Just Win Baby! Lynn Turboshaft Engines Team Has Storied History of Winning

February 21, 2019 | by Rick Kennedy

Earlier this month, the U.S. Army selected the GE Lynn turboshaft engine team’s T901-GE-900 for the competitive Improved Turbine Engine Program (ITEP) to re-engine its massive fleets of Apache and Black Hawk helicopters.

This was a huge strategic victory for GE. All the more remarkable, the Lynn team has held its winning tradition for seven decades – preceding the formation of the New England (originally “Boston”) Patriots by many years.

The T901 joins GE’s T58, T64, T700, and T408 turboshaft engine families in providing horsepower for generations of helicopters. The Lynn team has a record hard to match.

A look at some of the big turboshaft wins:

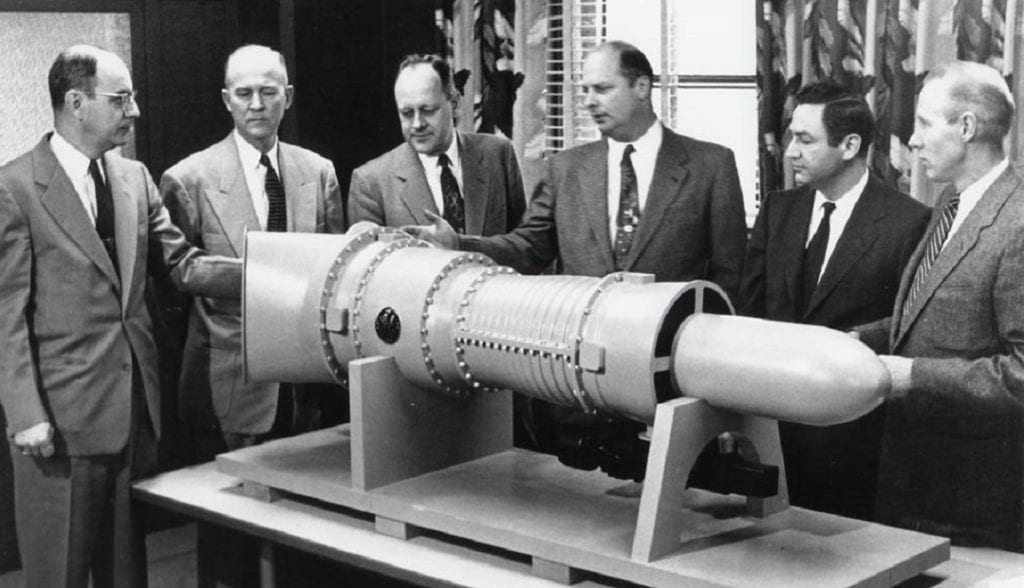

The T58 project team (from left to right) of Les Asher, Larry Callahan, John Turner, Jack Parker, Ed Woll and Harold Hokanson helped create a "baby gas turbine."

The T58 project team (from left to right) of Les Asher, Larry Callahan, John Turner, Jack Parker, Ed Woll and Harold Hokanson helped create a "baby gas turbine."

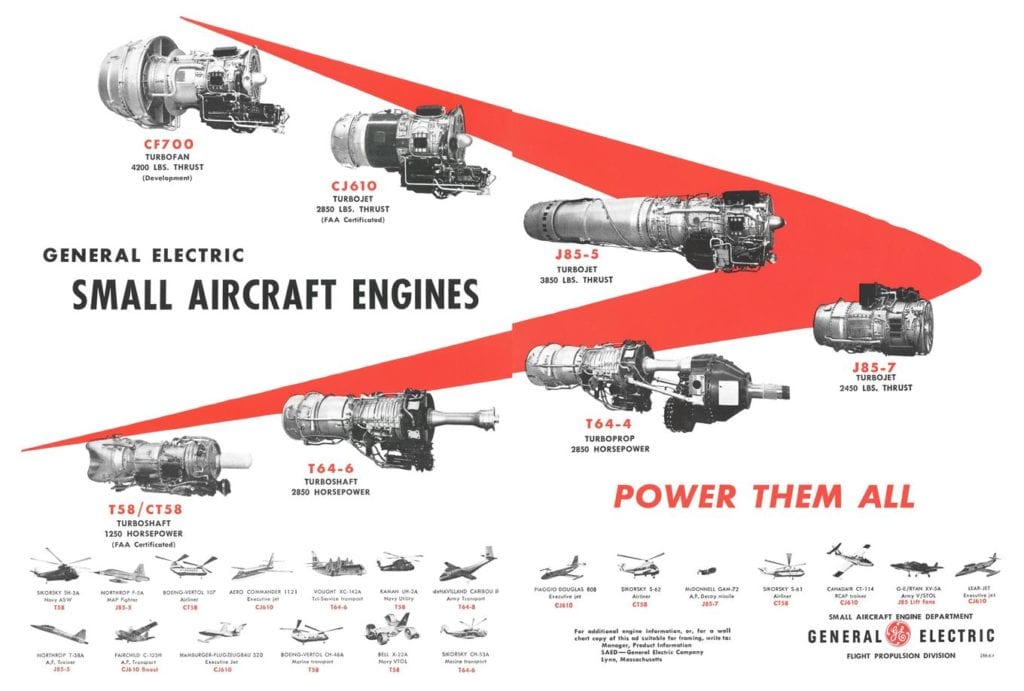

T58: This turboshaft engine prowess began in 1954. The young GE Aviation enterprise, facing competitive pressures from Pratt & Whitney, established the “Committee for Aviation Strategy” to create a technology roadmap for growing the overall business. Jack Steele Parker, a 35-year-old GE manager, headed the committee.

In addition to a fighter turbojet strategy, the committee created the Small Aircraft Engine Division in Lynn. As Parker said at the time: GE will introduce a “baby gas turbine” the size of the family automobile engine but six to eight times as powerful.

That engine, the T58, weighed 250 pounds and produced 1,050 shaft horsepower, a remarkable achievement. “We thought gas turbines of lower power could be very profitably and efficiently employed in a lot of aircraft,” the late Parker recalled. First deployed with the U.S. Navy, the T58 helped to make piston-powered helicopters obsolete. In addition, GE’s first commercial aviation customers were operators of T58 powered civil helicopters. The T58 was the first turbine engine certified by the FAA for civil helicopter use.

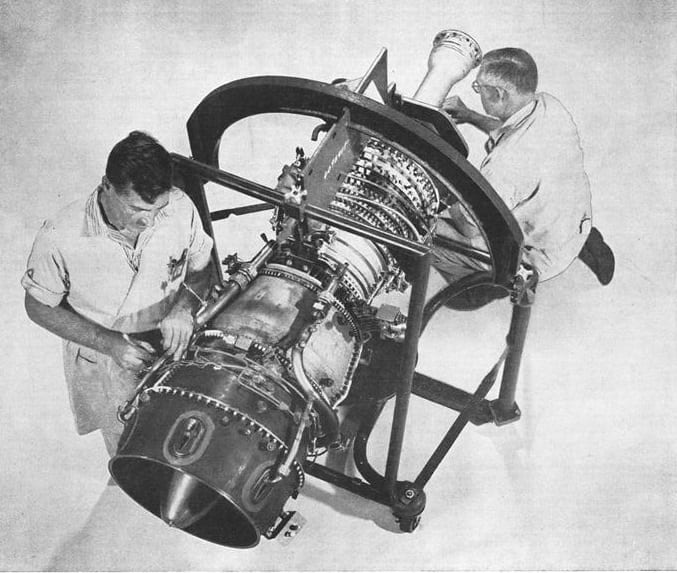

GE introduced the T64 engine for helicopters but it later found its way onto fixed-wing aircraft.

GE introduced the T64 engine for helicopters but it later found its way onto fixed-wing aircraft.

T64: Four years later, T58 breakthroughs fueled the U.S. Navy’s appetite for more turboshaft power. The Navy awarded a contract for a larger engine in the 2,600-horsepower class. The contract was touted as the first for two types of engines with the same core “hot section” (compressor, combustor, turbine).

The T64 was the also GE’s first front drive engine. This coaxial shaft design paved the way for future turbofan engines. The Navy launched T64 turboshaft and turboprop variants for helicopters, transports, and support aircraft. More than a half-century later, the T64 powers aircraft every day.

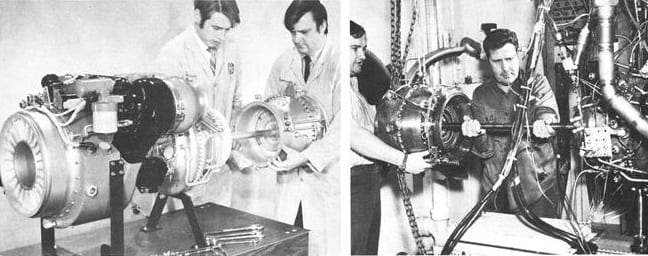

Developed in response to the United States Army’s requirement to deliver added power and improved field maintainability, 20,000 T700/CT7 engines have now surpassed 100 million flight hours in nearly four decades of service.

Developed in response to the United States Army’s requirement to deliver added power and improved field maintainability, 20,000 T700/CT7 engines have now surpassed 100 million flight hours in nearly four decades of service.

T700: By 1967, the helicopter landscape changed. With the Vietnam War, military helicopters assumed major roles both as combat vehicles and as troop transports in hostile environments. With U.S. government seed money, studies commence on the GE12 demonstrator.

The GE12 design was nothing short of revolutionary: the first axial-centrifugal (impeller) compressor. The first stages are axial with compressed air moving parallel to the engine centerline to the centrifugal stage, where the impeller spins compressed air from the center toward the outside.

In 1972, the U.S. Army launched a production version of the GE12 called the T700, which would become the most popular turboshaft engine for military and civil helicopters for more than a half-century. The T700 set a milestone as one of the most-produced engine families in aviation history.

The T408 gives the CH-53K King Stallion helicopter the power to carry a 27,000-pound external load over a mission radius of 110 nautical miles in hot weather conditions, nearly triple the external load carrying capacity of current aircraft.

The T408 gives the CH-53K King Stallion helicopter the power to carry a 27,000-pound external load over a mission radius of 110 nautical miles in hot weather conditions, nearly triple the external load carrying capacity of current aircraft.

T408: As T700 turboshaft and turboprop (CT7) applications expanded over the decades, the Lynn team focused on a higher horsepower class. In 2007, Sikorsky Aircraft selected the T408 (originally called the GE38) for the U.S. Marine Corps' three-engine CH-53K heavy-lift helicopter, which replaced the venerable T64-powered CH-53E.

The T408 was another GE example of how focused technology efforts can bear fruit decades into the future. The engine’s core was based on the GE27 demonstrator first developed in the 1980s and upgraded on the CFE738 turbofan for the Dassault Falcon 2000 and the T407 turboprop for the US Navy P-7(a program later cancelled).

However, the T408 is not your father’s GE27 demonstrator. Significant material and design improvements enable higher turbine efficiencies and operating temperatures. “We started with a mature core and incorporated several new technologies, including GEnx turbine blade cooling schemes,” said Harry Nahatis, GE’s general manager of turboshaft engines. With GE’s commercial and military R&D investments, the T408 was developed at half the cost of a new turboshaft engine, Nahatis said.

The T408 is similar in size to the T64 but produces 57 percent more power with 63 percent fewer parts. The parts reduction is achieved through a blisk structure and fewer compressor stages. The Full Authority Digital Engine Control (FADEC) automates several control and monitoring functions to reduce parts.

The T408 was an immediate success story on the CH-53K, accumulating more than 7,500 hours at the onset without a single, unscheduled engine removal. The program will be a significant source of revenue for the Lynn turboshaft operation well beyond 2020 as new applications arise.

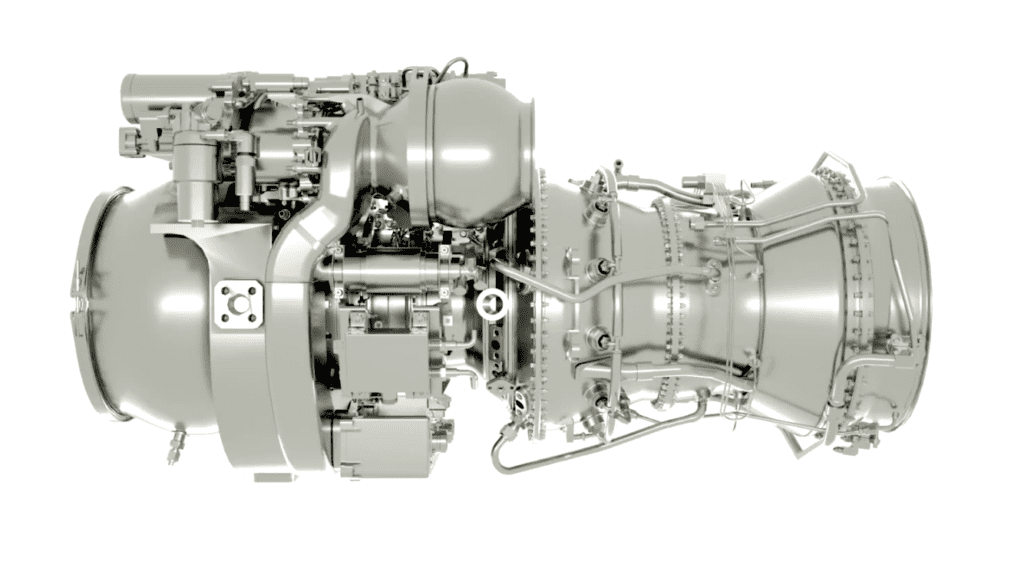

GE stands ready to take the U.S. Army into the future of rotorcraft aviation with its T901 engine.

GE stands ready to take the U.S. Army into the future of rotorcraft aviation with its T901 engine.

T901: By the second decade of the 21st century, the Lynn team was in the throes of developing an engine to ultimately replace the wildly successful T700 engine. In December of 2009, the U.S. Army launched the Improved Turbine Engine Program (ITEP) to seek a new turboshaft engine to provide 50% more power, 25% better specific fuel consumption while reducing life cycle costs. GE carried over the benefits of the T700 engine’s single-spool core architecture to the T901 engine. Like its predecessors, the T901 is incorporated with advanced ideas and technology.

The T901 includes additive manufacturing, including one part that reduces an assembly of more than 50 subcomponents to just one. It also includes 3D aerodynamic design, advanced cooling technologies and ceramic matrix composites (CMCs) to make the engine more efficient and reduce fuel consumption.

Sixty-five years on, the late Jack Parker would be amazed!