Two of GE Aviation’s new U.S. factories in Lafayette, Indiana; and Asheville, North Carolina; were recently part of media events highlighting the innovative technologies at both operations.

The Lafayette plant, opened in 2016, assembles the LEAP engine for CFM International, the 50/50 joint company of GE and Safran Aircraft Engines of France.

The Lafayette event was part of GE Corporate’s “Brilliant Manufacturing Showcase” tour in which national and local media learned about GE’s commitment to equip employees with skillsets needed to fill today’s advanced jobs on the factory floor.

At the event, Colleen Athens, vice president and GM of GE Aviation’s Supply Chain, described the $4.3 billion investment in five years by GE Aviation in its U.S. operations. Lafayette and Asheville are two of eight new U.S. factories built by GE Aviation in the past eight years.

With a backlog of about 12,000 LEAP engines slated for delivery in the next five years across three GE and Safran sites, including Lafayette, GE Aviation “is in the Hoosier state (Indiana) for the long haul,” Athans said.

“Meeting our record production rates on this new family of engines is particularly challenging because of the exciting new technologies they contain,” she said. “These state-of-the-art designs and new material systems require cutting edge manufacturing processes.”

Reporters and civic leaders saw Colleen’s words in action in Lafayette with several manufacturing advances installed in the plant such as automation and robotics, assembly techniques, and unique inspection capabilities.

Workforce training was a key portion of Colleen’s discussion with the local group. At 13 of GE Aviation’s U.S. factories are apprenticeship programs through partnerships with 14 technical schools. In Lafayette, the company has pipeline programs with nearby Ivy Tech Community College and with Purdue University.

From a recruiting standpoint, Purdue consistently ranks #1 or #2 in terms of engineering graduates hired by GE businesses.

For GE Aviation’s new Lafayette plant, Purdue has partnered with Ivy Tech to provide training for FAA airframe and power plant licenses. Ivy Tech also trains in aviation maintenance.

Employment at the Lafayette plant has grown to about 75, but will swell to more than 230 people at full production.

The event concluded with a tour by plant manager Eric Matteson who organized much of the day’s activities.

At Asheville, GE Aviation’s site leader Michael Meguiar hosted the media on a tour and discussion of one of the most unique factories in jet propulsion. The Asheville operation produces ceramic matrix composite (CMC) parts for GE and CFM engines.

It is part of the vertically integrated CMC supply-chain network being established by GE Aviation in the U.S. with sites in Asheville, Cincinnati, Ohio; Huntington, Alabama; and Newark, Delaware.

GE Aviation’s Human Relations leader at Asheville, Sarah Dunn, discussed with the local media our workforce relationships with AB Tech and Pisgah High School to prepare workers in the sophisticated process of fabricating CMC parts.

Meguiar then highlighted GE’s $125 million investment in the Asheville with a walk-through on the shop floor. Asheville is scaling up to meet the ramp requirements for the best-selling LEAP engine as well as for our latest military products.

Take a 360-degree tour of GE Aviation’s brilliant factory in Asheville, North Carolina:

https://www.youtube.com/watch?v=u6rx9b_EBKw&feature=youtu.be

The Lafayette plant, opened in 2016, assembles the LEAP engine for CFM International, the 50/50 joint company of GE and Safran Aircraft Engines of France.

The Lafayette event was part of GE Corporate’s “Brilliant Manufacturing Showcase” tour in which national and local media learned about GE’s commitment to equip employees with skillsets needed to fill today’s advanced jobs on the factory floor.

At the event, Colleen Athens, vice president and GM of GE Aviation’s Supply Chain, described the $4.3 billion investment in five years by GE Aviation in its U.S. operations. Lafayette and Asheville are two of eight new U.S. factories built by GE Aviation in the past eight years.

With a backlog of about 12,000 LEAP engines slated for delivery in the next five years across three GE and Safran sites, including Lafayette, GE Aviation “is in the Hoosier state (Indiana) for the long haul,” Athans said.

“Meeting our record production rates on this new family of engines is particularly challenging because of the exciting new technologies they contain,” she said. “These state-of-the-art designs and new material systems require cutting edge manufacturing processes.”

Reporters and civic leaders saw Colleen’s words in action in Lafayette with several manufacturing advances installed in the plant such as automation and robotics, assembly techniques, and unique inspection capabilities.

Workforce training was a key portion of Colleen’s discussion with the local group. At 13 of GE Aviation’s U.S. factories are apprenticeship programs through partnerships with 14 technical schools. In Lafayette, the company has pipeline programs with nearby Ivy Tech Community College and with Purdue University.

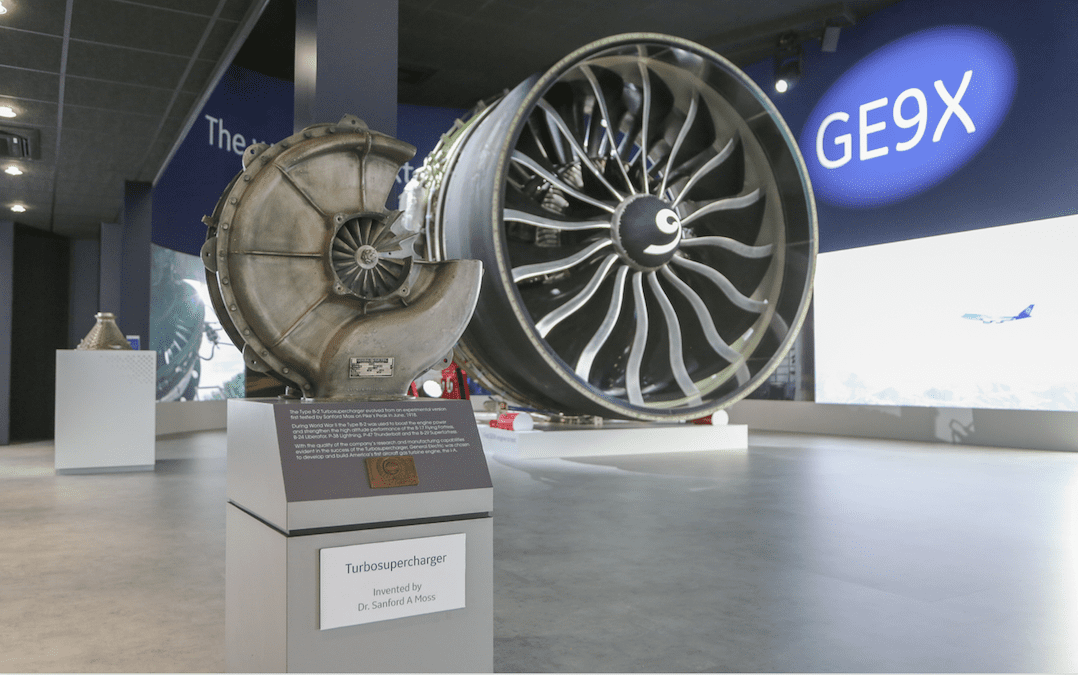

A peek at GE Aviation's brilliant factory in Lafayette, Indiana.

A peek at GE Aviation's brilliant factory in Lafayette, Indiana.

From a recruiting standpoint, Purdue consistently ranks #1 or #2 in terms of engineering graduates hired by GE businesses.

For GE Aviation’s new Lafayette plant, Purdue has partnered with Ivy Tech to provide training for FAA airframe and power plant licenses. Ivy Tech also trains in aviation maintenance.

Employment at the Lafayette plant has grown to about 75, but will swell to more than 230 people at full production.

The event concluded with a tour by plant manager Eric Matteson who organized much of the day’s activities.

At Asheville, GE Aviation’s site leader Michael Meguiar hosted the media on a tour and discussion of one of the most unique factories in jet propulsion. The Asheville operation produces ceramic matrix composite (CMC) parts for GE and CFM engines.

It is part of the vertically integrated CMC supply-chain network being established by GE Aviation in the U.S. with sites in Asheville, Cincinnati, Ohio; Huntington, Alabama; and Newark, Delaware.

GE Aviation’s Human Relations leader at Asheville, Sarah Dunn, discussed with the local media our workforce relationships with AB Tech and Pisgah High School to prepare workers in the sophisticated process of fabricating CMC parts.

Meguiar then highlighted GE’s $125 million investment in the Asheville with a walk-through on the shop floor. Asheville is scaling up to meet the ramp requirements for the best-selling LEAP engine as well as for our latest military products.

Take a 360-degree tour of GE Aviation’s brilliant factory in Asheville, North Carolina:

https://www.youtube.com/watch?v=u6rx9b_EBKw&feature=youtu.be