that we made a difference.”