Move Fast and Fix Things: How GE Aerospace’s On Wing Support Team Is Using FLIGHT DECK to Repair CFM LEAP Engines Quicker

January 27, 2025 | by Christine Gibson

Your phone rings — it’s the garage where you dropped off your car for repairs this morning. Bad news: The transmission is shot. Your heart sinks. Your schedule is packed. There’s no time for your vehicle to be stuck in the shop.

If it’s a tough situation for a driver, it’s even harder for an airline, which has to keep critical operations running while ensuring the entire fleet is in top condition. But if the vehicle in question is a jet powered by GE Aerospace, Engine Alliance, or CFM International engines, GE Aerospace’s On Wing Support (OWS) is often an airline’s first call. With seven repair stations across the globe — in Shanghai, Seoul, Doha, Dubai, London, Cincinnati, and Dallas — OWS offers 24/7 support. Depending on the urgency and level of repair needed, team members can work on engines in the shop (off-wing) while others are in the field, performing quick-turn services for engines still installed on aircraft (on-wing).

Over the past few years, CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines, has boosted production of its LEAP engine to the highest rate ever for a commercial turbofan. As more LEAP engines have entered service, OWS has focused on streamlining the process for a high-pressure turbine (HPT) refresh, a common off-wing repair in which the complex combustor and turbine parts in the heart of the engine can be refurbished or replaced.

It’s a problem seemingly custom-made for FLIGHT DECK, GE Aerospace’s proprietary lean operating model. One of FLIGHT DECK’s fundamentals is continuous improvement, achieved with the help of kaizen events, multiday events during which participants hunt for ways to eliminate waste and increase efficiency. In June 2023, staff members from every OWS site gathered alongside global technical and operational leadership, as well as their partners, to redesign their HPT refresh procedures. The results: a 170% increase in capacity — opening space to service 41 additional engines — by the last quarter of 2024. Network-wide, LEAP output at OWS grew by more than 60% over the course of the year.

We talked to Jonathan Hill, senior FLIGHT DECK operations leader at CFM Programs; Alex Henderson, general manager for OWS at GE Aerospace; and Andy Nader, OWS’s global delivery leader, about achieving flow, getting buy-in, and where they’re activating FLIGHT DECK next.

What prompted the team to drive improvements across the OWS network?

Andy Nader: With the number of LEAP engines out in the field, we knew we needed to get ready for what was coming.

Jonathan Hill: The question was, how could we maximize the On Wing Support footprint we already had?

Alex Henderson: Even though LEAP has been in service for eight years, the intense ramp on the MRO network has happened over the past two to three years. COVID suppressed demand, but it’s recovering rapidly. Some of our on-wing sites have also added LEAP as a new product. We were keen to make sure that those sites were optimized from day zero. As the network grows, you get dividends from being early.

What sort of work goes into a kaizen event?

Henderson: The bulk of the effort isn’t during the kaizen itself. Yes, the week is intense, but we do 10 times as much work gathering all the data and references the teams will need ahead of time, so that when they come together they’re set up for success. That’s why the whole process took a year and a half to execute.

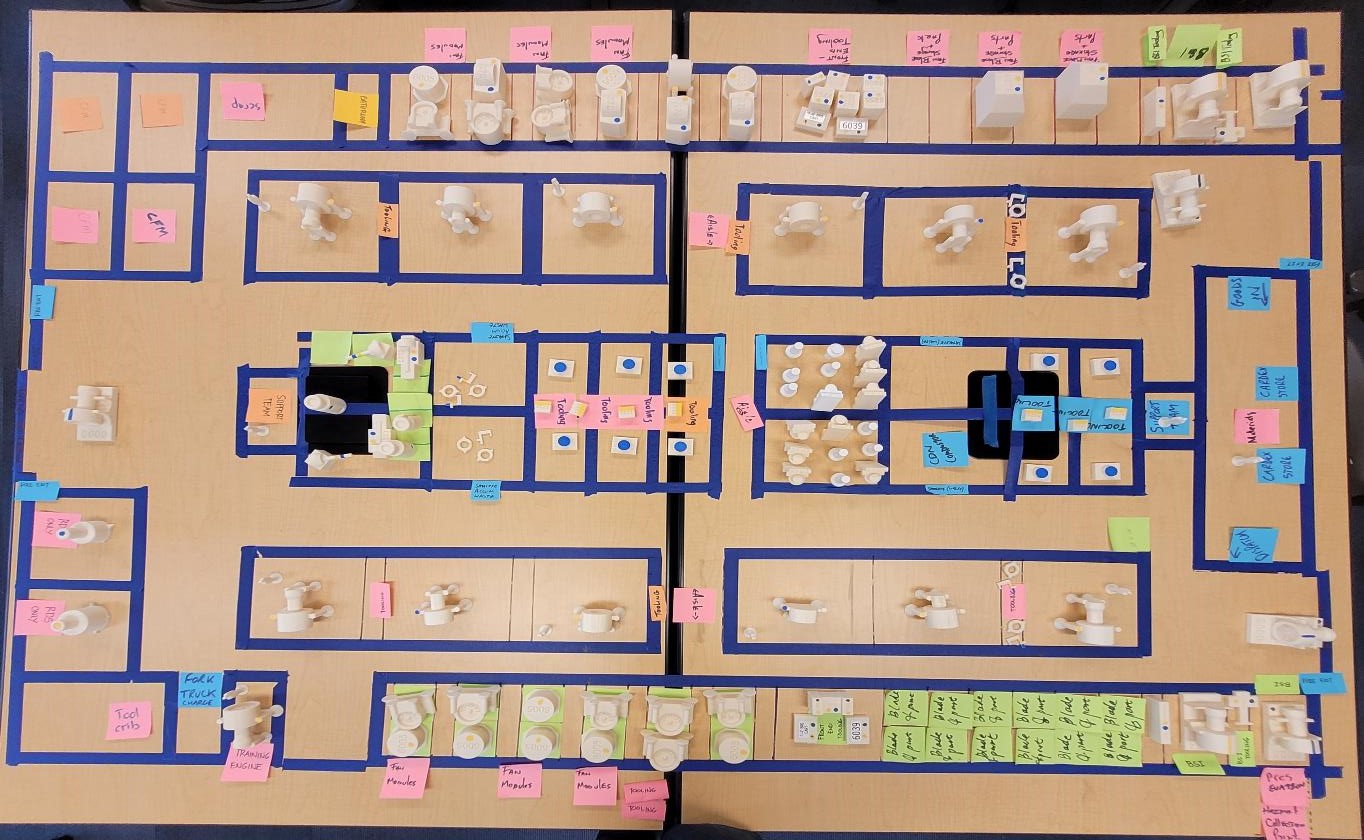

Hill: It gets down to the nitty-gritty of ensuring we have tape to put on the shop floor, and facilities management teams are available to pull down racking. We even had 3D-printed scale models made of each shop and the LEAP engine parts, so we could visualize everything more easily.

Can you walk me through how a kaizen works?

Hill: A kaizen event typically starts on a Monday and runs through Friday. On Monday we try to understand why we’re all together and what impact we need to make. We’re bringing everyone on board and assessing our current state.

On the second day, we break the team into groups and challenge each group to come up with seven different solutions. We score the ideas on safety, quality, delivery, and cost, in that order of importance. By the end of the third day we’ve got a pretty good understanding of what’s going to work best. In the final days we start to finalize and implement some of the changes to establish our future state.

So when you score the ideas, safety is always the most important?

Hill: Yes, safety is always top of mind. Before we even start, we make sure we have risk assessments in place for any changes we might make.

Nader: A lot of it is proactive: Here’s a sharp part of the engine sticking out where it didn’t used to be — put a cover on that. We moved this desk over here, and now this cord is a trip hazard — get it out of the way. Putting safety first reaffirms the culture for our technicians.

Hill: We made 60 safety and quality improvements through this process, and we disseminated them to all the sites, so those technicians can go home safe as well.

How do you get buy-in from the local teams?

Hill: Respect and listening, especially to the members who are closest to the work — the technicians. If we had said, “All right, everyone, we’ve got to ship more engines; management has sat in a corner and decided this is how to do it,” we wouldn’t have made the same impact.

Nader: The more the technicians take the lead, the better the results. Our technicians know the right way to do things. If we support and listen to them, they’ll find it.

What did you discover through the kaizen?

Henderson: The first session with the whole team in Cincinnati laid out the template for each of the sites. We moved from what we called the fixed-bay method, which had been the hallmark of On Wing Support operations, to a new flow-based style.

Hill: On Wing Support performs surgical maintenance. Rather than strip out every single component, we take out one part or one module.

Nader: It used to be like an emergency room. An engine would come into a bay, and we would do very targeted surgery on whatever part had to be removed. Then we would send that out for repair.

Hill: Which could take 40 to 60 days.

Nader: Meanwhile, the rest of the engine is just sitting in that emergency room bed, taking up space.

Hill: In a lean system, waiting is one of the key wastes to eradicate. If you’ve got engines just sitting somewhere, you can’t use that footprint.

Nader: Now, once we’ve removed the parts that need to be fixed, we put the rest of the engine in storage. Get it out of that valuable space and bring the next engine in.

Hill: By implementing elements of flow — meaning the work proceeds continuously and consistently — we can use our footprints much more efficiently.

Henderson: What surprised me was the scale of the optimization that was possible. It almost doubled the capacity of our existing footprint.

Now that you’ve completed the kaizen event, how do all the sites stay connected?

Hill: We’ve focused on creating standard work among the On Wing Support shops. All of the facilities now have the same clear-cut procedure for LEAP HPT refreshes.

Henderson: It helps the teams share — when we learn something new, it’s in seven places, rather than one or two. And it wouldn’t have been possible if we hadn’t created the global standard for flow and facility layout first.

Did you learn anything new about FLIGHT DECK?

Henderson: The biggest highlight for me was the power of continuous improvement: learning as much from the experience as we could, improving our operating model, setting us up for the future.

Nader: It feels like it’s exponentially continuous. The more kaizens we do, the more people there are who know how to do it, who can teach someone else. It just keeps going.

As the LEAP ramp-up continues, how is this going to help you meet your customers’ needs?

Nader: Every customer appreciates getting their engines back faster. They want it sooner and in top-quality condition. This process achieves both.

Henderson: The great thing is we identified other possible improvements during the process, which gives us a road map for future refinements and enhancements.

Nader: There’s a momentum behind the kaizen approach. As people see results, buy-in gets easier, and the process gets more powerful. We’re just at the beginning.