ABCs of Aviation: Technology and Engineering Milestones From the First 100 Years of GE Aviation

April 2, 2019 | by GE Aviation News Staff

GE Aviation has been inventing the future of flight for the last 100-years. To celebrate, we counted down the ABCs of Aviation, highlighting the technology and engineering milestones that have made our first 100 years remarkable. These are the aviation-themed words we've all come to know and love. If you have a word you think is more significant, let us know!

A is for Adaptive Cycle — Whether the military pilot’s mission is fuel efficiency or high thrust, GE Aviation’s Adaptive Cycle Engine allows them to automatically switch between engine modes in the air and on the move. Traditional engines have fixed air flow. The Adaptive Cycle Engine is the only combat engine with variable cycles, able to withstand longer flight times and the hottest temperatures for engine parts in the history of jet engine propulsion.

B is for Bypass Ratio — Bypass Ratio measures airflow through a turbofan jet engine, comparing how much air goes around the engine core than through the engine core. Engines with high bypass ratios generate more thrust for less fuel. The GEnx engine gained 15 percent fuel efficiency over the CF6 engine, thanks in part to new lightweight material technologies and a bypass ratio as high as 8.3 for certain models.

C is for Ceramic Matrix Composites — Jet engines powering flight are now made with new materials such as Ceramic Matrix Composites (CMCs), which is replacing some metals in hot sections of more GE Aviation engines. Composites consist of separate materials that, when joined together, have new properties. In the case of CMCs produced by GE, the materials are stronger and can withstand higher temperatures compared to some metal alloys, leading to lighter, more fuel efficient, yet more powerful engine products. Watch and see how these super materials are created.

D is for Data Visualization — GE Aviation’s Digital Solutions help customers understand data and analytics to solve business challenges. For example, the GE Data Visualization project allows airlines to gain valuable insight from large volumes of flight and operations data to help prevent disruptions and identify revenue-growing opportunities.

E is for Electron Beam — Using a 3D printer, layers of titanium aluminide powder are welded together with a 3-kilowatt electron beam to make turbine blades for the GE9X engine. Electron Beam melting can be used to make parts with complicated shapes that weigh less than parts made with traditional manufacturing methods such as casting.

F is for FlightPulse — Not only are technologies such as additive manufacturing and composite materials being used to make lighter weight and more fuel-efficient jet engines, data can also reduce fuel consumption on aircraft. Collaborating with pilots, GE Aviation developed FlightPulse, an application allowing pilots to measure fuel use during every stage of a flight. Pilots can use their findings to make fuel-saving changes on their next trip.

G is for Gas Turbine — At the very heart of the jet engine powerplant is the gas turbine. Early generators mostly used steam, but in 1903, a young engineer named Sanford Moss hit on an idea to produce power by using a small turbine wheel driven by exhaust gases to turn a supercharger. Using this concept at General Electric’s Steam Turbine Department in Lynn, Mass, Moss perfected his supercharger design for aviation, enabling airplane engines to retain their power at high altitude by feeding thicker exhaust air back into the engine. In 1942, Moss used his turbine principals to help GE develop the first practical jet engine, the I-A. Today, the gas turbine is one of the most widely used forms of propulsion systems for modern aircraft engines.

H is for Hush Hush Boys — With WWII raging in Europe, the British aircraft industry was frantically building fighter planes to defend against German bombers and had little time to develop the Whittle Turbojet. So England turned to the United States for help. It was up to the U.S. to improve the jet engine and put it on the production line. The Army Air Corps set a six-month deadline to produce the first American jet. Because of its success building complicated turbines, GE was asked to improve Sir Frank Whittle’s jet design. Starting in 1941, a group of GE engineers at Lynn called the Hush Hush Boys designed new parts for the engine, redesigned others and delivered a top-secret working prototype called I-A. On Oct. 1, 1942, the first American jet plane, the Bell XP-59A, took off from Lake Muroc in California for a short flight. The jet age in the U.S. had begun.

I is for Ice Testing — Jet engines go through a series of rigorous tests, including sand, wind, hail stone and ice ingestion. You might call it jet engine bootcamp. Every engine under development must go through the ice certification program before it can go on the wing of an aircraft. GE’s Aircraft Engine Testing, Research and Development Centre (TRDC), located in Winnipeg, has established itself as one of the leading cold-weather test centers for jet engines in the world. Getting blasted with ice... just another day of testing for jet engines. See for yourself.

J is for Jet Age — Early iterations of the jet engine took flight at the dawn of World War II to kick off the jet age in the late 1930s and early 1940s, but jet-powered aircraft saw virtually no combat action. That period of innovation did establish jet-powered aircraft as a viable technology, though. Once the war was over, the jet age began on a global scale with a period of massive growth, moving beyond the military into civil and commercial operations. Over the following decades, flight became a reality for millions of people as the cost of flying dramatically decreased.

K is for Kitty Hawk — A tiny, remote town in the Outer Banks of North Carolina, Kitty Hawk gained international fame after the Wright Brothers successfully completed the world’s first-ever powered flight on December 17, 1903. The Wright Brothers chose Kitty Hawk for its consistent winds and soft sand dunes, and they spent three years testing gliders in Kitty Hawk before finally making that famous first flight.

L is for Life Cycle — From an engine’s inception to its last time powering an aircraft, the life cycle of a jet engine is quite the journey. It starts humbly with sketches on a piece of paper, moves to prototyping and testing, and eventually, an engine ends up on-wing powering people through the sky. Maintained properly, a GE jet engine can be in service for upwards of 30 years!

M is for Manufacturing — Manufacturing has been, and always will be, at the core of what GE Aviation does. Thousands of GE Aviation’s manufacturing employees work day-in and day-out around the globe to produce the components that bring a jet engine to life. From the nuts and bolts all the way to 3D-printed fuel nozzles and ceramic matrix composites, it all comes together thanks to the passion and expertise of GE Aviation’s manufacturing employees.

N is for NOx — Thanks to cutting-edge materials and a focus on reducing our carbon footprint, GE Aviation’s newest jet engines have drastically cut NOx emissions. The GEnx, first announced in 2004, introduced the twin-annular pre-swirl (TAPS) combustor, a breakthrough technology that helped reduce its NOx emissions to as much as 55 percent below regulatory limits. The next generation of engines are taking fuel efficiency to the next level too. Technologies like additive manufacturing and composite materials reduce engine weight and GE Aviation’s FlightPulse flight analytics tool helps pilots optimize every drop of fuel during each flight, all helping contribute to cleaner skies and a greener planet.

O is for Open Systems — There’s no denying that a traditional airplane flight deck looks… complicated, to say the least. And because aircraft are typically in service for decades, it becomes a huge burden in both time and money to update flight decks with the latest technologies. That’s where GE Aviation’s Open Systems flight deck comes in. The Open Systems flight deck has architecture built for the digital age, with several large, touch-screen monitors and a heads-up display constantly monitoring the aircraft’s performance. Like today’s smartphones, the Open Systems flight deck allows pilots to download and use a wide variety of specialized applications that crunch numbers mid-flight, giving pilots the power to get the most out of each flight.

P is for Pikes Peak — Pikes Peak soars 14,109 feet into the Colorado sky. In 1918, legendary GE engineer Sanford Moss and his team spent the summer and fall running tests for a GE-turbosupercharged engine atop Pikes Peak in an attempt to replicate the same horsepower the engine could achieve at sea level. The whole operation was a huge challenge, but Moss and his team were able to successfully achieve the necessary horsepower and the Army announced it would proceed with GE’s engine design.

Q is for Quiet — If you asked someone to describe a jet engine, the word “quiet” probably doesn’t come to mind, but GE’s newest engines are making waves with dramatic noise reductions. Using improved designs to reduce noise for both passengers and people on the ground, the all-new LEAP engine is providing operators with dramatic noise reductions thanks to high bypass ratios and specially-designed chevrons near the engine’s exhaust, which also help improve fuel efficiency and reduce CO2 emissions.

R is for Rotorcraft — The rotorcraft is a class of aircraft that includes the autogyro, gyrodyne, rotor kite, most famously, the helicopter. GE Aviation has a long tradition of powering some of the world’s most recognizable rotorcraft, including the U.S. Army’s Apache and Blackhawk helicopters, as well as the U.S. Navy’s King Stallion helicopters.

S is for Single Spool — A single spool design means that all the rotating components in the engine’s compressor and gas generator rotate on a single shaft, all at the same speed. It results in a more simplistic, lightweight engine that can be repaired and maintained quickly. GE Aviation’s new T901 engine features a single spool design – a difference-maker in the U.S. Army’s decision to use the T901 to re-engine its Apache and Blackhawk helicopters.

T is for Thrust — When military pilots find themselves in the midst of a combat mission, they rely heavily on the engine’s thrust – the force provided by engines which moves a jet through the air – to allow them to successfully complete the sortie and safely return to their home base. Thrust is equally as critical to commercial pilots. Earlier this year, the GE9X set a new world-record for thrust, becoming the most powerful commercial jet engine after reaching 134,300 pounds.

U is for Utilization — Airplane utilization is a key performance indicator for airline operations, and improving this metric helps spread fixed ownership costs over an increased number of trips, reducing costs per seat-mile or per trip. So, when an aircraft is out of service due to an engine or system quality or delivery issue, it is undoubtedly having a negative impact on the customer bottom line.

V is for Variable Stator Vane — In 1948, GE hired German aviation pioneer Gerhard Neumann, who quickly went to work on the jet engine. He developed a revolutionary design called variable stator that allowed pilots to turn the vanes on the engine’s stator, change the pressure inside the turbine, and make planes routinely fly faster than the speed of sound. Today’s variable stator vanes convert the increased rotational kinetic energy into static pressure through diffusion and redirect the flow direction of the fluid, preparing it for the rotor blades of the engine’s next stage.

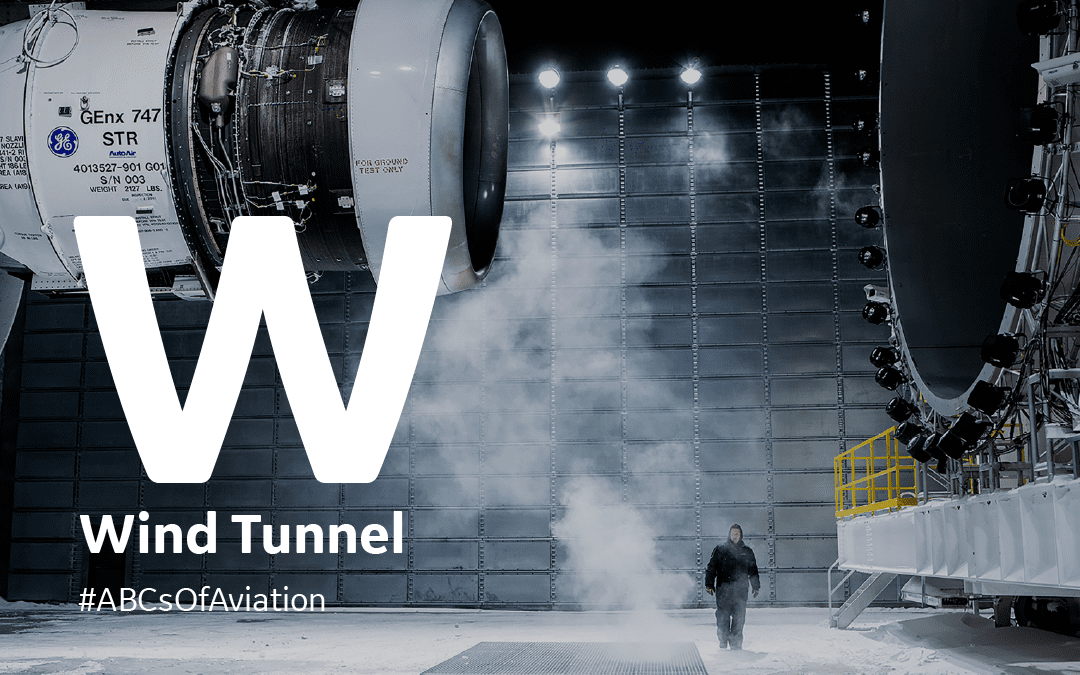

W is for Wind Tunnel — Aerospace companies like GE Aviation use wind tunnels to test models of proposed aircraft and engine components. At GE’s Winnipeg, Canada, test complex, engines endure the human equivalent of running a marathon in Siberia through clouds of freezing water, blinding wind and ice crystals. It's just some of the many rigorous tests jet engines endure before they are delivered to customers.

X is for “X”perimental engines — An aviation engineer’s ultimate passion is to work on the next big thing – a concept, design, material or component that will be the hallmark of an experimental engine. Experimental engines serve as the proving grounds for development of next-generation products, many that will someday become staples in GE Aviation’s portfolio.

Y is for Yield — Yield measures the ultimate effectiveness of a manufacturing process. It calculates the proportion of correct items (conforming to specifications) you get out of a process compared to the number of raw items you put into it. Throughout GE Aviation shops, first-time yield is the goal and a key metric aligned with Six Sigma and Lean initiatives.

Z is for Zulu — Zulu (short for "Zulu time") is used in the military and in navigation generally as a term for Universal Coordinated Time (UCT). The letter Z may be used as a suffix to denote a time being in the Zulu Time Zone, such as 08:00Z or 0800Z. The Department of the Navy serves as the country's official timekeeper, with the Master Clock facility at the U.S. Naval Observatory, Washington, D.C.