In Amsterdam’s Rijksmuseum, a high-tech radiographic scanner moves slowly over every millimeter of Rembrandt’s largest and most well-known work, “The Night Watch.” Created in 1642, the painting is a treasure from the Dutch Golden Age, and this analysis will provide a detailed look at the chemical composition of the work’s many layers without ever penetrating its fragile surface. Once complete, the scan will help curators understand the materials and process Rembrandt used, shedding light on the best ways to restore and preserve the painting.

Soon the same technology that’s aiding museums and art restorers — known as open-beam micro X-ray fluorescence (XRF) spectrometry — will help GE Aerospace inspection teams learn more about masterpieces of their own. Working in partnership with Bruker, the Massachusetts-based materials analysis company that created the XRF scanners used by the Rijksmuseum, GE Aerospace has developed a new nondestructive process for examining engine components at the microstructural level. “It offers a way to perform chemistry analysis on the surface of components that we don’t otherwise have,” says Joseph Traxler, manager of nondestructive evaluation for field maintenance, repair, and overhaul (MRO) at GE Aerospace.

A first in the aviation industry, GE Aerospace’s XRF process will enable engineers to more quickly and effectively detect variations in the composition of metal parts that come in for inspection, and make more informed decisions about whether the parts are airworthy or need to be replaced. Potential problems can be diagnosed at their earliest possible stages, a big plus for ensuring safety. At the same time, by more definitively confirming that a component is fit to fly, the process can help avoid unnecessary part replacements, potentially saving aircraft operators money and helping to ease supply chain issues confronting the industry.

Traxler is no stranger to using advanced imaging techniques on airplane engine components. At the GE Aerospace Inspection Solutions laboratories in Cincinnati, he and his team work with various types of ultrasound, computed tomography (CT), and other diagnostic technologies similar to those used in medical facilities. A prototype of the new XRF inspection device was developed in his lab, and production-ready versions will be introduced at GE Aerospace’s Services Technology Acceleration Center (STAC) when it opens in September.

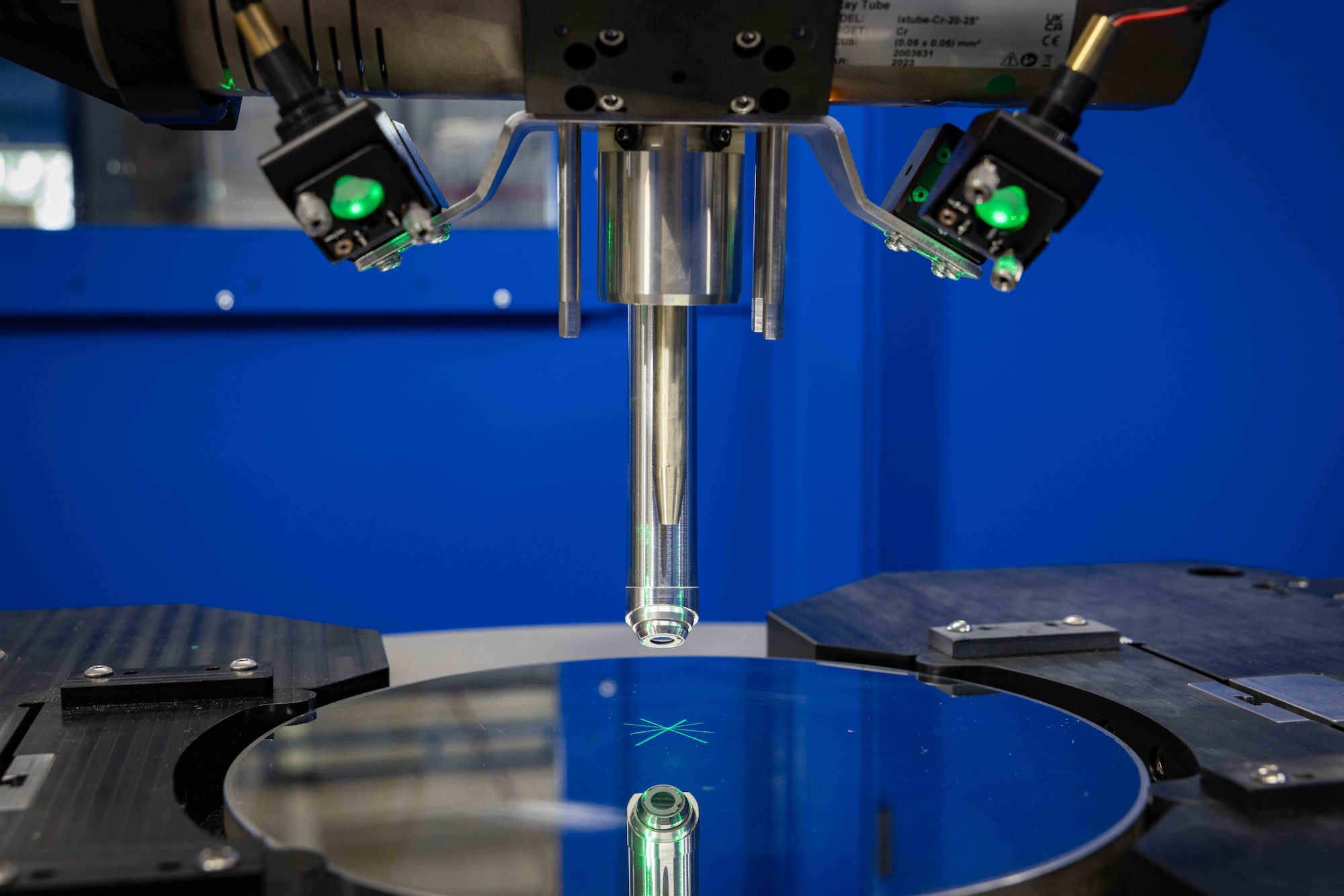

XRF technology will initially be used to evaluate rotating metallic parts that come in for service or refurbishing — turbine blades and other rotating parts such as fan disks or spools, for example, which have been regularly exposed to extremes in temperature, air pressure, and weather conditions, along with other routine wear and tear. In testing, Traxler explains, “the part is spinning while our XRF column, pinpointed to look at a very, very small area, slowly moves over it and indexes it. We take data 360 degrees around the part, covering the entire surface.”

To get the idea, picture the needle on a phonograph slowly moving across the entire surface of a spinning vinyl record — except in this case, the scanning device never touches the part directly. Instead, the scanner’s head emits X-rays that bounce off atoms on the component’s surface and produce fluorescence that varies in pattern and wavelength depending on the type of materials they hit. The results of the scan are analyzed and used to create a detailed image of the component, which engineers then use to evaluate qualitative aspects of the materials that help them assess its fitness for service.

“With the new XRF technology we’ve developed in partnership with Bruker, we’re inspecting metal jet engine parts at the same level of forensic detail museums and auction houses use to identify forged pieces of artwork,” says Nicole Jenkins, chief MRO engineer at GE Aerospace. “This new inspection technology will allow us to be even more vigilant with verifying the integrity of metal parts.”

The XRF system for part-level serviceability inspection will initially be available only at STAC. But handheld units are currently being used on a trial basis to do nondestructive analysis of foreign debris, confirm parent metal compositions, and look for trace-level impurities in the supplies and materials used to perform maintenance tasks at GE Aerospace’s overhaul facilities in Brazil and Wales. Traxler notes that XRF technology also has the potential to help with inspections of components at the manufacturing stage, well before engines are mounted on airplane wings. “Once developed,” he says, “it becomes a tool in my toolbox that can be used for other problems in the field.”

“The opening of STAC, along with the introduction of this new XRF process, demonstrates the additional rigor we’re putting behind the development and deployment of new technologies that increase efficiency and keep the focus on safety,” says Traxler. One might even say, with a nod to the Old Masters, it signals a Renaissance period for innovation.