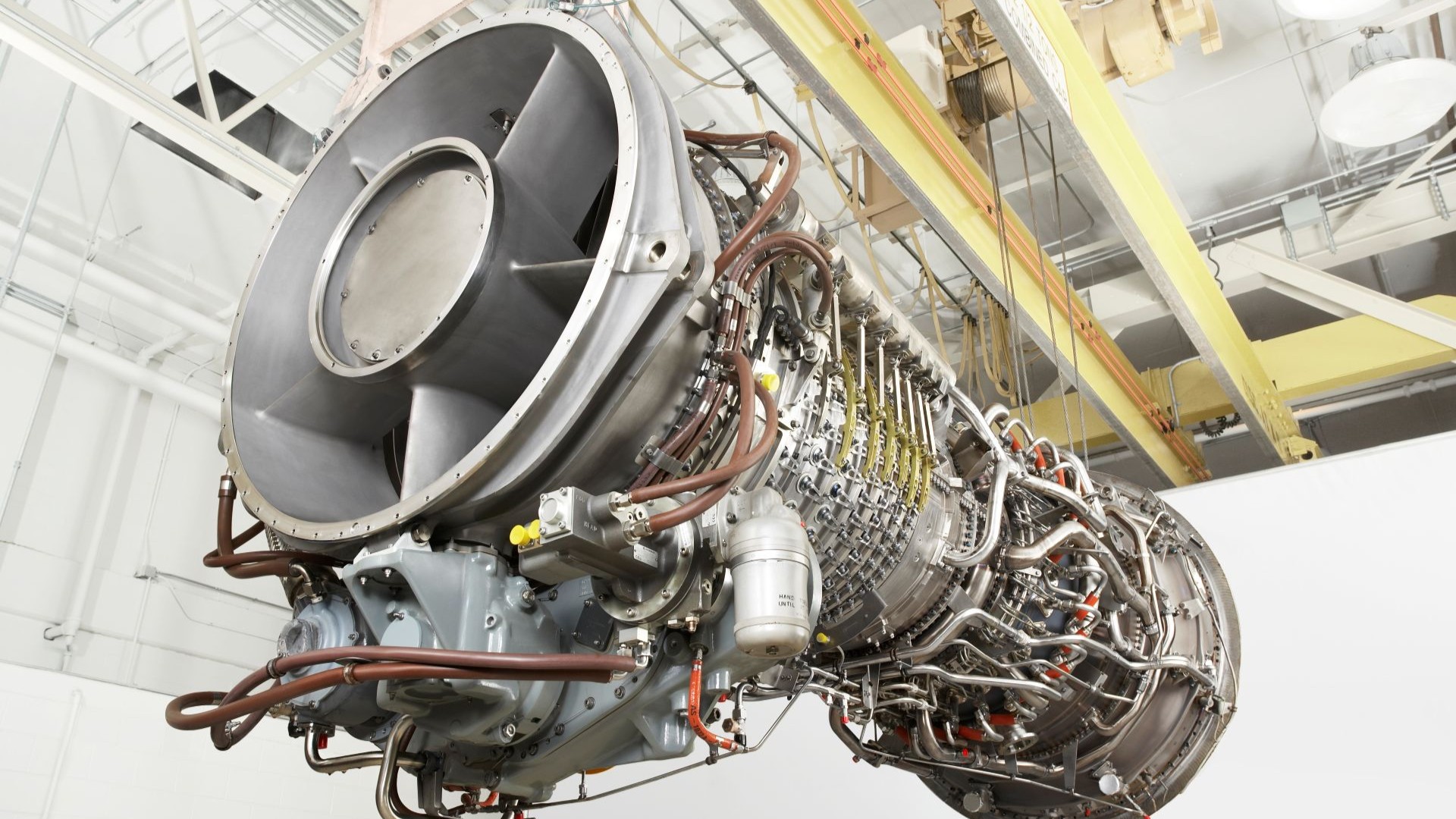

Tested, Tried, and True: GE Aerospace’s LM2500 Continues to Set the Standard in Marine Propulsion

March 24, 2025 | by Cole Massie

Navies around the globe are making plans for their next-generation fleets, and the focus often centers on the propulsion system. Mobility, agility, and reliability are key. These qualities are likely a top priority for the United States Navy as they design a next-generation guided-missile destroyer — part of the DDG(X) program, which will replace its fleet of Ticonderoga cruisers and older Arleigh Burke destroyers. We sat down with Steve Rogers, director of marketing and business development for GE Aerospace’s Marine Engines and Systems business, to discuss how the LM2500 gas turbine engine has continued evolving to meet customer needs.

GE Aerospace Reports: The LM2500 is prolific in naval fleets around the globe. How did that happen? Where does its story begin?

Steve Rogers: About 50 years ago, there was a need identified within the United States Navy for a replacement to its existing steam turbine propulsion plants. GE Aerospace engineers at the time said, We have this great aircraft engine, the CF6, and we think we can make it a competitive gas turbine for marine and industrial applications.

That’s where the LM2500 was born. It’s known as an “aeroderivative” engine, which is exactly what it sounds like — derived from an aircraft engine and built with that same precision. The LM2500 has had an extremely successful run, with more than 16 million naval operation hours. Right now it powers about 95% of the U.S. Navy gas turbine-powered surface combatant fleet.

Since that first version of the LM2500, how has the aeroderivatives team improved it?

Our team really hasn’t rested on its laurels as there have been multiple generations of the LM2500. We’re on the fourth generation right now, which is called the LM2500+G4. Most importantly for our customers, this version provides 33% more power than the original, and still fits within the same footprint on a ship.

It’s an evolutionary product instead of a revolutionary product, which is an attractive proposition to the U.S. Navy. Minimizing program risk is a major objective, and the LM2500 family provides a tested, tried, and true product that has made steady improvements over its lifespan to continue delivering what our customers need. We’ve incorporated advancements in the compressor, coatings, advanced sensors, and fuel controls and introduced a one-piece composite module that’s two and a half tons lighter than its predecessor.

With significant future demand in both the industrial and marine gas turbine segments, that spirit of continuous improvement will go on for decades.

Compared with other propulsion solutions, what differentiates the LM2500?

Reliability is number one. This product has a plus-99% record of reliability across 16 million hours in operation. I hear it directly from our customers: They always have confidence their power will be there when they need it. This goes back to the aeroderivative concept: The fact that the LM2500 is based on an aircraft engine means that it’s built like an aircraft engine. It’s built to run, to tolerate harsh conditions, and to not fail.

Second, I’d highlight the power density. Space and weight are premium attributes for naval architects, and the LM2500 family packs the optimal power density for naval applications. Rather than consuming space and weight for propulsion, it can be used for the advanced weapons systems, sensors, and electronics the U.S. Navy plans to bring aboard the DDG(X) platform.

Maintainability would be my third point. The LM2500 is designed for minimal maintenance, but when required, we’ve introduced a split-case design, very much like a car hood, where our customers don’t need to pull the engine off the ship to take care of it. That means more time fulfilling the ship’s mission.

What does the LM2500’s supply chain look like?

We are very proud that a substantial amount of the LM2500 is manufactured and assembled in the United States. Final assembly takes place at GE Aerospace’s campus in Cincinnati, Ohio.

We have 120 suppliers in 26 states across the U.S., so you have thousands of American jobs connected to LM2500 production. People may not realize it, but Cincinnati is a hub for naval propulsion in the U.S. In addition to many of GE Aerospace’s suppliers, there are many other propulsion-related suppliers in this area.

As a U.S. Navy veteran, can you share what it means to still be involved in the mission?

For many veterans, military service doesn’t end when we leave active duty, and there’s a desire to contribute to our armed forces in whatever way that may be. I find a lot of joy in knowing that what I’m doing is directly supporting our Navy and our allies. There’s a personal connection with our products — the LM2500 is something that sailors are relying on to be effective and employ in combat every day. There’s a huge amount of joy that I get from still being involved in the mission. It’s also rewarding to work with so many veterans, many of whom served in the Navy and have significant experience aboard ships.