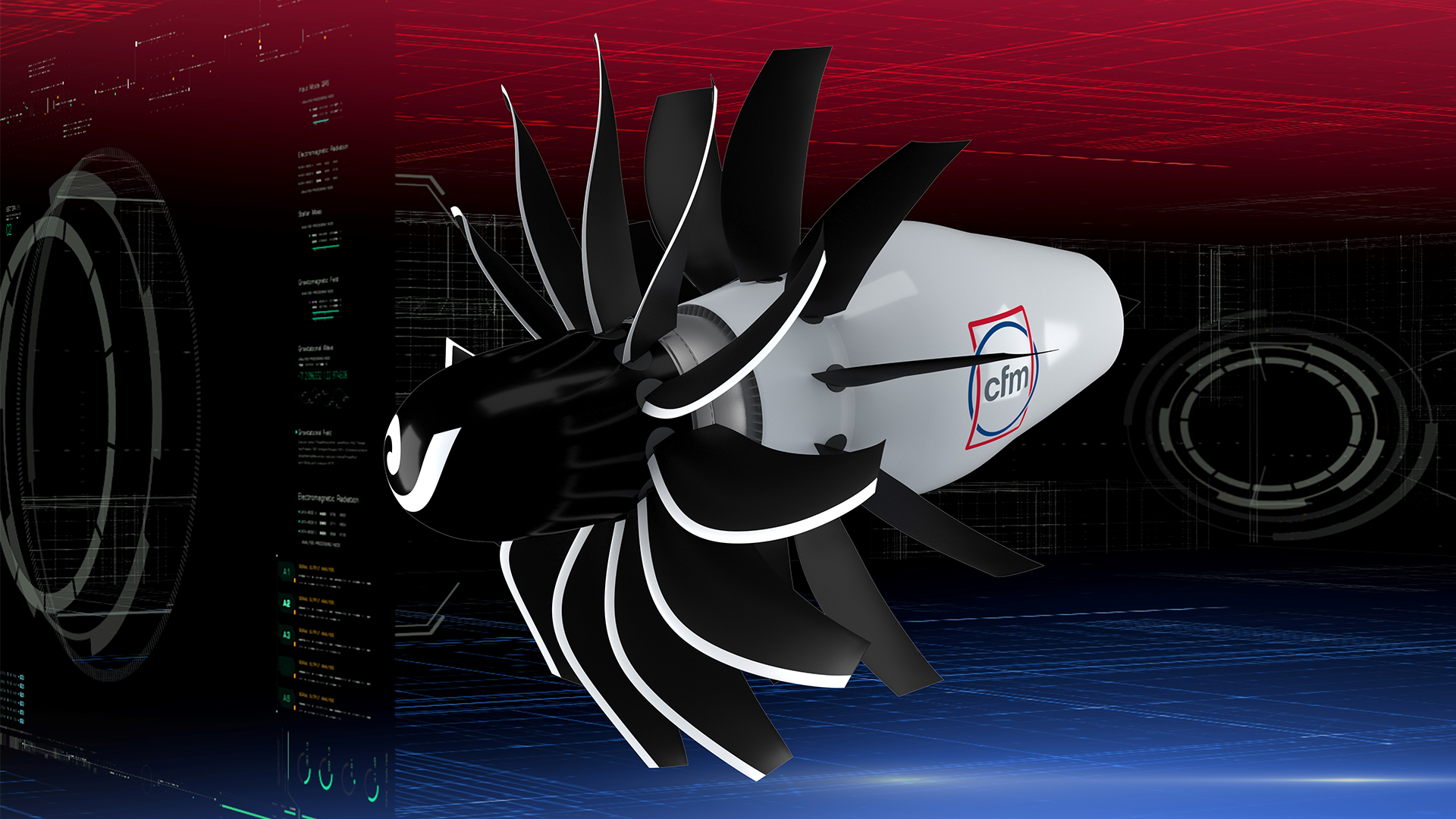

A New Frontier: How GE Aerospace Is Using the World’s Fastest Supercomputer to Help Design an Open Fan Engine for the RISE Program

July 24, 2024 | by Dianna Delling

If every one of the world’s approximately 8 billion people were to complete 60 calculations per minute — arithmetic problems, for example — and continue nonstop, it would take them four years to accomplish what Frontier can do in just one second. Operating since May 2022 at the U.S. Department of Energy’s Oak Ridge National Laboratory in Oak Ridge, Tennessee, the world’s fastest supercomputer can perform more than a quintillion (10 to the 18th power) calculations per second, making it the world’s first exascale machine. It’s billions upon billions of times quicker than the human mind, giving it the power to synthesize and analyze incredibly large quantities of data.

All this makes Frontier an invaluable tool for scientists investigating the most complex questions of our time. And it has been a game changer for GE Aerospace engineers racing to develop the revolutionary Open Fan engine architecture that promises to redefine the future of air travel.

“It has been an exciting experience running these simulations on the world’s fastest supercomputer. This offers a unique view of the detailed turbulence physics of Open Fan as we enable more sustainable aviation for the future,” said Stephan Priebe, a senior engineer specializing in aerodynamics and computational fluid dynamics at the GE Aerospace Research Center in Niskayuna, New York.

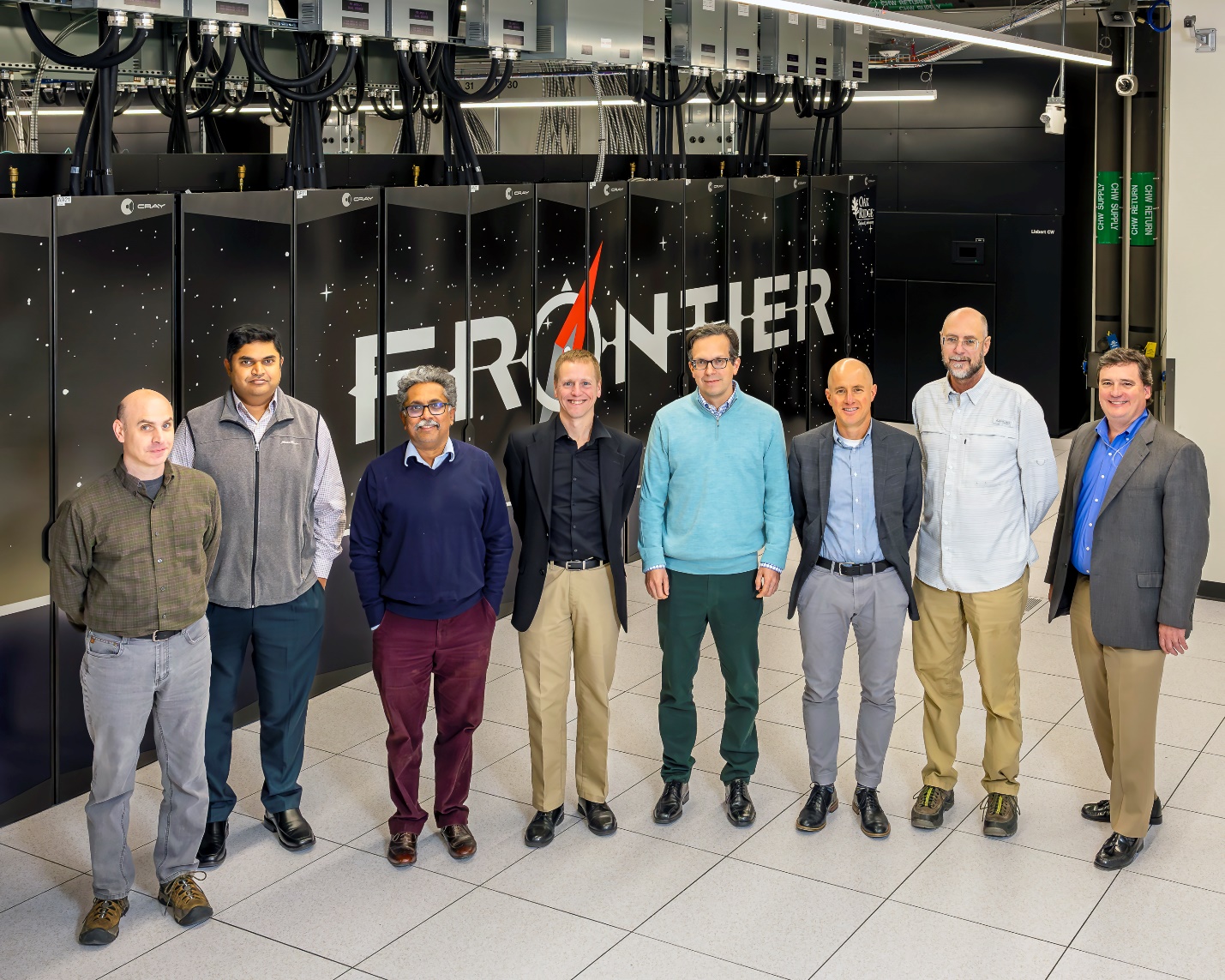

From left to right: Rick Arthur, Umesh Paliath, Sriram Shankaran, Trevor Wood, Alex Simpson, Eric Falk, Peter Schmid, Tim Stone.

Since 2023, when GE Aerospace became the first industrial user granted access to Frontier, they’ve been using it to model engine performance and noise levels. In the process, they’re gaining insights that extend beyond the project at hand.

“Frontier is allowing us to go beyond standard engineering analysis and to do things that were impossible before this machine,” says Trevor Wood, senior principal engineer at the GE Aerospace Research Center. An expert in aerodynamics and aeroacoustics, Wood lends his technical chops to the team designing, running, and analyzing computer simulations on Frontier.

The super-capable computer allows Wood and his colleagues to simulate the full-scale Open Fan engine at actual flight conditions whereas smaller computers can handle only a reduced, scaled-down version. Frontier’s capabilities also allow GE Aerospace engineers to visualize the way air flows around components at a microscopic level. These studies help accurately predict how fan blades will perform in nearly any possible real-life situation, yielding information it would otherwise take scientists years to gather.

“It’s providing us with insights even before we build components and test them on a test stand,” says Eric Falk, executive leader of aerodynamics technology and design at GE Aerospace in Evendale, Ohio. “And harder to put your thumb on is all the intellectual discovery we’re doing in the meantime. The answers we’re getting in these simulations are helping us learn things about aerodynamic behaviors from a deep physics perspective. It’s changing the way we design and changing the way we work.”

Seeing Through the Chaos

GE Aerospace’s Frontier-based projects support the CFM RISE (Revolutionary Innovation for Sustainable Engines) program, unveiled by GE Aerospace and Safran Aircraft Engines in 2021. The RISE program aims to develop technologies that will help enable a future aircraft engine to achieve at least 20% lower fuel consumption and 20% fewer CO2 emissions than today’s most efficient commercial engines.

“When it comes to sustainability, the industry has aggressive goals, including an ambition to achieve net zero by 2050,” says Wood. While the team is testing a variety of RISE program components on Frontier, “we’re running [many] simulations on the fan blade because it’s such a huge driver of net efficiency.”

Simulations pave the way for creating blades that optimize aerodynamic efficiency by reducing sources of energy loss. And they help the GE Aerospace team explore one of the most constantly challenging areas of science: the complex, chaotic flow of air known as turbulence.

Large-scale turbulence creates a bumpiness familiar to anyone who’s flown in a plane. But turbulent air currents are also present at the microscopic level, imperceptible to humans but causing friction, drag, and other issues that affect engine performance and efficiency. Unfortunately, the behavior of turbulent air is notoriously difficult to predict.

“You can’t see turbulence, but simulations can help us visualize it, so we can better understand it,” says Wood.

The level of detail Frontier provides is hard to fathom. “We are simulating air flow while moving forward in time in fractions of a second, getting a read on what the flow field looks like at a scale orders of magnitude less than the width of a human hair off the wall [of the fan blade],” explains Sriram Shankaran, consulting engineer for aerodynamic methods at GE Aerospace. “Turbulence is the last unsolved problem in classical physics. We’re not trying to solve it in a universal way; we’re instead finding ways to compute our way to the solutions we need.”

The Future and Frontier

GE Aerospace’s Frontier simulations have already garnered attention from tech industry insiders. HPCwire, the leading authority in high-performance computing news, commended GE Aerospace in 2023, presenting the company with a Reader’s Choice Award for Best Use of High-Performance Computing (HPC) in Industry and an Editor’s Choice Award for Top Supercomputing Achievement.

Meanwhile, the potential for future Frontier collaborations is growing, with GE Aerospace and Oak Ridge National Laboratory announcing a new Cooperative Research and Development Agreement on supercomputing at the 2024 Farnborough International Airshow this week. GE Aerospace engineers and researchers will continue to use Frontier to study Open Fan engine architecture, and future studies are likely to include climate modeling. “We want to work with Oak Ridge to see how to further accelerate carbon neutrality by understanding how contrails evolve,” says Shankaran.

The organizations will also deepen their relationship with a project that examines how simulations are conducted, looking for ways to improve simulation monitoring and data analysis. “We are taking it to the next level, leveraging the deep expertise the Oak Ridge team has developed to make our processes more efficient from a software perspective,” says Umesh Paliath, technology manager for aerodynamics and computational fluid dynamics at GE Aerospace Research. “How can we get the most out of the data once a simulation is done, and while it’s running?”

Paliath oversees the company’s partnership with Oak Ridge, and he leads the team that develops GE Aerospace’s in-house software so it can be used to run simulations on Frontier. Part of his job is keeping up with supercomputing’s evolving capabilities, ensuring that GE Aerospace is always ready to take full advantage of them.

“Advancements in computing architecture are enabling significantly faster and larger simulations of the most challenging problems in science,” says Paliath. “What takes a month to do today will only take a day, and it will happen incredibly soon.”